UC Berkeley’s SpaceCAL 3D Printer Demonstrates Success in Orbit

A team of UC Berkeley researchers, spearheaded by Ph.D. student Taylor Waddell, has achieved a significant milestone in additive manufacturing with the development of the SpaceCAL 3D printer. Launched into suborbital space aboard the VSS Unity on June 8th as part of the Virgin Galactic 07 mission, this technology is expected to revolutionize how astronauts address fabrication and repair needs during extended space missions.

According to the research team, SpaceCAL, short for Space-Computed Axial Lithography, represents a cutting-edge advancement in 3D printing. This technology, developed by Hayden Taylor and his team at UC Berkeley in collaboration with Lawrence Livermore National Laboratory, employs light to create solid objects from a viscous liquid. The result is a faster and more versatile printing process compared to traditional methods.

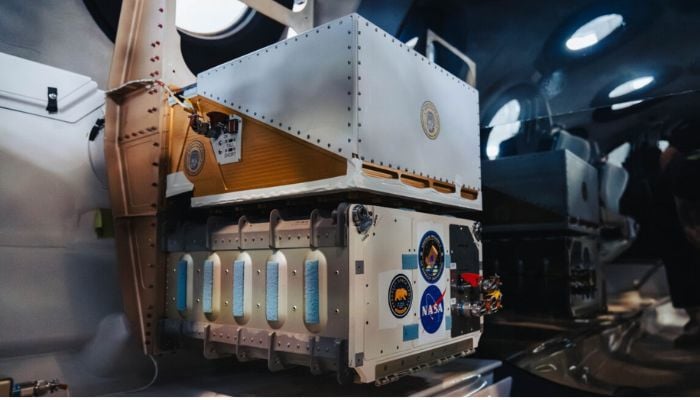

The SpaceCAL Microgravity 3D printer. (Photo Credits: Virgin Galactic)

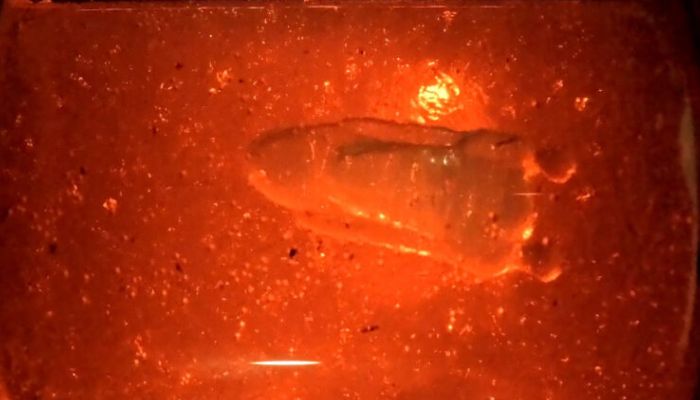

During its brief yet impactful 140-second journey in suborbital space, SpaceCAL autonomously produced and post-processed four test objects using a liquid plastic called PEGDA, showcasing its ability to operate effectively in microgravity—a critical factor for future space exploration endeavors.

“SpaceCAL performed well under microgravity conditions in past tests aboard parabolic flights, but it still had something to prove,” said Waddell. “This latest mission, funded through NASA’s Flight Opportunities program and supported by Berkeley Engineering and the Berkeley Space Center, allowed us to validate the readiness of this 3D printing technology for space travel.”

Versatility and Speed of SpaceCAL

CAL technology’s distinguishing features lie in its exceptional speed and adaptability. With the ability to fabricate parts in mere seconds, CAL empowers astronauts to create essential components in urgent situations swiftly, minimizing the necessity for carrying extensive spare parts. This attribute is paramount for long-duration missions where cargo constraints are incredibly stringent.

Additionally, CAL technology’s versatility extends beyond spacecraft repairs. The ability to print with a wide range of materials, from silicones and glass composites to biomaterials, opens up numerous possibilities for maintaining both spacecraft and crew health. “We can print O-rings, mechanical mounts, and even tools,” Waddell explained. “But CAL is also capable of repairing the crew. We can print dental replacements, skin grafts or lenses, or things personalized in emergency medicine for astronauts, which is very important in these missions, too.”

Space shuttle figurine printed by SpaceCAL while in sub-orbit. (Photo Credits: Taylor Waddell)

Looking ahead, the potential applications of CAL technology are both extensive and captivating. With support from NASA, the Berkeley team aims to push the boundaries further, venturing into realms such as bioprinting human organs in space. LLNL has already secured a NASA grant to experiment with this technology on the International Space Station, with the ultimate aspiration of printing organs in space and returning them to Earth.

Moreover, the team is actively developing single objects that contribute to crew health and well-being, such as dental crowns or surgical instruments. To learn more about this milestone, click here.

What do you think about UC Berkeley’s SpaceCAL 3D printer? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly newsletter here for the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel

*Cover Photo Credits: Virgin Galactic