The Top Examples of 3D Printed Rockets

Since the moon landing in 1969, humanity has never stopped reaching for the stars. What has changed, however, are the means of getting there. Since Apollo 11, rockets have changed immensely with innovation being the name of the game and in most recent years that has created additive manufacturing. More and more we are seeing 3D printed rockets, both those that are being developed and that have already been sent into space. In the following listing (in no particular order), we took a look at some of the most exciting projects, including everything from fully 3D printed rockets to engines and other parts that have been made and optimized using additive manufacturing.

Agnibaan From Angikul Cosmos

Agnibaan is one of the most recent 3D printed rocket projects, coming directly from Agnikul Cosmos, an Indian aerospace manufacturer that believes that going to space should be within everyone’s reach. It is for that reason that the company turned to 3D printing. Agnibaan (meaning “an arrow of fire” in Sanskrit) is claimed by the company to be the world’s first rocket with a single piece 3D printed engine, although Agnikul has not announced which technologies were used for the project. Agnibaan’s successful launch on May 30th at 7:15AM marks a huge step forward for additive manufacturing in the Indian space industry.

Photo Credits: Agnikul Cosmos

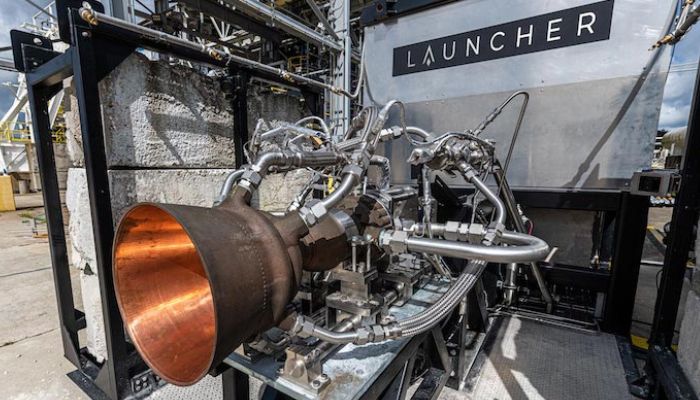

The E-2 Rocket Engine From Launcher

Launcher is a company founded in 2017 that worked in partnership with the US Space Force, the US Air Force and NASA to develop high-performance rockets and orbital transfer vehicles, it was acquired by Vast in 2023. But before then, by integrating state-of-the-art liquid propulsion technology and using 3D printing, the E-2 liquid rocket engine was created. This is a closed combustion engine with a combustion chamber made of a copper-chromium-zirconium alloy, which reduces costs and dependence on supply chains. Launcher is the first company in the launch vehicle sector to use 3D-printed copper alloys to manufacture the combustion chamber of a rocket engine. The combustion chamber also has integrated cooling channels to increase thermal efficiency. Together with AMCM, Launcher developed the AMCM M 4K 3D printer, which was then used to print the combustion chamber. The coaxial injector of the E-2 engine was produced on a Velo3D Sapphire 3D printer. In April 2022, the 3D printed E-2 engine reached full thrust during testing at NASA’s Stennis Space Center, whereupon Launcher announced the successful completion of the test run.

Photo Credits: Launcher

Ariane 6, the European 3D Printed Rocket

ArianeGroup is a joint venture between Airbus Group and Safran. With Ariane 6, ArianeGroup produced Europe’s latest heavy-lift launcher, which successfully made its maiden launch in July 2024. The Ariane 6 has a flexible design and can transport very large loads. ArianeGroup also used industrial 3D printing to manufacture Ariane 6. Numerous components of the engine were additively manufactured in this way, which led to a reduction in costs and minimized production cycles. The combustion chamber was developed and manufactured in Germany. The casing of the liner was printed using a cold spraying process and the monoblock injection head was printed using a laser sintering process. This injection head with all its injection elements was manufactured by EOS.

Photo Credits: ArianeGroup

Skyroot Aerospace and its 3D-Printed Rocket Engine

Founded in 2018, Indian company Skyroot Aerospace has set itself the goal of opening up space to everyone by offering fast, precise and affordable space launchers. It has developed several models under its Vikram range. But what interests us most are the rocket engines. Called Dhawan, they are 3D printed. They are cryogenic engine that uses both liquid natural gas and liquid oxygen. Both propellants require temperatures below -150°C for storage and operation. For both the Dhawan-I and the second version, metal additive manufacturing was chosen. Both engines have been successfully tested. The Dhawan-II engine is due to be installed in the Vikram-II rocket, scheduled for launch at the end of the year.

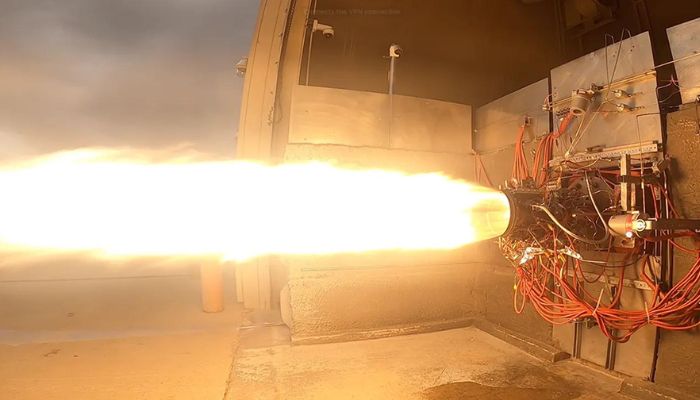

The 3D Printed Hadley Engine From Ursa Major

Ursa Major is another American startup that has been gaining attention for its work on 3D printed rockets. In its most recent news, the company announced in March 2024 that its partially 3D printed Hadley engine had successfully taken flight, approaching Mach 5. Although it is not clear what exact technologies nor materials were used in the creation of the Hadley engine, we know that 3D printing was an important part of it and it was likely done using copper and metal 3D printing, most likely with laser powder bed fusion due to the company’s work in the past with EOS. A huge milestone in the use of 3D printing to create engines for the private space sector!

A hot fire test of the Hadley Engine (photo credits: Ursa Major)

NASA’s Rotating Detonation Rocket Engine (RDRE)

As a leading institution in space travel and flight science, NASA is constantly setting new standards in propulsion technology. One recent example is the fact that NASA has produced the first full-size Rotating Detonation Rocket Engine (RDRE) using 3D printing. In the future, the engine could redefine the design of propulsion systems. The RDRE uses an advanced propulsion concept in which thrust is generated by the phenomenon of supersonic combustion. This allows higher performance to be achieved with lower fuel consumption. The engine was manufactured using laser powder bed fusion, utilizing the GRCop-42 copper alloy developed by NASA, which allows the engine to operate under extreme conditions for extended periods of time. In the fall of 2023, NASA conducted a series of tests at the Marshall Space Flight Center to verify that the engine could withstand the extreme temperatures and typical requirements, such as the integration of a lambda sensor. The tests were successfully completed and the RDRE thus offers the potential to support future missions to the moon or Mars.

EOS and Hyperganic 3D Print An Aerospike Rocket Engine

In 2022, EOS and Hyperganic made headlines by using artificial intelligence and 3D printing to produce an aerospike rocket engine with a particularly complex design. Hyperganic, a German company founded in 2015, made it possible to recreate a design inspired by nature with its algorithmic design software. The Aerospike rocket engine therefore impresses with its unusual and highly complex design. In a first step, the engine was 3D printed from a nickel alloy using the EOS M 400-4 machine and the alloy NickelAlloy IN718. In a later stage, the engine was manufactured from copper on a larger scale.

Photo Credits: EOS

AI and 3D Printing for TKL-5 Liquid-Propellant Rocket Engine

Using computational engineering and additive manufacturing, LEAP 71, a Dubai-based company, has made significant advances in space technology. The company has developed a rocket engine using the AI-based software Noyron. The aim of the project was to demonstrate the capabilities of the Noyron software, which made it possible to design and produce the TKL-5 rocket engine completely digitally and without human intervention. Thanks to the AI algorithms, no CAD design was required, which optimized the entire production of the engine to just two weeks. The engine was produced by AMCM on an EOS M290 3D printer made of copper, which in combination with active cooling resulted in a powerful engine. The engine was then post-processed by the University of Sheffield’s Race to Space team and successfully tested on Airborne Engineering’s premises. There it achieved a thrust of 20,000 HP, making it ideal for use in orbital rockets. LEAP 71 believes that this 3D-printed rocket engine has the potential to accelerate the pace of innovation in space travel and improve the accessibility of space.

Photo Credits: LEAP 71

The Orbex Prime Rocket

British aerospace company Orbex has developed the low-carbon, high-performance rocket, Orbex Prime. The rocket was made using Nikon SLM Solutions’ SLM800 metal 3D printer. Prime is powered by a 100 percent renewable fuel, biopropane, which can reduce CO2 emissions by 90 percent. In addition, the rocket is designed to be reusable by incorporating a recovery system, also programmed to leave zero debris in Earth orbit. Prime was first publicly unveiled in 2022 in the United Kingdom.

Photo Credits: Orbex

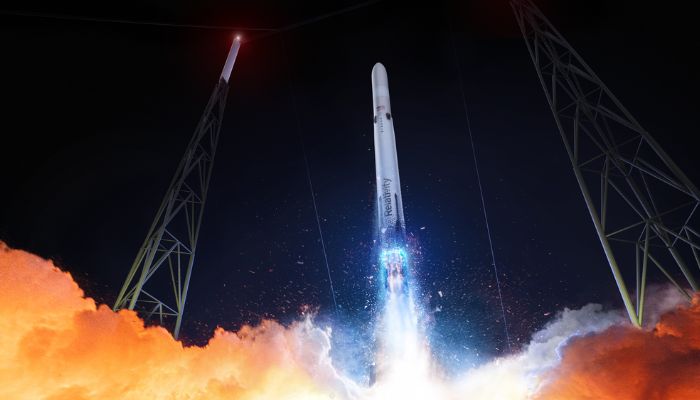

3D Printed Rockets From Relativity Space

Who at this point has not heard of Relativity Space? The Californian company has quickly made a name for itself since its founding in 2015, working towards its goal of creating a fully 3D printed rocket. And it’s nearly there! Terran 1, the company’s first rocket, was successfully launched in March 2023, although it did not reach orbit. This rocket was almost entirely 3D printed using DED and laser powder bed fusion and at the time of its launch was the tallest 3D printed metal structure ever built. Now, the company’s work is continuing with the Terran R which is expected to be 90% 3D printed and able to carry 20 times more payload than its predecessor. The Terran R will be launching from Launch Complex 16 at Cape Canaveral Space Force Base starting in 2026, flying straight into the future of space exploration.

An image of what the Terran R will look like (photo credits: Relativity Space)

Navier, the French Engine Made With Additive Manufacturing

Latitude (formerly Venture Orbital Systems) is a French start-up that specializes in the design of microlancers. Its first model is the Zephyr, measuring 19 meters long and 1.5 meters in diameter. It is equipped with a motor manufactured by metal 3d printing – more specifically, by LPBF. Named Navier, it is 45 centimetres high and weighs 30 kilos, with a thrust of 1.2 tonnes. It was manufactured from Inconel 718 on an SLM 500 machine in just a few days. At the start of 2023, Latitude had successfully fired the Navier, a fine achievement for the Reims-based startup.

Photo Credits: Latitude

The Rutherford Engine From Rocket Lab

The Californian startup Rocket Lab, a private aviation company, developed the world’s first battery-powered rocket, the Electron rocket, which successfully completed its first launch in 2017 with the 3D-printed Rutherford engine. The engine is named after the New Zealand scientist Ernest Rutherford and the 3D-printed components include the thrust chamber, two pumps, the injector and the main propellant valves. For the first flight, Rocket Lab used a ten-day launch window to launch the rocket from the Mahia Peninsula in New Zealand. The second flight, which took place in 2018, was an orbital spaceflight. After this, the company decided to go into commercial operation. The use of additive manufacturing in the production of the Rutherford engine has saved time and weight, which is important in aerospace, and the company wants to continue producing rockets that launch satellites into space.

Photo Credits: Rocket Lab

A 3D-Printed Combustion Chamber

OPUS Aerospace is another French company specializing in the design of launchers and spacecraft. It has developed two different launchers, Mesange and Sterne. Mesange will serve as a test and pave the way for Sterne. In both cases, the launcher incorporates the Torgos engine, whose combustion chamber was made using metal 3D printing in a single operation. Mesange is scheduled for launch from French Guiana in 2024, and will be used to perfect the Sterne launcher.

Photo Credits: Opus Aerospace

Stoke Space 3D Prints Combustion Chambers for Reusable Rockets

With NOVA, the American company Stoke Space is offering a fully reusable rocket for daily flights into space. To achieve this, the company is also using 3D printing. Stoke Space prints combustion chambers made of copper in order to print the chambers quickly on the one hand and to enable reusability on the other. The copper alloy of the combustion chambers is particularly conductive and can therefore be reused. Due to the regenerative cooling channels, the combustion chambers have curved manifolds and internal cavities. However, AM makes it possible to implement this complex design. The Seattle-based company is testing its developments in nearby Moses Lake.

Photo Credits: Stoke Space

What do you think of these examples of 3D printed rockets? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly newsletter here for the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

You forgot one – New Frontier Aerospace’s “Mjölnir” – a 3D printed full flow staged combustion engine.

https://www.nfaero.com/mjolnir

https://spacenews.com/new-frontier-aerospace-tests-rocket-engine-for-point-to-point-travel/