Top 5 Videos: The Velaskello project promotes recycling using 3D printing

In this week’s top five we will cover a universally important topic: recycling. Specifically, we will get familiar with the Velaskello project, by SuperForma, which uses 3D printing with PLA to incorporate more sustainable solutions that reduce humanity’s ecological footprint. Also, we will see how the Nissan company has integrated additive manufacturing into its factory located in Barcelona. Lastly, we will learn just how Nike Air Force 1 has been given a new life with 3D printing. All that, and much more in this weekly video compilation, have a wonderful Sunday!

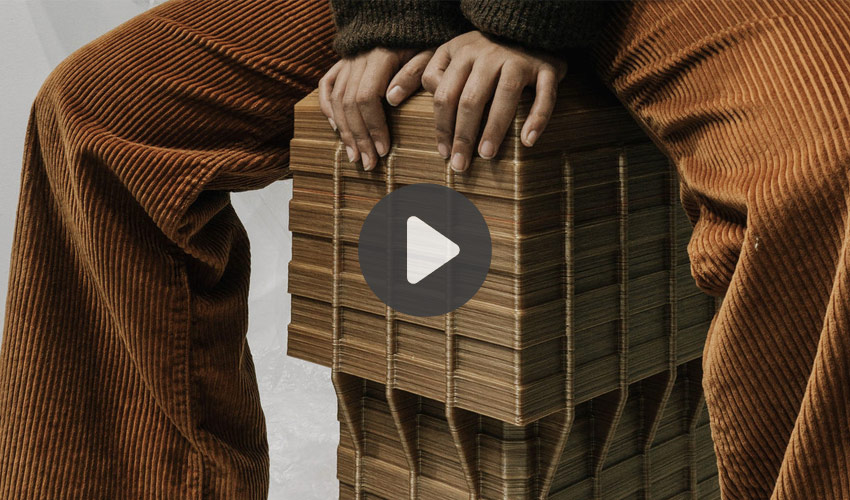

TOP 1: Velaskello 3D Printing

As we’ve seen numerous times, 3D technology and recycling are a winning duo. This has been demonstrated by the Velaskello project, which was born after research on the use of 3D printing with PLA. In fact, in this study, it was deduced that the PLA used in digital manufacturing is biodegradable, but not compostable. For this reason, in many cities, PLA does not find a place within recycling systems. But what if this idea were to be turned around and the material used for other purposes? This is the vision of SuperForma through Velaskello, to reduce the negative impact on the ecological footprint. Find out more below!

TOP 2: Nissan Integrates Additive Manufacturing

A few days ago, we learned in detail how a pioneering team in a factory of the automotive giant Nissan has integrated additive manufacturing technologies in its plant in Barcelona with the goal of creating tools, templates, and accessories. Ultimately, the team plans to develop 3D printed models that are used in all assembly lines to save both manufacturing time and production costs. Furthermore, Nissan has acquired solutions from the Spanish manufacturer BCN3D, dedicated to offering professional machines that would allow the automotive industry to meet its high demands.

TOP 3: AON3D’s New M2 Machines

In this video, the American company Vision Miner offers information about the new M2 solution from Canadian manufacturer AON3D. The video focuses on the production of affordable industrial 3D printers for high-performance thermoplastics. With a build volume of 640 x 450 x 450 mm, the M2 is the largest 3D printer available for less than $100,000. The machine name comes from its predecessor, the M2, which already had many advantages to offer. You can discover what improvements the M2 has in the video below.

TOP 4: 3D Technology in a Nike Air Force 1

In fourth place, we have an initiative that combines 3D printing and footwear. Toolspace co-founder Mikael Beving and with Jenny Halldén have given new life to a pair of old Nike Air Force 1 sneakers, with the help of 3D printing technologies and a PLA filament from the manufacturer Add:North. The shoes are part of the design project called ‘Knock on Wood’ that will be exhibited at the Clarion Hotel Sign, in Stockholm. We let you see the final result of this original project below!

TOP 5: Taking a closer look at AMT and its offerings

Finally, we take a look at AMT who is the world’s first company focused on developing digital technology solutions for post-processing 3D printed parts. Founded in 2017, AMT is dedicated to fully-automated post-processing solutions, a growing necessity in additive manufacturing. In the video below you can learn more about the only company on the market able to fully integrate and fully automate post-processing solutions from start to finish.

What do you think of our selection of videos on 3D printing? Let us know in a comment below or on our Facebook, Twitter and LinkedIn pages! Sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox!