Will Ultrasound-Guided 3D Printing Inside the Body Lead to Better Treatment of Diseases?

A recent study by American researchers has led to the development of a method of 3D printing directly into the body using ultrasound. In concrete terms, the team would be able to inject 3D shapes loaded with cells into the body and, using ultrasound, bring them closer to where treatment is needed. The aim is to administer drugs or the right cells as close as possible to a disease. Initial tests have been successfully carried out on mice and rabbits, suggesting that it may be possible to repair damaged tissue directly in their bodies. The technique, dubbed deep tissue in vivo sound printing (DISP), represents a major breakthrough for the medical additive manufacturing sector.

As we all know, 3D technologies are one of the most useful resources in the healthcare sector. They can be used to design tailor-made implants to be integrated into the human body, or tissue directly onto the skin, for example. However, the need for invasive surgical implantation is more often than not necessary and adds to the complexity of the whole process. That is why a team of scientists at the California Institute of Technology (Caltech) have come up with a printing platform that uses image-guided ultrasound to place 3D materials deeper into the body. Unlike infrared light, for example, ultrasound is able to penetrate muscles and organs.

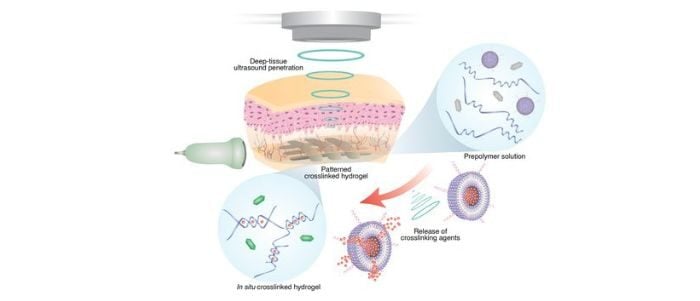

Diagram of the DISP process (photo credits: Elham Davoodi and Wei Gao)

Ultrasound-Guided 3D Printing: Operation and Testing

The researchers used a focused ultrasound beam and a specially formulated bio-ink. The latter is a hydrogel formed by polymer chains and cross-linking agents. In addition, ingredients specific to the disease to be treated are added. The cross-linking agents are encapsulated in liposome-based particles. These are lipids whose outer envelopes disappear under the effect of heat (around forty degrees). These liposomes prevent the bio-ink from forming as soon as it is deposited, thus enabling better control of cross-linking and increasing its speed. The team was thus able to create stars and drops of water.

The researchers explain that their DISP method is capable of printing biomaterials that are not only conductive, but also loaded with drugs, cells or bioadhesives, enabling them to treat a variety of diseases. They were able to deposit them in the muscles of rabbit legs, but also close to the diseased bladder of a mouse. Wei Gao, a biomedical engineer at Caltech, explains, “Infrared penetration is very limited. It only reaches right below the skin. Our new technique reaches the deep tissue and can print a variety of materials for a broad range of applications, all while maintaining excellent biocompatibility.”

Examples of 3D-printed shapes (photo credits: Elham Davoodi and Wei Gao)

In rabbits, scientists reached depths of up to 4 centimeters beneath the skin. For tests on mice suffering from bladder cancer, they loaded the bioink with doxorubicin, a drug used in chemotherapy to slow or stop cell growth. The team found that, by using the DISP method, cancer cells were eliminated much more quickly and to a greater extent than by injecting the drug in the traditional way.

Wei Gao concludes, “We have already shown in a small animal that we can print drug-loaded hydrogels for tumor treatment. Our next stage is to try to print in a larger animal model, and hopefully, in the near future, we can evaluate this in humans.” To find out more, click HERE.

What do you think of this new ultrasound-guided 3D printing method? Will it help accelerate treatment for diseases like cancer? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel. If are interested in finding more 3D printing news in the medical and dental sector, click HERE.

*Cover Photo Credits: Futura Sciences

Hi

Inform details of Speeding up Creality

3D Pro Printer with Suitable Modified Kit

and Appropriate Software for PLA 3D Printing

Thanks

Kh**********@***oo.com