New Ultrasound Process Could Enable In-Body 3D Printing

Could you imagine a world where it would be possible to 3D print organs or tissues directly inside your body? Although this might sound like the most outlandish science fiction, researchers at Duke University and Harvard Medical School may have made it possible. They have developed a new 3D printing process using focused ultrasound and a bio-compatible ink, which together could be used for everything from bone healing to heart valve repair. The hope is that this will lead the way to safer and less invasive surgical procedures.

Though we have long extolled the benefits of additive manufacturing in the medical sector, including the growing bioprinting field, there are still obstacles, especially when it comes to printing in the body. This is because many of the current processes use either extrusion or photopolymerization, neither of which are well-suited to through-tissue 3D printing.

This technique used ultrasound-sensitive ink to build 3D structures at various depths, including through tissues in the human body

With extrusion, the reason it cannot be done inside the body is obvious, how would you put the apparatus in the body and if you need to cut open anyway why not make it externally? However, in-body 3D printing is also not possible with the various photopolymerization methods being developed. Why? Well, very simply, light is not able to travel through skin and organs as it scatters while passing through them. This is also the case for volumetric printing, which is what this latest 3D printing technology is based upon, and which uses photopolymerization and transparent inks.

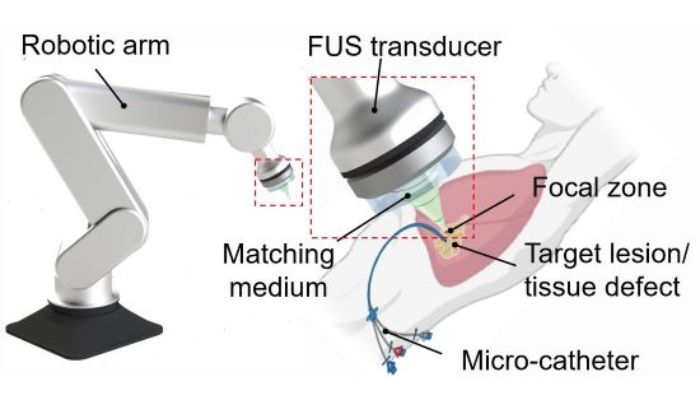

This new process, named deep-penetrating acoustic volumetric printing, or DVAP, could help overcome these issues. Randy King, Ph.D., a program directory in the Division of Applied Science & Technology at NIBIB, explains, “Focused ultrasound has been used for decades to treat a wide variety of conditions, underscoring its safety and utility as a clinical tool. This potential new application, built on years of technology advancements, could set the stage for something previously thought impossible: through-tissue 3D ultrasound printing.”

How Does Ultrasound 3D Printing Work?

As Dr. King mentioned, focused ultrasound is not new in the field of medicine. Defined by the National Institute of Health as “a non-invasive therapeutic technique that directs ultrasonic waves to a specific location,” it is already being used in the treatment of liver tumor, uterine fibroids and even Parkinson’s disease. However, this is the first time it would be used specifically with medical 3D printing.

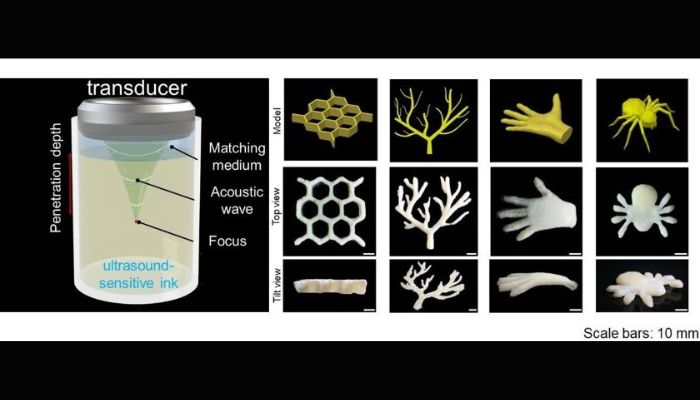

As for how DVAP works, it can be compared to other biomedical 3D printing processes, notably those using photo-sensitive inks and targeted light, including volumetric 3D printing. However, in this case what has been developed is a sonicated ink, or sono-ink, an ink that is sensitive to ultrasound. The ink itself is composed of four separate components: a compound to absorb ultrasound waves, a microparticle that helps to control viscosity, a polymer that provides structure, and a salt that absorbs heat to trigger solidification. Working together, this allows for the printing of biocompatible structures even through the body’s thick, multi-layered tissues.

A closer look at how the DVAP process works

This ink can also be adapted for different applications, such as adding bone mineral particles to heal bone loss. Moreover, it could be made more durable or degradable depending on a patient’s needs. A level of flexibility that is critical in medical applications and which works well with the researchers’ self-made confocal high-intensity ultrasound printer, which has been adapted to improve both speed and resolution.

The process was developed by Y. Shrike Zhang, associate bioengineer at Brigham and Women’s Hospital and associate professor at Harvard Medical School, and Junjie Yao, associate professor of biomedical engineering at Duke. As to how it works, Yao expands, “DVAP relies on the sonothermal effect, which occurs when soundwaves are absorbed and increase the temperature to harden our ink. Ultrasound waves can penetrate more than 100 times deeper than light while still spatially confined, so we can reach tissues, bones and organs with high spatial precision that haven’t been reachable with light-based printing methods.”

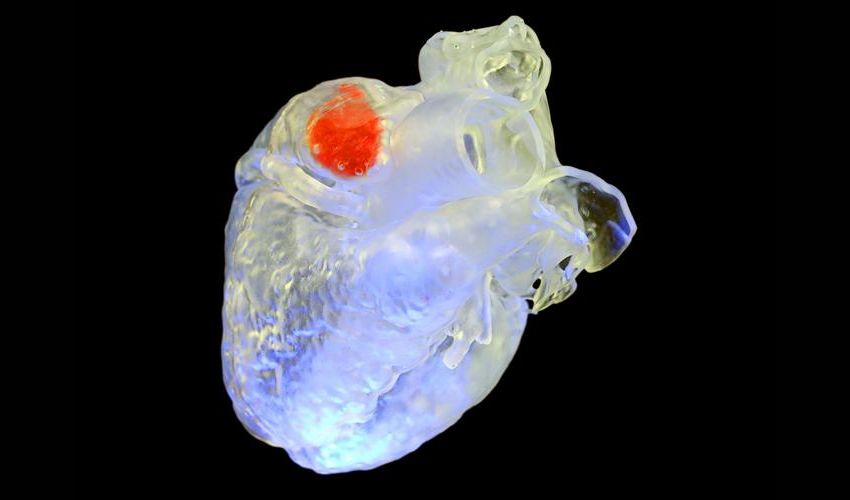

Furthermore, not only would DVAP allow for in-body 3D printing thanks to the use of ultrasound waves, but it could even be compatible with biological tissues. Zhang and Yao have already tested the process with the creation of tissues for a pig liver, as well as a mock surgery involving a goat heart. These experiments have shown promising results as well, meaning it may be possible in the future to use a process like DVAP to replace highly invasive surgical procedures.

Yao concludes, “Because we can print through tissue, it allows for a lot of potential applications in surgery and therapy that traditionally involve very invasive and disruptive methods. This work opens up an exciting new avenue in the 3D printing world, and we’re excited to explore the potential of this tool together.” You can find out more in the press release from the National Institute of Health HERE, or get access to the study HERE.

What do you think of the use of focused ultrasound for 3D printing? Let us know in a comment below or on our Linkedin, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*All Image Credits: Junjie Yao (Duke University) and Yu Shrike Zhang (Harvard Medical School and Brigham and Women’s Hospital)