Tumaker on the 3D Printing of Pellets Adapted to Production Requirements

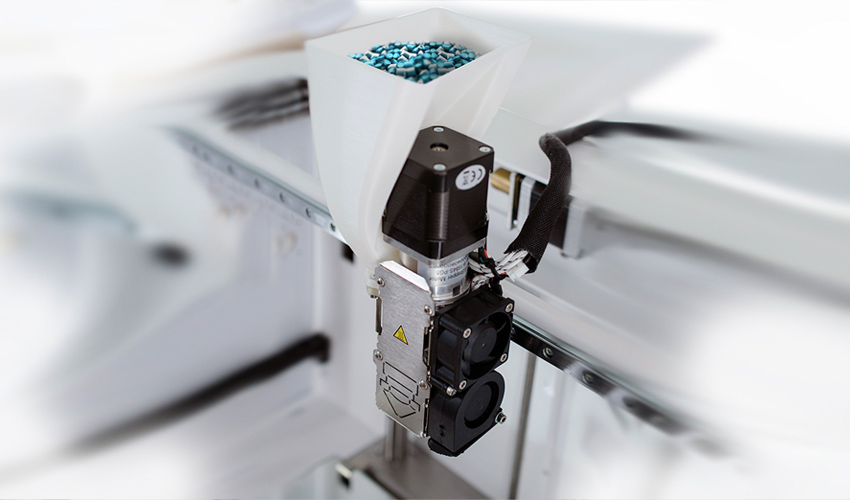

As 3D printing technologies gain prominence in different application sectors, more and more companies are considering taking advantage of the benefits offered by the manufacturing process. The main method they tend to opt for is the fused deposition modeling (FDM), due to its ease of use and low cost. Within this technology, other than filaments, which is the usual format in which most of the materials are usually found, it is also possible to 3D print with pellets. This is interesting because pellets are cheaper and easier to use and also reduce the possibility of jams which happen more regularly for filaments. One of the brands that has developed 3D printing solutions with pellets is Tumaker. In addition, its main competitive advantage is the team’s ability to adapt its solutions to the customer’s needs, offering a fully customizable machine. To understand more about Tumaker and how it sets itself apart in the additive manufacturing market, we spoke with Rubén García, Tumaker’s brand partner.

3DN: Can you introduce yourself and talk about what you do at Tumaker?

My name is Rubén García and I am the CEO of IT3D Group, one of the two companies that, together with Indart 3D, has managed the Tumaker brand since mid 2020. At Tumaker, basically, we are dedicated to the development of specific solutions for 3D printing users. As we like to say, we have what everyone else has, but we have exclusive developments that only we have.

Rubén García next to the DUAL 3D printer

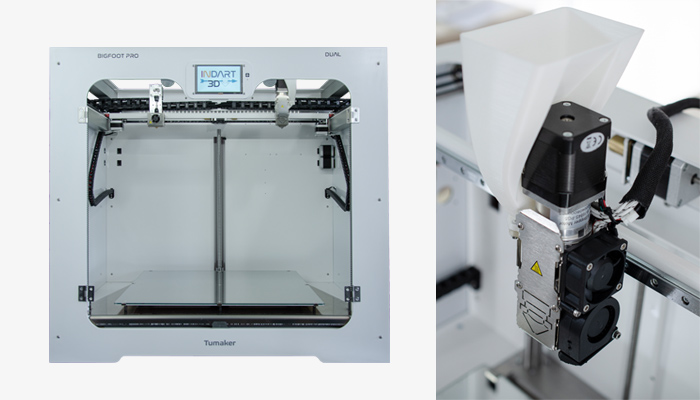

3DN: At Tumaker, you are experts in additive manufacturing with pellets, can you tell us more about your DUAL line of 3D printers? What benefits does this technology bring to the industry?

It’s true that 3D printing with pellets is one of the ways in which we differ from others on the market, together with DUAL printing with double independent heads. Basically we have managed to break the material barrier in 3D printing. We can print with materials that do not exist in filament, materials developed by the customer itself or materials that require specific certifications or approvals for use in various sectors. Undoubtedly, it is an essential tool in new materials development departments, in universities, in companies in sectors such as automotive, railway or aeronautics, in the health sector, in Technology Centers, and even more!

3DN: What possibilities does a company have when it comes to adapting manufacturing solutions to its business? Can you tell us about any success stories that reflect this?

Today, any company has the possibility of adopting additive manufacturing in whatever activity they are involved with. We have success stories in sectors as diverse as textiles, automotive, education, research, mechanics, decoration, construction, advertising, bottling, chemical, food, defense…I don’t think I could define a single sector that could not implement 3D printing in its production process.

For stories wherein we saw significant success, we could highlight the University of Vigo which uses pellet 3D printing in their biomedical research processes (you can see the full story on our blog). Another case of success in the use of our pellet 3D printer for research in new materials would Repsol Química. On the industrial side, there is the case of Power Electronics for the manufacture of specific parts for electric chargers or Flekos, a small and almost centenary textile industry that uses 3D printing to manufacture specific parts for their looms.

3DN: How do you see the field of new materials development thanks to advances in additive manufacturing technologies?

Undoubtedly the appearance of our pellet printer has meant a before and after in this sense. We have to take into account that with this equipment we avoid having to turn the material into filaments. This saves time, saves costs and, most importantly, prevents the material from degrading in the process of transformation from pellets to filament.

Most of the Spanish Universities with a new materials department have our equipment. Not only that, German universities and research centers of great prestige in Switzerland, Spain and Colombia, use our printer for their research.

3DN: Where do you see Tumaker in the next 5 years, and is there anything new we can expect from your brand in the near future?

We see it as a major player in the industry. We will continue to offer alternative and specific solutions for specific needs. This means that we will be able to consult with our customers beforehand in order to adapt the solutions to their real needs.

As for future developments, we would like to highlight the new service for the development and manufacture of customized printers. This is technological consultancy work based on customer requirements with the aim of manufacturing specific equipment that is not available on the market.

Finally, we would like to add that at both ADDIT 3D in Bilbao and FORMNEXT in Frankfurt, we will introduce a totally disruptive equipment that currently does not exist in the market. A printer that breaks with the current schemes of the sector. Unfortunately I can not say more, but I invite everyone to visit us at these two fairs and come to know the full range of specific solutions we offer.

3DN: Any last words for our readers?

We would simply like to thank our partners and customers for the trust they have shown in us during this time. For our part, we remain firm in our commitment not to remain stagnant and to continue innovating in order to offer equipment and solutions that really adapt to what our customers request. You can find more information HERE.

What do you think of Tumaker and its pellet solutions? Let us know in a comment below or on our Linkedin, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.