TPM3D Enables Edser to Deliver Faster and Better Orthotics Using SLS 3D Printing

Our lives are becoming increasingly connected, faster, more customizable, and adaptable to our individual wishes and needs. This phenomenon is evident in our communication, professional life, consumption, and in healthcare. Modern medicine aims to provide customized solutions that focus on better patient care and help those affected to enjoy a better quality of life. One way to customize medical devices and care is through additive manufacturing. The Spanish company Edser, a proven manufacturer of orthotics and insoles, has therefore turned to 3D printing, achieving greater flexibility, adaptability, and quality in its production.

Edser has nearly 30 years of experience manufacturing clinical orthotics, medical insoles, and custom-made fashion and performance soles. With strong international expertise, the company serves a wide range of customers, offering orthotics for patients with scoliosis, cerebral palsy, or strephenopodia/strephexopodia, as well as protective masks, shin guards for athletes, and insoles for normal shoes, high-heels, diabetic foot and other special conditions.

Edser’s wide range of products

To respond to the growing demand for fast, customized products, Edser has turned to 3D printing. In TPM3D, the Spanish company has found a strong ally to transform its traditional production into a digital workflow. Through its strategic partnership with the Chinese manufacturer of 3D printing solutions, Edser has been able to switch to high-volume, high-precision, and customized manufacturing. Edser can now manufacture its products faster and more cost-effectively using SLS 3D printing, thereby increasing user satisfaction.

A Digital Workflow for Faster Results

How was this achieved? The recipe for success is based on an efficient workflow, and powerful 3D printing solutions are at the center of this. Let’s examine the process using the example of customized insoles.

First, the customer or a podiatrist scans the foot. Edser has developed its own scanning app, WIKYSCAN, for this purpose. It is based on LiDAR technology, so compatible devices such as iPhones or iPads can be used for scanning without issue. The 3D data is then processed. A podiatrist supports this process and can adapt the design of the insole according to individual medical needs or doctor’s prescriptions.

This is followed by printing. Edser relies on the TPM3D S600DL system, an SLS printer with two 140 W lasers and a build platform measuring 600 x 600 x 800 mm. The printer is classified according to EU safety standards and is also TÜV CE certified. The proprietary algorithm for coordinating the two lasers ensures optimal print quality, and the scan speed of up to 2 x 25 m/s guarantees high throughput. For Edser, the size of the build platform was a decisive criterion: “It is one of the few 3D printers on the market with such capability in volume printing, for manufacturing large parts and revolutionizing the orthotic world. It enables the creation of designs in one piece that are fully adapted with complex geometries.”

Depowdering is one of the manufacturing steps (credits: Edser)

TPM3D PP Pro is used as the material. It is characterized by its excellent strength and chemical resistance. It absorbs very little water, is very light, and can be easily reshaped with heat after printing—ideal for comfort adjustments. The powder also contributes to a positive overall ecological balance, as only 20% new powder is required per batch. Intelligent nesting and forward-looking print planning can achieve almost 100% material utilization. This not only minimizes waste, but also drastically reduces costs.

According to Edser, the PP used is in no way inferior to its traditional counterpart: “PP Pro is quite similar to traditional polypropylene used for making insoles and customers like it, because they can adapt and work as usual. Like other technologies, using PP for printing requires a very good understanding of environmental conditions and the rugosity of the part, but we achieved similar results in terms of mechanical properties from TPM3D PP Pro material and traditional PP.”

Post-processing takes place after printing. TPM3D’s powder post-processing station (PPS) supports the workflow and handles powder removal, powder recovery and mixing, and real-time feeding of new powder. This is particularly valuable for Edser’s series production requirements, as it significantly reduces manual handling and ensures a clean, efficient workspace. Other processes used in the finishing of the printed part include vapor smoothing and sandblasting. The 3D-printed medical devices can then be delivered directly to the patient concerned.

Edser’s workflow (credits: Edser)

SLS Printing Reduces Production Time and Costs and Improves Patient Satisfaction

Edser was able to overcome various challenges thanks to TPM3D SLS 3D printing solutions and can now supply patients with medical products within a very short time. In addition to rapid product development and manufacturing, other notable successes include improvements in overall efficiency and performance. The large build volume of the S600DL allows for multiple parts per run, whether large parts or small batches, and dual laser scanning has reduced printing speed per layer by almost 50%.

Since SLS printing facilitates the production of complex geometries (hollow structures, lattices, etc.) without support structures, the performance of 3D-printed products has also been improved. In insoles, lattice structures allow for fine-tuning of the hardness in different areas, while the product remains breathable and lightweight. This also impresses customers. The end products—especially insoles—adapt precisely to the shape of each patient’s foot, offering comfort and therapeutic performance.

TPM3D offers different solutions to reduce production time and costs (credits: TPM3D)

Another significant advantage for Edser was the reduction in production costs. This is due to the S600DL, which offers a first-class ROI, especially in combination with TPM3D’s high-yield PP Pro material and efficient powder management system.

For Edser, investing in TPM3D SLS 3D printer has paid off. It enables patients to receive better, more targeted care, and digital production is also a significant step toward the future. “Looking ahead, we expect that 90% of our products will be manufactured using AM technologies,” emphasizes Sergio Sanchez-Osorio, CEO at EDSER Labs.

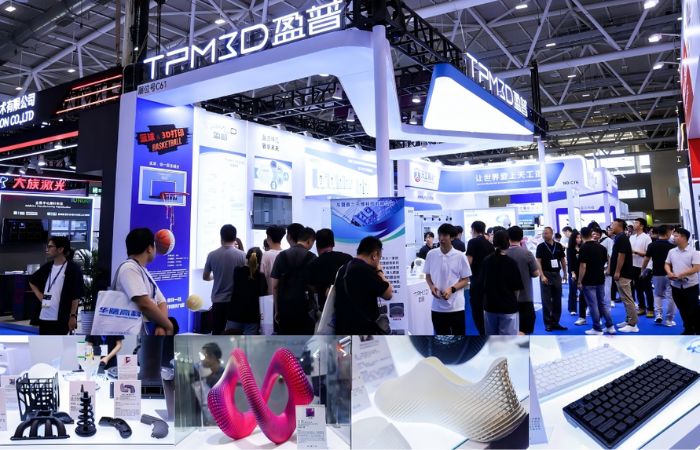

3D printing in the medical field and SLS printing will continue to develop significantly in the coming years. TPM3D sees it as its responsibility to actively shape these developments and is constantly improving and expanding its portfolio. TPM3D was recently represented at Formnext Shenzhen, where it was able to showcase its innovations to Chinese and international audiences, including their dual-laser SLS printer and the PPS, an efficient powder processing station. The company also presented a lot of different SLS applications, from industrial, art and design, to consumer goods, medical and electronics. You can find out more about TPM3D and the users of its solution HERE.

What do you think of TPM3D’s 3D printing solutions and their applications in the medical sector? Let us know in a comment below or on our LinkedIn or Facebook pages! Plus, don’t forget to sign up for our free weekly Newsletter to get the latest 3D printing news straight to your inbox. You can also find all our videos on our YouTube channel. Interested in more medical and dental 3D printing news? Visit our dedicated page HERE.

*Cover Photo Credit: Edser