Ursa Major’s 3D Printed Hadley Engine Takes First Flight

Additive manufacturing is soaring higher and higher as it continues to cement its place in the space industry. Case in point, only two years since emerging on the Aerospace AM scene, Ursa Major has announced the first flight of its Hadley engine, which was made using 3D printing along with other techniques, during a test of the Stratolaunch’s Talon-A1 (TA-1) testbed. The news marks “a major leap forward toward the first flight test of a privately funded hypersonic vehicle,” according to the company.

To give some context, Colorado and Ohio-based Ursa Major was founded in 2015 by former SpaceX and Blue Origin propulsion engineer Joe Laurienti. The company puts itself forward as the leading independent rocket propulsion provider in the United States, as well as the first American company to fire an oxygen-rich staged combustion engine (previously only done in Russia). Ursa Major became more widely known in the 3D printing sector as well in 2022 with the announcement that its Advanced Manufacturing Lab in Youngstown, Ohio had delivered its first copper-based, 3D-printed rocket engine combustion chambers. Now it has shown its growth with the first flight of its 3D printed Hadley engine.

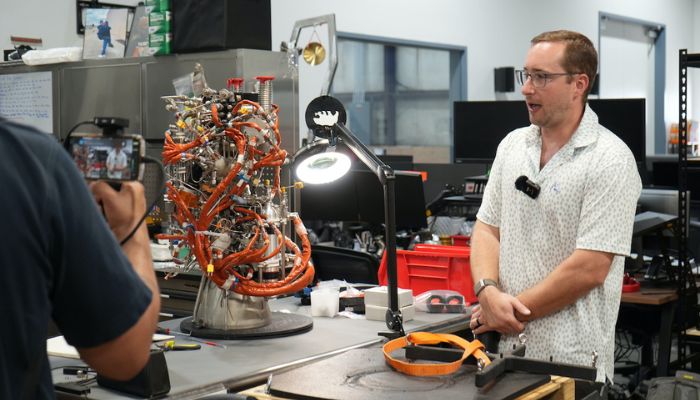

Joe Laurienti with the Hadley engine

The First Flight of the Ursa Major Hadley Engine

As mentioned, the Hadley engine’s first flight was powering the TA-1 testbed during a test over the Pacific Ocean. Though Stratolaunch has stayed quiet on many of the details of the test out of respect to its customers, the company did announce that the test reached high supersonic speeds approaching Mach 5. This is the limit wherein speed becomes hypersonic, or five times the speed of sound.

And though this is exceptional news for the advancement of private space companies, it is also interesting for the wider market for additive manufacturing in aerospace. That is because Hadley engine, the first product in Ursa Major’s family of propulsion systems, is yet another example of an engine that has been 3D printed. Indeed, the 5,000-pound-thrust (lbf) liquid oxygen and kerosene, oxygen-rich staged combustion cycle rocket engine has been designed specifically for small vehicles and 3D printing is a core part of its development. That is because it allows the company to speed up the manufacturing process to only a few days.

In terms of the 3D printing itself, Ursa Major does go into much detail in the press release. However, from previous announcements, we know that the Hadley engine was likely made using copper and metal 3D printing, potentially one on a laser powder bed solution as they have worked with EOS in the past. We know as well that the company is a customer of Velo3D’s recently announced Flow Developer tool. Regardless, the flight of the Hadley engine shows the continued relevance for metal AM in this sector as companies move towards hypersonic flight.

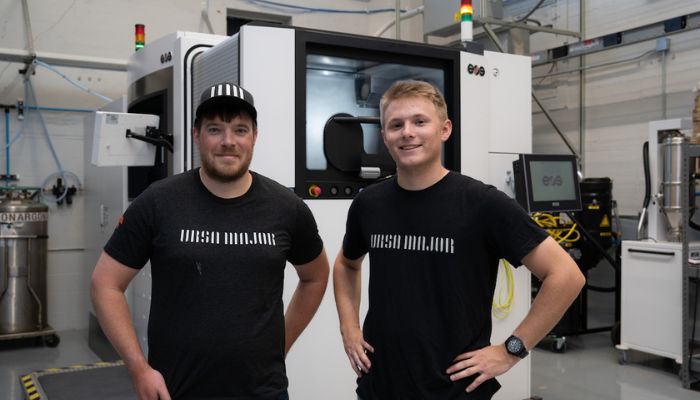

Ursa Major’s Additive Manufacturing Lab in Youngstown, Ohio

Laurienti, the founder and CEO of Ursa Major, concludes, “For the first time since SpaceX fundamentally transformed space launch with privately developed rockets, Ursa Major and Stratolaunch have come together to advance a critical national mission. Hypersonic flight has been a massive military and governmental challenge. Today, private companies were able to propel a leap forward.” You can find out more on Usra Major’s website HERE.

What do you think of the first flight of the Ursa Major Hadley Engine? What other advancements in AM in space do you expect we’ll see from the company? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.