The National University of Colombia Is Using 3D Printing To Reduce Radiation Therapy Damage

Radiation therapy is a process that some people undergo to cure or relieve symptoms caused by cancer. In the past, radiation therapy significantly damaged parts of the body by focusing radiation exposure on the targeted area of the cancer. Today there is a material called a bolus, equivalent to tissue, which is used to reduce the depth of the maximum dose of the rays. It is a flexible material since it has to adapt to the curvatures of the body. Different types of boluses are used in radiotherapy, depending on factors such as the location of the tumor, the depth of the radiation or the characteristics of the patient themselves. Some examples of materials used are plastics or silicone. However, a new development from the National University of Columbia has introduced a possibly more effective bolus made from 3D printed material.

The most common boluses are made of kerosene, which is a petroleum derivative, explains the National University of Colombia (UNAL). They also point out that these petroleum-derived materials do not adapt well to the patient’s body, generating air pockets, thus affecting dosimetry; the dose of radiation absorbed by the patient’s tissues during the application of the treatment. Although Formlabs and Frontiers in Oncology have experimented with 3D bolus printing in recent years, they have thus far not obtained optimal results. However, Karen Marcela Carrillo Chacón, with a master’s degree in Medical Physics from UNAL, has managed to optimize bolus 3D printing with surprising results.

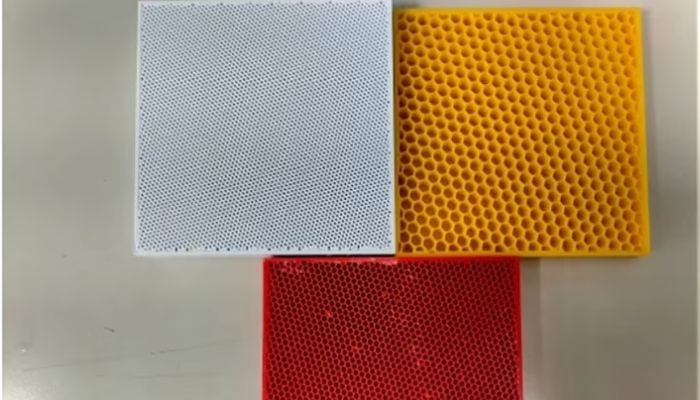

3D printed boluses for radiotherapy treatments

Testing The 3D Printed Bolus: Function and Material

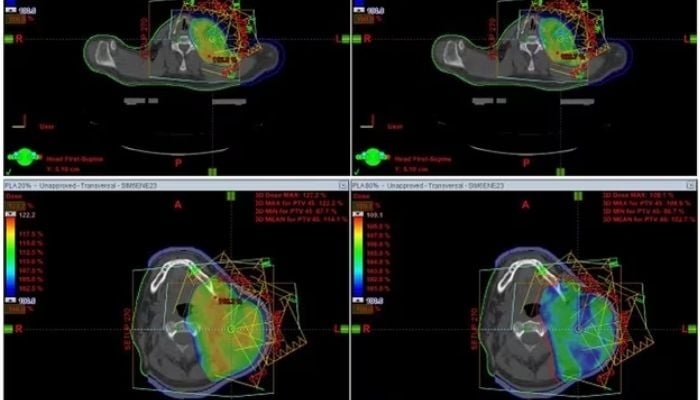

3D bolus printing has made it possible to create customized materials for different patients. These materials adapt to the patient’s body in a way that improves the distribution of radiation, reducing the damage caused to the organs and tissue surrounding the area where the tumor is located. Karen worked on this technology in conjunction with the National Cancer Institute of Colombia (INC). The results obtained were so promising thanks to the materials used, which in this case were ABS and PLA. The National University of Colombia explains that “hundreds of sheets” were printed and tested in a linear accelerator, the device responsible for applying radiation to the patient’s cancer cells.

Karen conducted 3D printing tests using different amounts of material in each sheet, where she observed that the more material used, the fewer air spaces were left in the skin. These materials underwent a series of rigorous radiotherapy tests. They began by using photons, which are used to treat complex tumors. The next test consisted of electrons used to destroy superficial cancer cells. And finally, brachytherapy, which uses the radioactive isotope iridium-192. After the tests, Karen explained the results, “The percentage of impression in which the films are more similar to commercial bolus in radiotherapies should be 60% for the photon technique with ABS material, and 40% for PLA. On the other hand, for the electron technique, the percentage increases to 80 % for both materials and in brachytherapy, 60 % is suggested”.

The Tunja hospital, located in Boyacá, lent its 3D printers to Karen’s project in order to develop her research, despite the fact that in Colombia there are only two hospitals with 3D printers. Karen points out that 3D printing technology has great advantages, such as the ability to adapt to the individual needs of each patient, even in complicated areas where radiotherapy is usually applied, such as the breast or face.

Images of a 3D printed bolus supporting and containing radiation during radiotherapy tests

What do you think of this 3D printed bolus breakthrough? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*All Photo Credits: Karen Carrillo