Top 5 videos: when 3D printing meets biomimicry

This week we found the top 5 videos about 3D printing and the way additive manufacturing is changing production. The technology has infiltrated many sectors, from medical to automotive – check our selection of the week to keep up with the innovations! If you enjoy these, you can view even more 3D printing videos on our Youtube channel. Hope you’ll enjoy and have a great Sunday!

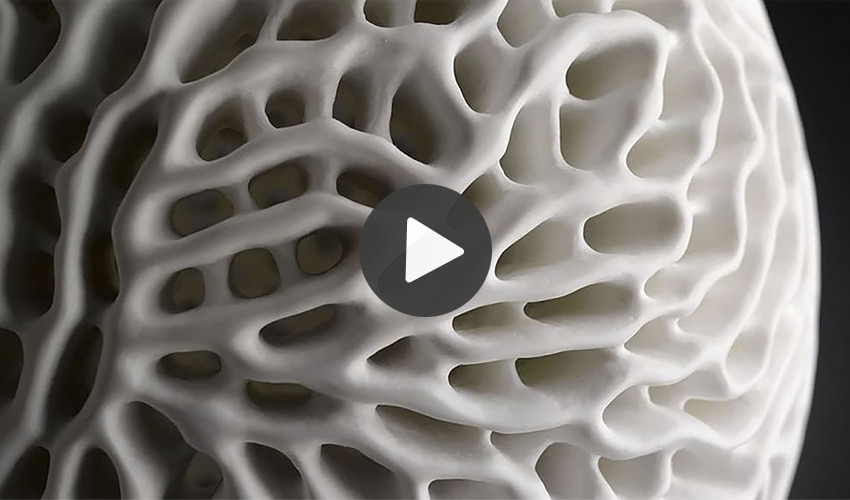

Top 1: When 3D printing meets biomimicry

In the word Biomimicry, bio stands for nature and mimesis means imitation. Biomimicry is a way of learning from nature and incorporating its patterns and solutions into our designs. Biomimicry also corroborates with 3D printing as new materials can be developed and new patterns can be introduced. Find out more about the role of biomimicry in 3D printing in the video below.

Top 2: ICON and NASA aim for the Moon

Who hasn’t dreamt of space travel at least once? Thanks to constant technological advances, what once seemed like a fantasy could soon become a reality. ICON, the U.S. startup specializing in advanced building technologies, announced this week that it has won a government contract, including funding from NASA, to begin research and development of a system that would allow additive construction on the Moon. They launched Project Olympus to further advance space exploration. Learn more about ICON’s ambitious project in the video below.

Top 3: Shaping the future of our mobility

At ETH Zurich, a team of students used Sintratec’s 3D printing technology to design an electric motorcycle as part of their ETH city project. The aim is to promote the mobility of tomorrow by making it more environmentally friendly and sustainable. Therefore, the team created a 3D printed electric motorcycle. Sintratec’s SLS technology allowed the team to reduce not only production time but also costs and the amount of material used. We’ll let you discover the result below.

Top 4: Siemens and Ingersoll for AM

The company Ingersoll, dedicated to the development of manufacturing machines, generally for subtractive processes, has collaborated with Siemens. Together the companies have created a production platform that allows to combine additive manufacturing methods and milling. In fact, it can deposit successive layers of plastic while also allowing machining of the part. Above all, the platform offers high production volume and can print both horizontally and vertically without the support, thus saving time and money.

Top 5: The first 3D printed residential building

The construction sector has changed a lot in recent times, especially thanks to concrete additive manufacturing, which allows to build structures faster and with lower costs. More and more German companies start relying on this technology. In fact, this week they presented the first 3D printed residential structure in the country! It has two floors, 80 square meters each, and was printed with a BOD2 machine from the Danish manufacturer COBOD. The use of AM resulted in reduced construction times, less material used and greater geometric freedom!

What did you think about the videos of this week? Which one is your favorite? Tell us in a comment below or on our Facebook and Twitter pages! And don’t forget to sign up to our free weekly Newsletter to keep updated on all the latest news in the 3D industry coming straight to your inbox!