UBQ Materials and Plastics App Launch New Highly Sustainable 3D Printing Material

UBQ Materials and Plastics App have joined forces to develop and launch a novel material in order to improve the functionality of sustainable 3D printing. The partnership derives from mutual recognition of the growing demand for zero waste supply chain manufacturing solutions, geared towards supporting companies’ sustainable development goals. The two companies are well suited to this endeavor, with UBQ Materials claiming to be the developer of the most climate positive thermoplastic material on the market, and Plastics App as one of the leading research and development companies in tailor made applicative innovations for polymers and plastics. Together the companies have now successfully launched a new material enabling sustainable and eco-conscious manufacturing through its considerably reduced carbon footprint.

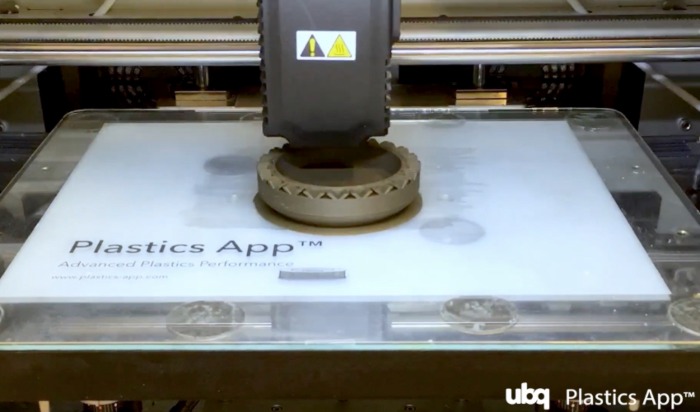

3D printing is already widely acknowledged as a highly environmentally responsible method of manufacturing, particularly when contrasted to traditional alternatives. Among other reasons this is because 3D printing requires considerably less energy and raw material as well as produces less waste. However, so far most sustainable 3D printing filaments have been based on PETG. This is a problem because PTG has limited properties meaning that use cases have largely been confined to dimensional models and dummies. UBQ Materials’ new material is a substitute for oil-based resins made from unsorted waste that would otherwise end up in landfill. The filament then undergoes further development by Plastics App which when applied to 3D printing acts to expand sustainable applications to functional users including jigs, fixtures and spare parts.

In increasing the number of applications, the two companies’ partnership will also increase the number of industries able to take advantage of 3D technologies. “Combining our end-to-end filament development capabilities with UBQ’s climate-positive material has opened sustainable opportunities for industries like automotive and housing, where fully functional prototyping is an essential part of both R&D and small-scale production,” commented Founder & General Manager of Plastics App, Dr. Yanir Shaked. “Using eco-conscious material to 3D-print functional prototypes from the early stages of development helps companies meet their sustainability goals without compromising on product functionality.”

The benefits of UBQ Materials and Plastics App’s new material do not stop there. According to Tato Bigio, the co-founder and CEO of UBQ Materials, “Introducing 3D-printing filaments to the market enables UBQ to test the limits and go beyond the boundaries of traditional plastic manufacturing techniques.” He goes on to explain, “The versatile applications of UBQ™ allow for its incorporation into a wide range of products, decreasing emissions and preventing landfill buildup. This partnership will expand the scope of companies that can refine their processes while reducing their energy use.” Evidently, this new material marks not only the acknowledgement of an increased need for sustainability in manufacturing, but also the expansion of technological advancements paving the way towards a greener future.

If you want to find out more information you can read the full press release HERE. What do you think about UBQ Materials and Plastic App’s new material? Let us know in a comment below or on our Facebook, Twitter and LinkedIn pages! Sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox!

*All pictures courtesy of UBQ Materials