University of Alberta Researchers Improve 3D Printability of Pea Protein

3D printing can be used to overcome some of the key challenges facing the food industry. For example, specific shapes, flavors and consistencies can create special foods for children or people with swallowing problems, or to achieve an individual nutrient content. Additionally, 3D printed meat or plant-based alternatives are on the rise, encouraging us to rethink our eating habits. However, 3D printing plant-based proteins comes with several obstacles, like establishing the stability of a printed product. Now, researchers at the University of Alberta have revealed how 3D printing pea protein using cold plasma treatment achieved a better structure.

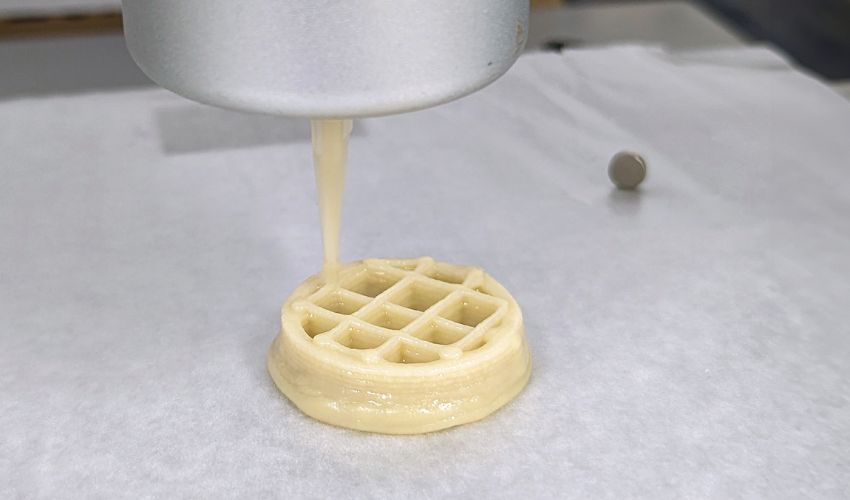

Pea protein is one of the cheapest and most nutritious sources of protein. It is also hypoallergenic. The pea protein used by the researchers comes from legumes grown on the prairies in Canada and the protein source is already used in the production of bread, cereals, plant-based dairy substitutes and meat alternatives. This range of applications makes it a real alternative to animal-based foods and could contribute to more and more people opting for a plant-based diet, provided the products are convincing in terms of taste, texture and form. This can be achieved through 3D printing, as we have seen in other applications of 3D printed food. The catch? Pea protein barely retains its 3D-printed shape after extrusion, so it’s difficult to realize its full potential as a plant-based alternative to meat. At least it has been until now, since researchers at the University of Alberta have found a way to solve this structural problem.

Pea protein is an inexpensive source of protein. Researchers at the University of Alberta have found a way for it to retain its shape after 3D printing, opening up new avenues for establishing plant-based protein sources.

3D Printing Gives Shape, Plasma Gives Stability

The researchers used cold plasma treatment to give the protein better structural properties. To do this, they mixed their pea protein “ink” with water activated with cold plasma. More specifically, they used plasma-activated microbubble water (PAMB) and mixed it with the protein to create a substance that was heated, then cooled and then printed. The goal was to create an appealing shape and texture that was also durable.

During the printing process, the researchers placed particular emphasis on adjusting the printing parameters that are crucial for the quality of the final products, including temperature, humidity and printing speed. Compared to the pea proteins enriched with distilled water, the PAMB-treated protein gels actually showed better structure and dimensional stability after printing. M.S. Roopesh, one of the co-authors of the study, attributes this to a structural change in the protein caused by the PAMB water. Furthermore, he categorizes the profitable results and points out the diverse new fields of application of pea protein: “By improving the gelation and 3D printability, pea protein can be used in several applications, including expanding the selection and boosting the structural properties of plant-based meat and cheese.”

The study, entitled “Improvement in 3D printability, rheological and mechanical properties of pea protein gels prepared by plasma activated microbubble water,” was published in June 2024 in the journal Food Bioscience and is available on ScienceDirect. HERE you can read the approach and results.

What do you think of this new approach to 3D printing pea protein? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*Cover Photo Credits: Pauline Chan