UpNano develops high-resolution desktop 3D printing for micro parts

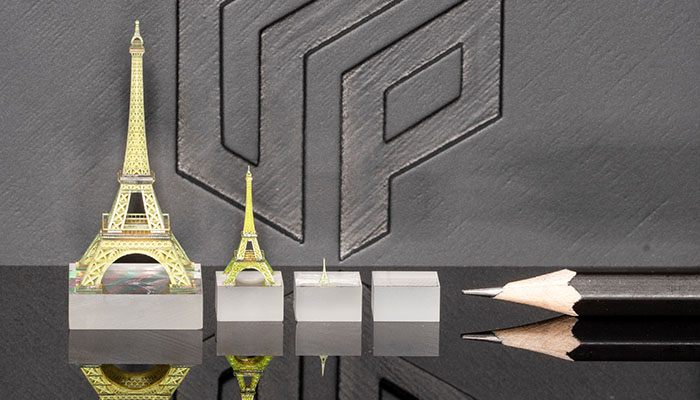

UpNano is a young company based in Vienna that has recently developed a high-resolution microscale 3D printing technology. Based on the 2-photon polymerization process (2PP), the new technique is capable of producing plastic parts with a volume ranging from 100 to 1012 cubic micrometers in just a few minutes, showcasing nanoscale resolution. The company is a spin-off of TU Wien, and is putting its technology at the service of R&D and applications in several sectors. We met with Denisa Mandt to learn more about the capabilities of their technology and plans for the future!

3DN: Can you present yourself and your relationship with 3D printing?

My name is Denise Mandt, I am co-founder of UpNano and responsible for marketing and sales. With a background in materials technology and biology, my first experiences with 3D printing were very early on. In my master thesis I worked with high-resolution 3D printing for the production of customized microfluidic chips. Today, together with Peter Gruber and Bernhard Küenburg, we are the founders of a young high-tech company, UpNano.

The UpNano team

3DN: Why is nano/micro-scale 3D printing a disruptive technology? What are the main benefits?

High-resolution 3D printing enables the production of parts that previously seemed impossible. The process is based on the principle of two-photon polymerization and, unlike classic SLA processes, is independent of the layer thickness. Once and for all, we put an end to the prejudice that “2PP printing is meant to be slow”. The trend of miniaturization has accompanied us for years, across all industries! The technology is on the pulse of time and meets the requirements of ever smaller and more precise components. With our process, we offer customers unmatched speed, the ability to produce to centimeter scale and biological applications. And all this in a compact desktop system.

3DN: How did the spin-off come about? What is UpNano’s main mission today?

The background of the research group at the TU Wien is a very biological one. The goal was to embed living cells directly into the printed matrix. To realize this, besides the biocompatible materials, the high printing speed was a basic requirement. Peter Gruber and Aleksandr Ovsianikov have succeeded in developing an innovative, patented process that enables a previously unmatched high throughput. As speed increased, so did interest in our technology – and the idea for the spin-off was born.

The combination of the usual high resolution and the throughput enables for the first time batch and small series production in addition to classic prototype applications. Fundamental for industrial applications! And this is exactly our mission – industrial manufacturing, we want to cover the sweet spot between traditional 2PP technologies and micro stereolithography, enabling fabrication of polymer micro parts from nano to centimeter scale.

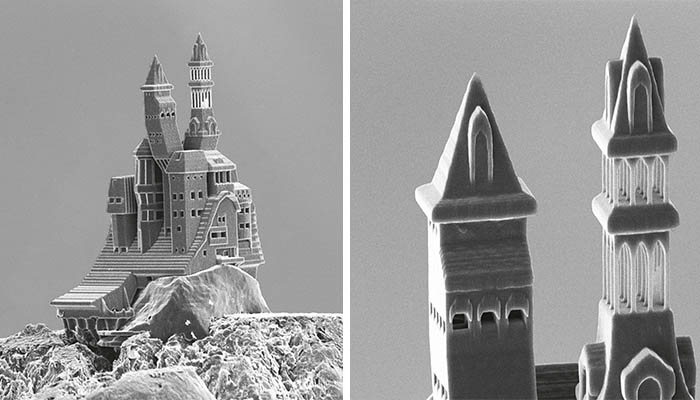

This castle measures 230 µm x 250 µm x 360 µm, and has been 3D printed on top of a pencil using 2PP | Photo Credits: UpNano

3DN: Could you tell us more about your projects?

The application areas in which our technology is used are as diverse as our customers themselves. From medical devices to optical and electronic components, we have already worked on a wide variety of projects for universities, research institutes and international companies. We are currently seeing increased demand from the medical sector in particular. Due to the current corona crisis, many researchers are focusing their capacities on novel testing, treatment and monitoring methods.

3DN: What sectors have the potential of being most impacted by microscale additive fabrication?

All applications where a high degree of customization is required or product cycles are very short are ideal for additive manufacturing. This applies for example to the medical industry as well as to the consumer electronics sector.

3DN: How do you view this segment of additive manufacturing evolving in the future?

We are convinced that 3D printing, and high-resolution printing in particular, is a future-oriented technology, as the development cycles of new technologies are becoming shorter and shorter. With additive manufacturing, valuable time can be saved, especially in the phase of development, thus improving interaction cycles and the product result. The development and prototype production is one thing, the much bigger long-term goal is to establish the technology in production. This is what we are working on at full speed – a machine line with even higher automation, specially developed to manufacture one and the same component in a reproducible manner. In addition to automation and speed, the materials and their characteristics are also decisive for industrial applications. A core competence of UpNano is therefore in-house material development and testing programs!

3DN: Any other projects, plans or words you would like to share with our readers?

In addition to investing in new technology, 3D printing also involves an investment in new know-how. Component design and construction can take completely new approaches and possibilities, steps in a new terroir where we actively support our customers! We are proud to be part of the AM development, and are pleased that 3D printing, with the full commitment of all companies, is succeeding in overcoming prejudices and becoming more and more established. You can find more information HERE.

What do you think of this startup? Let us know in a comment below or on our Facebook and Twitter pages! Don’t forget to sign up for our free weekly Newsletter, with all the latest news in 3D printing delivered straight to your inbox!