The Top Glass 3D Printers on the Market

Glass is one of the oldest materials on Earth, worked by humans more than 100,000 years ago. It was used to make tools and weapons, and over time, its applications multiplied. Looking around us today, glass is everywhere and exists in many forms. There are also many different variations that offer different properties and characteristics. But if glass is so present in our lives, what about additive manufacturing? Can glass be 3D printed? The answer is yes, but it is a complex material to work with. Indeed, working with glass requires very high melting temperatures (around 1,000°C) and an extremely controlled, precise thermal environment. Despite these constraints, some players have developed glass 3D printers capable of producing all kinds of parts. While some are now commercially available, most remain research projects. Here’s more!

The Maple 4 by Maple Glass Printing

The Maple 4 is a desktop glass 3D printer that combines simplicity with advanced performance. Unlike traditional glass fabrication, which requires extreme heat and specialized equipment, this system makes the process more accessible and efficient. Compact at 736 x 600 x 985 mm and weighing approximately 100 kg, it operates on a standard 220–240V outlet, achieving nozzle temperatures of nearly 1000 °C. It has a 200 × 200 × 300 mm build volume and can manage high flow rate printing. It can also produce detailed glass parts in just under an hour. Its features include one-click printing, automatic mesh bed leveling, and a magnetic print bed, which help to ease use and ensure consistent results.

(Photo Credit: Maple Glass Printing)

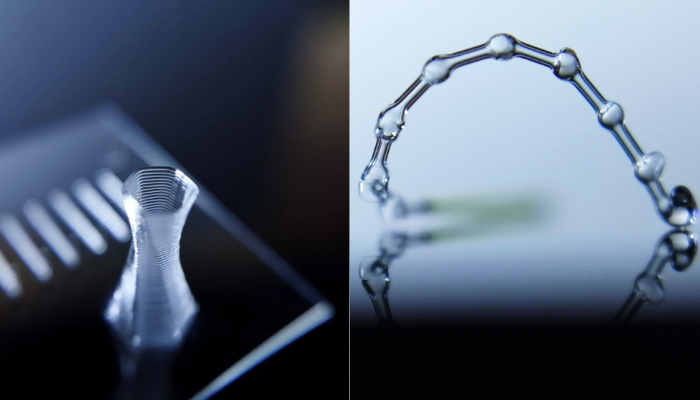

Glass 3D Printer from Nobula

The Nobula Glass 3D Printer introduces Direct Glass Laser Deposition (DGLD), a technology that the company says “makes printing glass as straightforward as printing plastic.” The printer is capable of reaching up to 2200 °C with non-contact laser heating. It is high-precision and energy-effective while eliminating the need for post-processing. The device is around 100 × 40 × 60 cm and weighs just over 50 kg. The system offers a resolution of 100–250 μm and supports infills from 0 to 100 percent. With print speeds ranging from 5 to 200 mm per minute, users can produce free-standing structures with fine detail and great performance. The device is optimized for silica glass and compatible with both Nobula and commercial slicing software. This Glass 3D Printer from Nobula opens the door to complex, high-quality glass components across research, design, and advanced manufacturing applications.

A vase and hollow structure printed using the Nobula Glass 3D Printer with the company’s unique patent-pending glass filament. (Photo Credit: Nobula)

MIT’s Glass 3D Printer

The American research institute MIT was undoubtedly one of the first to look into developing a glass 3D printer. The first tests began in 2015, when a group of researchers led by Neri Oxman presented a process capable of extruding molten glass layer by layer. A few years later, the first version of their machine evolved into the G3DP2. This printing solution can continuously deposit 30 kilograms of molten glass, integrating a thermal control system to ensure proper glass formation and quality. The machine can thus produce transparent glass parts, regardless of the intended application. Today, the G3DP2 is not directly available for purchase, but the solution is currently used daily by the studio Evenline, where you can even order glass parts directly through their website.

The first iteration of the G3DP (Photo Credit: MIT/Oxman)

3D Printing Glass with Glassomer

Glassomer is a German company that has specialized in the additive manufacturing of glass. It does not currently market machines per se, but instead offers its expertise in 3D printing glass parts, specifically prototypes, regardless of their shape. For example, it can print different designs of your future bottle, or decorative objects and jewelry. Glassomer is able to provide this type of service because it has developed a process to create the raw material itself. This consists of a composite material, liquid for 3D printing and solid for injection, made from silica glass powder and an organic binder. This is the material used in additive manufacturing, enabling the production of transparent glass parts.

An example of a 3D printed bottle from the printer. (Photo Credit: Glassomer)

Low-Temperature Additive Manufacturing of Glass

One line of research worth highlighting is that of MIT’s Lincoln Laboratory on low-temperature additive manufacturing of glass. Their approach is quite innovative, since glass is almost always processed at very high temperatures. However, they did not apply any similar technique. So, how did they manage it? The process begins at room temperature: using direct ink writing, the object is formed layer by layer. It is then cured in a mineral oil bath heated to just 250 °C, compared to the >1000 °C typically required with conventional methods. Once the thermal treatment is complete, the piece is rinsed with an inorganic solvent to remove residual mineral oil and it is ready. As for the material compatible with this process, it is a multimaterial ink, also developed by Lincoln Laboratory, composed of a silicate solution and nanoparticles of other inorganic compounds. The study is ongoing, but results show that the technique could enable easier 3D printing of glass devices such as microfluidic systems, optical lenses, and high-temperature electronic components.

Glass cups printed using the low-temperature process. (Photo Credit: Lincoln Laboratory)

3D Printing Glass for Microstructures

Researchers at the University of California, Berkeley, in collaboration with the University of Freiburg (Germany), have developed a technique to 3D print glass microstructures. The technique is based on a process developed years ago, computed axial lithography (CAL), but now they have managed to print with finer details, at the microscale, and in glass. This new process has been named micro-CAL. Unlike traditional methods, the process does not print layer by layer but instead prints the entire object simultaneously. A laser is used to project light patterns into a special resin material that contains glass nanoparticles surrounded by a light-sensitive binder. The light solidifies the binder, and then the object is heated to remove the excess binder and fuse the particles together, resulting in a solid piece of pure glass. Why print microstructures in glass? The researchers point to several applications: microscopic optical components, virtual reality glasses, advanced microscopes, and other scientific instruments.

A 3D printed trifurcated microtubule model next to a mosquito. (Photo Credit: Adam Lau / Berkeley Engineering)

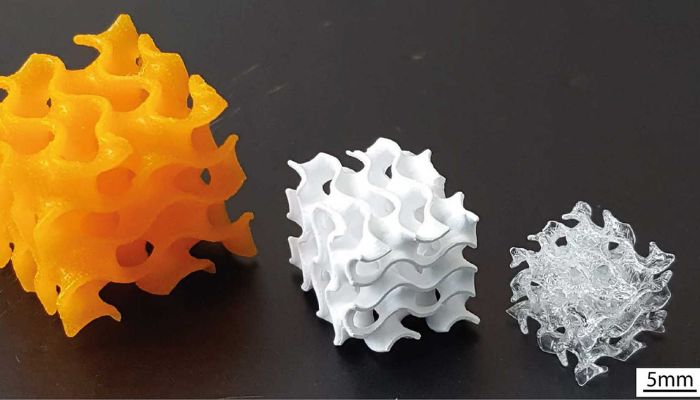

ETH Zurich’s 3D Printed Glass through SLA

Researchers from ETH Zurich set out in 2019 to demonstrate that complex glass objects could be 3D printed, and they succeeded, later applying for a patent. Using stereolithography with a resin that combined plastic and organic molecules bonded to glass precursors, the team was able to create intricate, highly porous glass structures. Specifically, they employed digital light processing (DLP), discovering that the pore size of an object could be tuned by adjusting the intensity of the light. Once the resin was cured, the printed pieces were fired in two stages: first at 600˚C to burn away the polymer framework, and then at around 1000˚C to densify the ceramic into glass. While this process caused the objects to shrink considerably, the final product was transparent and hard, similar to window glass.

The blank (left) is fired at 600 degrees to remove the plastic framework. The object is fired again and becomes glass (right). (Photo Credit: Group for Complex Materials / ETH Zurich)

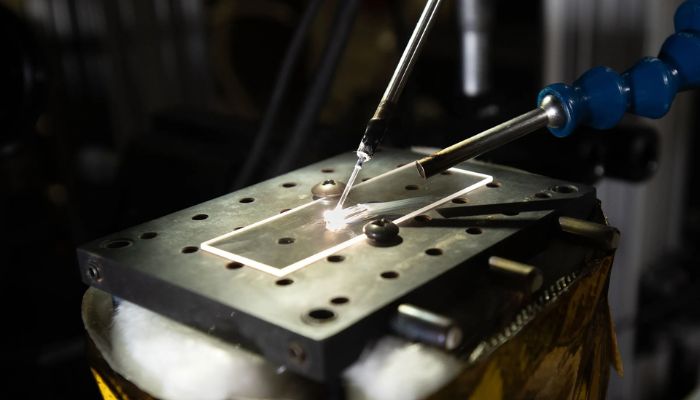

University of Notre Dame’s Deposition-Based Glass 3D Printing

Another innovative approach to glass 3D printing was developed by researchers at the University of Notre Dame. Their method uses a carbon dioxide laser to heat the surface of a glass rod, which then melts onto a fused quartz substrate mounted on a 4-axis CNC platform. The combination of substrate interaction, pressure from the unheated portion of the filament, gravity, and surface tension allows the glass to form in a controlled way. Using this technique, the team was able to create both 2D patterns and free-standing 3D spiral structures. The work advanced further when Ed Kinzel, who led the Notre Dame study, partnered with colleagues from the Monterrey Institute of Technology and Higher Education in Mexico. Together, they moved from producing hollow shapes to achieving dense, fully transparent 3D solids. Although precision remains a challenge, the researchers are optimistic that with further refinements, even higher performance can be reached.

The University of Notre Dame developed the 3D printing method. (Photo Credit: Wes Evard / University of Notre Dame)

What are your thoughts on these printers? Have you ever attempted 3D printing glass? Let us know in a comment below or on our LinkedIn or Facebook pages! Plus, don’t forget to sign up for our free weekly Newsletter to get the latest 3D printing news straight to your inbox. You can also find all our videos on our YouTube channel.