The Best Generative Design Software for 3D Printing in 2023

Designing is the first step in any 3D printing process and plays a critical role in ensuring that the final part will come out correctly. However, this stage can be difficult even for those accustomed to design for additive manufacturing (DfAM). This is where software comes in. We have already told you about the benefits of topological optimization software, but another increasingly important tool is generative design. Though often lumped together with topological optimization software (as well as usually available in tools offering the former!), generative design differs as it actually generates outputs based on specified parameters or constraints that have been put into the software. Thus, rather than optimizing what was already created, it can imagine an entirely new structure that may not have been considered before. To give you a better idea of the various tools currently available, you will find a list below (in alphabetical order based on the name of the product) of the available generative design software on the market, including those designed only for generative design and others where it is included as an extension.

Ansys Discovery

The Ansys Discovery software has been developed to ensure enhanced efficiency and address critical questions during the early stages of conceptualization. By integrating the Ansys Mechanical and Ansys Fluent tools, this software enables interactive 3D modeling. Its primary purpose is to facilitate the design, exploration, and validation of products. Users have access to three modes: the Model mode for creating and editing concepts, the Explore mode for real-time simulations, and the Refine mode for concept validation. All relevant information is easily accessible to the participants.This powerful tool allows for multiphysics simulations, real-time simulations, and high-fidelity simulations of the created concepts. Additionally, it offers the capability to evaluate and optimize the mechanical, thermal, and electromagnetic properties of the designs during the analysis phase. The software emphasizes innovation and user-friendliness, fostering collaboration among stakeholders and ultimately leading to increased productivity. By conducting numerous simulations, it significantly reduces the need for prototypes and tests, saving time and resources in advance.

Ansys Discovery enables the analysis of concepts in terms of their thermal properties. (Photo credits: Ansys)

CATIA Generative Design Engineering – Dassault Systemes

CATIA software, developed by Dassault Systèmes, is renowned for its capabilities in design, engineering, systems engineering, and construction. It serves as a cornerstone of the Industry Solution Experiences offered by the company. The primary objective of CATIA is to enhance product conception for businesses across all levels and provide them with a competitive edge in the market. CATIA excels in designing unconventional and innovative concepts, offering unparalleled 3D modeling and simulation functionalities. Leveraging the intuitive 3DEXPERIENCE® platform, users can refine, analyze, and compare their created concepts with other models. Whether for additive or traditional manufacturing processes, CATIA accommodates various steps involved. The 3DEXPERIENCE platform fosters collaboration among designers, simulation teams, and manufacturing engineers by prioritizing user-friendliness, accessibility, and intuitive operation. This ensures a seamless and efficient workflow, allowing stakeholders to work together effortlessly in achieving their design goals.

Creo Generative Design – PTC

Creo, provided by PTC, is a software that offers CAD, PLM, IoT, and AR solutions, working together to establish a digital thread that spans the entire product lifecycle and enhances data continuity for businesses. Within Creo’s traditional CAD software, there are two extensions specifically for generative design: Creo Generative Topology Optimization Extension (GTO) and Generative Design Extension (GDX). GTO combines generative design and topology optimization, enabling users to quickly explore innovative design options and reduce development time and costs, all within the Creo design environment. The cloud-based GDX extension allows for the simultaneous creation of multiple projects, using different materials and production scenarios. It highlights the best options, making it easier for users to review and evaluate designs effectively.

CogniCad – ParaMatters/Carbon

CogniCAD is a cloud-based platform developed by ParaMatters, a leading provider of generative design software for additive manufacturing. Recently, it was acquired by the US company Carbon and enriched with additional functionalities, including topology optimization. By seamlessly integrating into the manufacturing process, this software combines generative design with additive manufacturing, tailoring it to the specific requirements of individual products. CogniCAD streamlines the design, simulation, and manufacturing workflow by automating topology optimization, finite element analysis, and computational geometry. This eliminates the need for manual adjustments or reconstructions. Designs generated with CogniCAD not only meet all design requirements but also require minimal manufacturing preparation time, typically ranging from minutes to a few hours. Leveraging a range of generative design tools, the software produces lightweight components with enhanced mechanical properties, effectively reducing post-processing requirements. In summary, CogniCAD empowers users with a comprehensive and efficient solution for generative design, simulation, and manufacturing, delivering optimized product designs and significant time savings throughout the process.

ColdStream by Diabatix

Diabatix is a Belgian technology company dedicated to assisting businesses in enhancing product cooling. To achieve this, they have turned to generative design and 3D printing to create innovative thermal heat sinks. Their latest offering, ColdStream, is an engineering platform available on the cloud that supports the entire refrigeration design process, from thermal analysis to thermal design. This powerful software is designed to guide users through each phase of the cooling design process, from optimizing initial concepts to conducting virtual tests and detailed analyses. ColdStream provides a wide range of features and functionalities to streamline project management. The software can analyze heat flow performance within a given system, enabling it to generate customized designs or incorporate standard components such as fins, channels, and other heat dissipators. By improving temperature transfer efficiency and minimizing the risk of future overheating, engineers can develop cooling solutions tailored to the precise conditions, constraints, and temperature requirements of their products. This not only maximizes performance but also minimizes overall costs. With Diabatix’s cutting-edge technology and ColdStream’s comprehensive capabilities, businesses can create efficient cooling solutions that optimize product performance while maintaining cost-effectiveness.

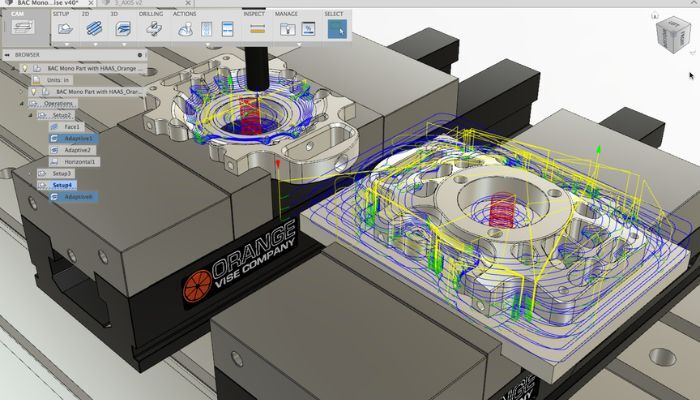

Fusion 360 Generative Design – Autodesk

Fusion 360 is a cloud-based 3D modeling software developed by Autodesk that combines CAD, CAM, and CAE tools into a unified platform. It is designed to facilitate product development, particularly in the field of additive manufacturing. Fusion 360 offers a range of features including sketching, parametric modeling, direct modeling, freeform modeling, surface modeling, sheet metal, mesh modeling, assemblies, and PCB design integrations. It supports various file formats for 3D printing, making it suitable for sending models to a 3D printer. The software also emphasizes collaboration and allows teams and external stakeholders to work together in real-time on projects. Fusion 360 includes generative design tools that propose manufacturing outcomes based on defined specifications, enabling weight reduction, improved performance, and part consolidation. It also provides simulation tools to assess real-life applications and reduce prototyping costs. While some users find certain tools advanced and others, like organic modeling, less developed, Fusion 360 is considered relatively user-friendly, with ample online resources for learning. Autodesk offers a free trial of Fusion 360 for up to 30 days to explore its capabilities.

Photo credits: AutoDesk

MSC APEX Generative Design – Hexagon

MSC Apex Generative Design is advanced software developed by Swedish company Hexagon, specifically designed to facilitate generative design processes. Notable for its user-friendly interface, it offers an automated workflow within a comprehensive CAE environment. Users can effortlessly import parts, carry out the design process, and seamlessly export designs for manufacturing, resulting in an efficient and streamlined workflow. The software’s primary focus is on creating intricate and complex structures that are only feasible through additive manufacturing techniques. These optimized designs feature smooth transitions between different structural elements and incorporate self-supporting structures, eliminating the need for additional support materials during the printing process. Unlike traditional methods that rely on density fields, MSC Apex Generative Design using a meticulously generated mesh with well-defined elements. This unique approach enables the algorithm to directly assess stress factors and generate geometries that surpass conventional human imagination.

Photo credits: Hexagon

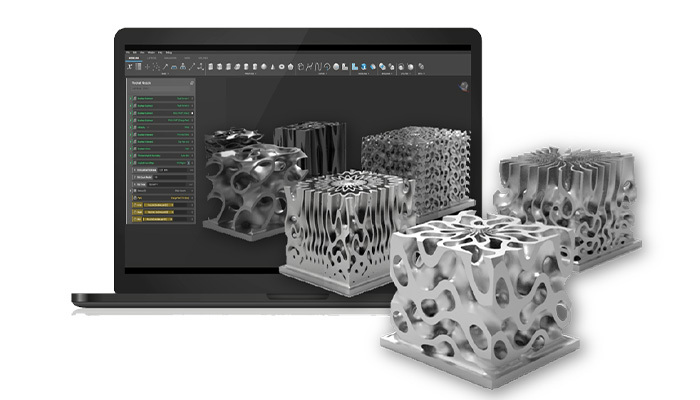

NTop – NTopology

NTopology is a company that has developed nTop, a specialized engineering software specifically designed for the next generation of technical design tools in additive manufacturing. Its primary purpose is to enable users to create innovative solutions that were previously considered impractical or unattainable. The software caters to industries such as aerospace, defense, automotive, medical, and energy, offering advanced capabilities in Generative Design. In essence, nTop provides a comprehensive set of computational tools that allow users to quickly generate and evaluate geometry based on their defined design requirements and constraints. This includes various modeling operations and the optimization of print bed configurations. Moreover, nTop offers the flexibility to develop custom generative algorithms or seamlessly integrate with external design and analysis solutions, enabling users to further refine, automate, and optimize their results and processes.

Photo credits: nTopology

NX – Siemens

The NX software, developed by Siemens, caters to various manufacturing applications, including additive manufacturing, CNC machining, robotics, and quality control. It offers a range of advantages for businesses. One key feature is the promise of up to 50% shorter product development cycles, achieved through reduced prototype iterations and post-processing requirements. Siemens also provides Simcenter HEEDS, a generative design solution that seamlessly integrates NX CAD geometry with Simcenter CAE simulation, enabling the creation of optimized designs. These optimized design options can then be realized through 3D printing. NX software includes tools for efficient build preparation, such as support structure generation and effective part placement and alignment. Furthermore, NX facilitates part simulation and seamlessly connects with a variety of printing technologies, including powder bed, FDM, multimaterial, and multi-axis systems. This comprehensive suite of features empowers manufacturers to streamline their processes, achieve optimal design outcomes, and leverage the benefits of additive manufacturing.

Photo credits: Siemens

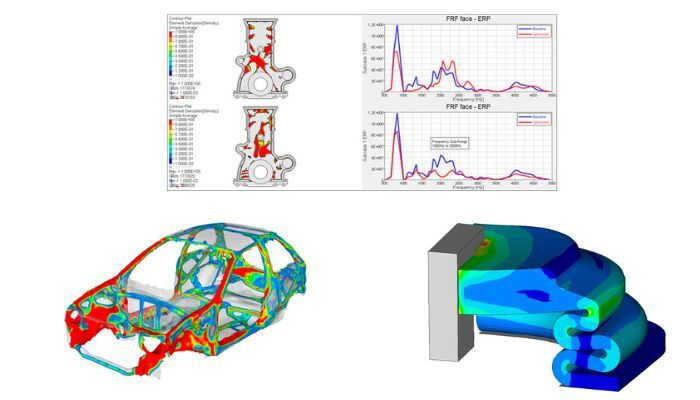

OptiStruct – Altair®

OptiStruct, developed by Altair, is a structural analysis-based optimization solution. With a history of over two decades, OptiStruct is a software solution that combines structural analysis and optimization, allowing for the optimization of designed parts. It provides support for both linear and nonlinear analyses, considering the relationships between forces and displacements, whether they are linear or nonlinear. Nonlinear relationships can arise from unique part geometries, material properties, or contact interactions. OptiStruct builds upon the foundations of NASTRAN, a software originally developed by NASA in the late 1960s, and incorporates internally developed algorithms. During the process of part design or optimization, OptiStruct takes into account static mechanics, dynamic analytics, vibrations, acoustics, fatigue (the damage caused to a part over time due to applied forces), heat transfer, and multi-physics simulation (simulating different aspects of a physical system and their interactions simultaneously, such as both physical stress and temperature distribution). While OptiStruct is renowned for its topological optimization capabilities, it offers much more than that. The software provides various other methods for structural optimization and a wide range of solutions tailored to essential manufacturing constraints. It caters to traditional production processes, composite materials, and additive manufacturing, ensuring a comprehensive set of tools for designers and engineers.

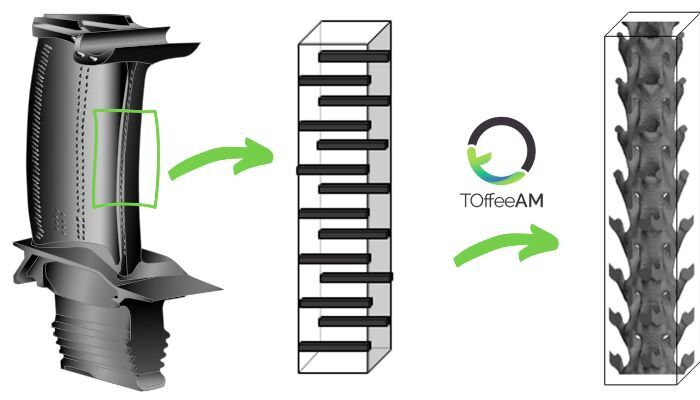

TOffeeAM

TOffeeAM is a spinout company from Imperial College, specializing in additive manufacturing. Their software, TOffee, revolutionizes design by enabling complex and efficient 3D printed parts and systems. This innovative approach, known as Multiphysics Generative Design, combines multiple physical problems with manufacturing constraints. By using additive manufacturing, companies benefit from the ability to print from digital prototypes, enjoy design flexibility, and reduce logistical, material, and energy waste. With worldwide recognition and support from prestigious institutions, TOffeeAM’s expertise extends to various industries such as aerospace, automotive, and energy, where they have successfully optimized components like coolant systems, valves, combustion chambers, power system cooling, fuel cells, vented brakes, pipes, mixers, and cogeneration systems. Their contributions have led to significant efficiency gains, such as achieving up to a 30% increase in coolant system efficiency for aerospace applications and the streamlining of complex systems into a single component using generative design.

Photo credits: TOffeeAM

Transcend Design Generator

Transcend Design Generator, developed by the New Jersey-based company Transcend, is a cutting-edge generative design software. With its intuitive and user-friendly interface, it delivers precise results. This powerful platform empowers professionals to efficiently generate preliminary designs for complex infrastructure projects, including those in the energy sector, reducing design time by up to 90%. By streamlining processes and minimizing risks, this software revolutionizes the design workflow. By harnessing hundreds of thousands of decision algorithms, Transcend Design Generator combines simulations and dynamics to optimize and validate designs. It ensures the validity of all inputs and produces accurate design outputs. Leveraging its automated system, the software taps into global databases to meticulously select and size each component required for the installation. The result is a comprehensive 3D Building Information Modeling (BIM) model that serves as a solid foundation for cost calculations and further detailed design development.

What do you think about the top generative design softwares of 2023? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.