#TOP5 Videos: the dental 3D printer NextDent 5100, 3D printed sushi…

We found the TOP 5 videos of the week about 3D printing and the way additive manufacturing is shaping and changing our society. This week we touch on the dental 3D printer NextDent 5100, 3D printed sushi and much more! If you enjoy these, you can view even more 3D printing videos on our Youtube channel. Hope you’ll enjoy and have a great Sunday!

Top 1: NextDent 5100 dental 3D printer helping patients and professionals!

The 3D printer NextDent 5100 developed by 3D Systems has become a real work tool for this American dentist. Thanks to this solution, he can create devices quickly and accurately. A patient who has an appointment in the morning can leave with his dental prosthesis in the afternoon. This is considerable time saving for all professionals and patients! The machine integrates well into the working environment and its software is apparently very easy to use:

Top 2: Improve surgical operations with 3D printing

Rady Children’s Hospital is one of the first hospitals in California to open a laboratory dedicated to 3D technologies. This facility allows surgeons to print 3D anatomical models with a complicated operation. This allows them to better prepare their operation and understand each step of it. Matthew is a patient who suffered from heart disease and was able to have a successful operation, thanks in particular to a 3D replica of his heart:

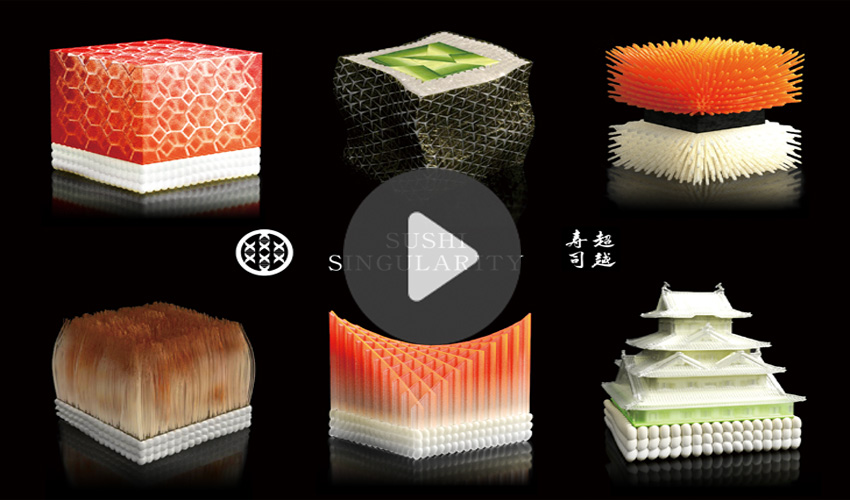

Top 3: 3D printed sushi

The Open Meals machine should be able to print your sushi in 3D! The Asian company behind this innovation apparently uses proteins, minerals and vitamins to develop tasty little bites. The consumer can even take a health test before ordering and send a saliva sample so that the company prints sushi that meets his food needs. A small revolution in food 3D printing?

Top 4: 3D printing and robotics

Haddington Dynamics is the company behind Dexter, a robotic arm that integrates 3D printed parts. He is able to grab objects with a pair of pliers and move them wherever he wants. Its designers used 3D printing and more particularly Markforged machines. This allowed them to reduce the number of robot components – from 800 to 70 – while reducing costs by 58%:

Top 5: Children get a taste of 3D printed Food

At an event that brought together more than 16,000 students, one of the stands showed the Foodini 3D food printer, which printed structures in 3D with hummus. The children were able to taste these little starters and we were quite surprised by their taste! A successful test for Natural Machines which continues its development in the culinary 3D printing sector:

What did you think of this week’s #TOP5 videos? Drop a comment below or on our Facebook and Twitter pages! And don’t forget to sign up to our free weekly Newsletter to keep updated on all the latest news in the 3D industry coming straight to your inbox!