Top 5 Videos: Design rules for large format 3D printing…

This week we found the top 5 videos about 3D printing and the way additive manufacturing is changing production. The technology has infiltrated many sectors, from medical to automotive – check our selection of the week to keep up with the innovations! If you enjoy these, you can view even more 3D printing videos on our Youtube channel. Hope you’ll enjoy and have a great Sunday!

Top 1: Webinar – The Benefits of 3D printing with Composite ABS Filaments

Over the years, materials compatible with 3D printing technologies have been expanding to enable more applications, especially in industrial sectors that require technical-grade materials. In fact, many studies report that material choice is one of the key drivers of the adoption of additive manufacturing. Historically, the thermoplastic polymer ABS has been one of the most popular 3D printing materials, and was one of the first materials to be used in industrial applications. Indeed, ABS provides high impact resistance, and is also easy to use. On the 26th of May, 3Dnatives was joined by Kimya and MakerBot to discuss the benefits of using composite ABS filaments for industrial 3D printing applications.

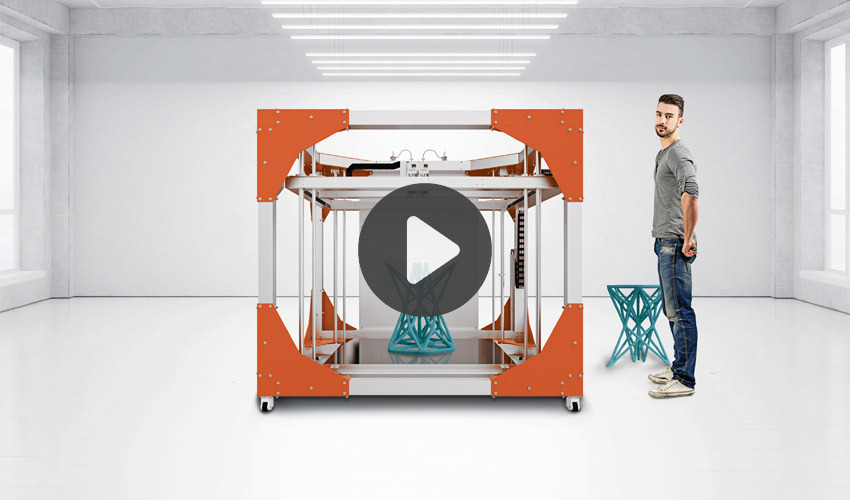

Top 2: Design rules for large format 3D printing

As you know, additive manufacturing involves different design rules than those used in traditional industry. We are talking about topological optimization, lattice structures, part orientation, etc. If design is crucial, it is even more so for large-scale 3D printing. Indeed, designing for large format 3D printing implies being vigilant because a design error can have serious consequences – the part has to be reworked, material is thrown away, etc. The manufacturer BigRep gives us a series of tips to help us design large format industrial parts.

Top 3: A 3D printed dress with sensors

Anouk Wipprecht is a Dutch designer who has relied on additive manufacturing to design various fashion projects. Her latest project is called “Proximity Dress”: it is a 3D printed dress with sensors in order to respect the safety distances related to COVID-19. In concrete terms, the dress stretches – or unfolds – when someone is too close to the person wearing it. The designer explains that she printed different elements of her dress in 3D from resin. A garment you don’t see every day!

Top 4: Making a model of Chicago

In this video, you can follow the making-of of this model of Chicago. The materials manufacturer DSM and the Chicago Architecture Center have created a large 3D map of the city, representing every monument, building, street and detail using 3D resin printers. The DSM teams did the printing while the architectural center’s teams assembled the entire model – a job that took 4 days!

Top 5: 3D printing, the next revolution?

Traditional manufacturing techniques like milling, casting and gluing could soon be replaced by 3D printing – saving enormous amounts of material and energy, whilst also accelerating lead times and encouraging local production. Airbus is already benefiting from the new manufacturing method. Beginning this year, the A350 airliner will fly with printed door locking shafts. Where previously ten parts had to be installed, today that’s down to just one – saving many manufacturing steps. In the following documentary by DW Documentary learn more about how 3D printing is having an impact on our supply chains!

What did you think of these videos? Drop a comment below or on our Facebook and Twitter pages! And don’t forget to sign up to our free weekly Newsletter to keep updated on all the latest news in the 3D industry coming straight to your inbox!