Urban Reef on Using 3D Printing and Natural Materials for Greener Cities

Additive manufacturing is a focus of interest in many fields because of its potential not only in terms of digitizing manufacturing, but also for more sustainable production. For example, there are currently a number of projects using natural materials as 3D printing materials including clay, soil, food waste, coffee, and more! Additive manufacturing makes it possible to transform these materials, by recycling or taking them from nature, and make many previously unimaginable applications with them. This can be seen as well with Dutch startup Urban Reef, which has combined cutting-edge technologies, 3D printing and natural materials to imagine and design greener, more inclusive and welcoming cities. They have developed structures called Reefs that they hope will help revolutionize the cities of tomorrow, thus providing a viable solution to climate change and pollution reduction challenges. To learn more, we interviewed one of the co-founders, Max Latour.

3DN: Could you introduce yourself and your connection to 3D printing

Max Latour (left) and Pierre Oskam (right)

I’m Max Latour, one of the founders of Urban Reef and a computational designer with a background in architecture. I initiated my studies at the faculty of architecture at the TU Eindhoven, where I had my first brief encounters with 3D printing. After completing my bachelor’s degree, I moved to the TU Delft for my master’s, drawn by its emphasis on architectural design. Here I started to develop my interest in computational design.

Initially, my obsession was with designing organic shapes, but this quickly evolved into an interest in natural morphogenetic processes and the potential of translating those into design tools. Eventually I graduated my master’s degree at the Robotic Building Lab, a studio within the faculty of architecture using computational design tools and 1:1 prototyping using robotic manufacturing processes.

After graduating I started working at the Robotic Building Lab as a researcher. Concurrently, I started to explore broader applications of computational design tools and natural morphogenetic processes, often in relation to 3D printing. It is the conjunction and elegant synergy of these explorations and Pierre’s insightful work on rewilding urban spaces and his philosophical perspectives on the topic which eventually evolved into what Urban Reef is today.

3DN: How did Urban Reef come about? What is its mission?

Urban Reef began as a small experiment initiated by Pierre Oskam and myself. We met during a project at the TU Delft. Pierre, a graduate of the faculty of Architecture at the TU Delft, pursued his PhD Strategic Design at University of Aveiro and University of Porto, Portugal. His doctoral research delved into rewilding abandoned urban spaces, exploring the changing human position within the natural realm and the philosophical background of this. At the end of his Ph.D. he wanted to materialize one of his ideas and approached the Robotic Building Lab at the TU Delft at the time that I was working there.

The project at the TU Delft triggered discussion about the potential of the crossover of our interests, rewilding the urban environment through design using abstractions of natural processes. We decided to start a small experiment autonomously, where we 3D printed a series of prototypes according to these design principles and experimented with 3D printing with coffee, mycelium and seeds. These experiments were successful and validated the potential of the approaches. This enabled us to start focusing on it full time and proceed to the next phase of development.

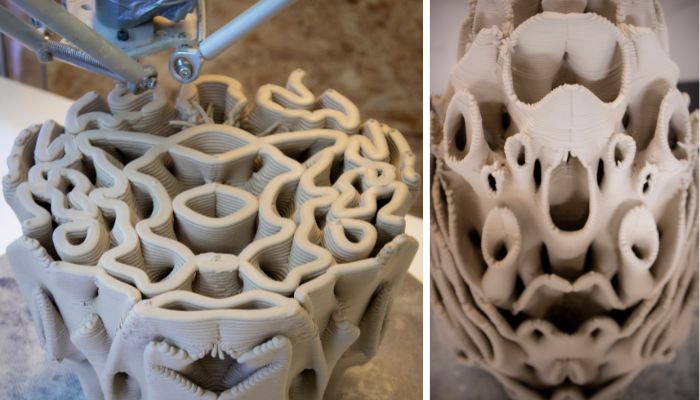

An example of organic structures made using 3D printing

3DN: Can you tell us more about the “Reefs” concept? How are they created and what is their purpose?

Reefs are structures that enhance ecological potential by hosting diversity in conditions. Varieties of interconnected spaces emerge from geometric complexity, which foster diverse microclimates due to variations in size, shape and orientation towards the sun, the wind, the rain and so on. This ultimately results in potential habitats for a wide range of organisms. The aim is to create conditions for ecosystems in the urban environment to autonomously thrive, with little human interference and determination, or the need for active systems.

A specific application of this concept is our Rain Reef. These are specially designed to connect to a downspout, collecting and buffering rainwater. The material’s porosity allows the rainwater to be passively distributed to the surface of the reef, enabling algae and mosses to grow directly on it. This process not only provides habitats and buffers rainwater but also contributes to humidifying and cooling the air through evaporation and transpiration, combating the urban heat island effect.

Reefs are capable of “coming to life.” In this case, Rain Reef absorbs moisture and becomes the ideal environment for fungi to grow, thus bringing the structure to life.

3DN: What natural materials is Urban Reef developing for 3D printing?

In our quest to integrate sustainable practices into urban architecture, Urban Reef has adopted a bifurcated approach to material research and application development. This separation allows us to deploy viable applicable solutions in the short term, while continuously exploring and advancing biobased materials for future implementation.

For our current structures, we have selected ceramics as the primary material due to its relative sustainability and compatibility with the built environment. Ceramics are not only common in construction but also possess essential properties for our applications — such as workability, printability, structural capacity, and porosity. One last threshold yet to overcome is the necessity for the firing process, which is still quite energy demanding. This is where our material research becomes pivotal.

In the short term, we are concentrating on making the most of local resources in the goal of reducing carbon footprints. A prime example of this is our collaboration with Blauwe Bagger, where we are researching the use of local dredge. Blauwe Bagger can subtract the clay from the dredge (a river or lake bed for example) from, converting this abundantly available resource into a valuable construction material. By doing this, we aim to reduce the environmental impact associated with material sourcing and transport, and enhance the circularity of our production process.

In the long term we aim to substitute the clay with a biobased material, preferably with an organic hardening process. For the experiments with these materials we usually collaborate with specialized partners with specific knowledge of these materials. For example, we collaborate with Junai.earth to print with Olive pits, oyster shells, and alginate. With Lindey Cafsia, we also printed with cow dung. Our goal is to ultimately substitute ceramics with these biobased materials, once ready for implementation.

Reefs blend seamlessly into the environment

3DN: How does Urban Reef see the future of urban architecture? What role will additive manufacturing play?

From the perspective of Urban Reef, we envision a future where architecture transcends its traditional boundaries and becomes a dynamic, living component of the ecosystems it inhabits. Our vision is not just about integrating green spaces into urban environments; it’s about redefining the very essence of what the urban environment can be. We see a future where buildings and urban structures harmonize with nature, actively contributing to biodiversity, sustainability, and environmental resilience.

In this future, 3D printing potentially plays a pivotal role, acting as a catalyst for this transformative vision. The potential 3D printing brings along in architecture lies in its ability to materialise complex geometries and intricate designs that were previously impossible or economically unfeasible with traditional construction methods. This capability opens up new avenues for architectural innovation, particularly when utilized by computational design strategies.

These strategies have the potential for architectural design to emerge from more bottom-up processes. This can result in designs that are more intricately related to physical or environmental conditions, like solar radiation, flow of forces, rainwater distribution, or ecological potential through microclimate diversity.

This architecture would be inherently natural, from a material-, morphogenetic- and environmental perspective and as a result from that also aesthetically. It would also lead to the redundancy of active systems that are presently essential for maintaining a desired comfort level, a necessity stemming from the current lack of environmental embeddedness in architectural design.

Example of a possible application of Reefs in an urban environment

3DN: What are the future projects of Urban Reef?

Currently we are capable of producing stand-alone sculptural structures. This focus has allowed us the freedom to iteratively experiment with various design strategies and evaluate their impacts.

At the moment we are setting up pilots in collaboration with market partners like construction companies, architects and municipalities. These pilots involve developing diverse applications of reefs. Each project is evaluated from ecological, functional, and market demand perspectives. Insights gained from these evaluations guide our future development towards cities that stimulate spontaneous ecologies.

3DN: Any last words for our readers?

We’re grateful for your interest in what Urban Reef stands for. As we stand at the beginning of a revolution in architectural design, it’s crucial to recognize that 3D printing isn’t just a tool for producing conventional designs with new techniques; it’s a catalyst to unprecedented possibilities in design and manufacturing.

We invite everyone to join us in exploring these opportunities to not only reinvent our urban environment but to reimagine them as natural landscapes. You can learn more about Urban Reef HERE.

What do you think of Urban Reef? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*All Photo Credits: Urban Reef