The Top Biomimicry Projects Using 3D Printing

Biomimicry is defined by Cambridge as “the practice of making technological and industrial design copy natural processes.” Although it may seem counterproductive to bring technological advancements back to the natural world, this practice is driven by the fact that increasingly engineers and scientists are finding that, in many instances, the way that nature has been doing it, especially in terms of design, is best. Furthermore, with the rise of 3D printing technologies, these complex designs are suddenly possible in a way that they have not been with subtractive technologies. As such, in the following non-comprehensive list, we looked at some of the most exciting projects combining 3D printing with biomimicry in no particular order. To better understand how additive manufacturing is helping us to exemplify these optimized patterns.

Earth Moc: Innovation Through Biomimicry

3D printed shoes are no longer a novelty; even major brands like Adidas, New Balance, and Nike are turning to additive manufacturing to create incredible footwear. But that does not mean that innovation is done. In addition to using 3D printing, some are also turning to biomimicry to make even more optimized solutions, such as the case with Earth Moc. Designed by Daniel Shirley as part of Sintratec’s 3D Printing Shoe Design Contest in 2022, the shoe is meant to be reminiscent of intertwining roots and vines to maximize comfort and flexibility. He hopes the TPE-made, light-recovery shoe could be used for relief after hiking or light exercise.

Aguahoja Pavilion

Situated in San Francisco, the AguaHoja Pavilion stands at a height of 5 meters and features an intricate “Totem” structure. This architectural marvel emerged from a collaboration between Neri Oxman, The Mediated Matter Group, and Stratasys, culminating in its impressive realization. Inspired by nature, the design encompasses a series of artifacts predominantly crafted from organic materials shaped by water. The pavilion is supported by a framework additively manufactured using the Stratasys F900 3D printer, ensuring the cohesion of each individual component. Additionally, the project includes an architectural proposal for an environmentally compliant melamine glass structure.

Combining Fashion, Technology, and Nature

U.S. designer Zac Posen significantly impacted the 2016 Met Gala with his 3D printed designs. He collaborated with GE Additive and Protolabs to create dresses, bodices, and accessories for some of the gala’s stars using additive manufacturing. For the clothing worn by Jourdan Dunn, Posen drew inspiration from the shape of a rose, designing a structure composed of 21 petals printed in resin. Each petal measured approximately 50 cm and weighed about half a kilo. Actress Nina Dobrev wore a translucent 3D printed bodice using an SLA solution to evoke the glassy effect of liquid water in motion. It took over 200 hours to manufacture the parts at the Protolabs facility in Germany.

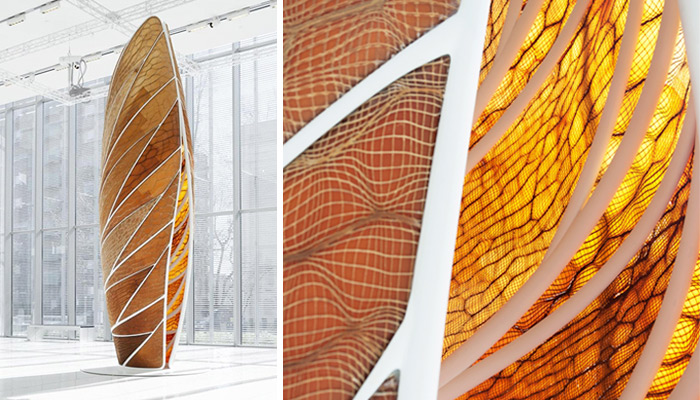

The Tower of Life by Built by Associative Data

The Tower of Life, designed and proposed by Built by Associative Data, is an architectural project in Dakar, Senegal, designed to incorporate ecological efficiency with traditional African design. This structure leverages advanced 3D printing technology, employing a biodegradable, locally sourced clay membrane to reduce environmental impact and construction costs by limiting the need for transported materials. Inspired by biomimicry, the Tower of Life functions as an energy-positive system, efficiently managing resources, water, and air while maintaining a microclimate with minimal emissions. Its design also integrates additional sustainable practices, featuring a structure that mimics natural forms and operates as a closed-loop system, respecting local ecological conditions while contributing to the city’s sustainable development. The company envisions the structure to become an architectural icon in Africa, demonstrating how innovative design and technology can intersect with cultural heritage to create a self-sustaining, ecologically responsible future.

Helical Tubes Inspired by Shark Intestines

Inspired by the spiral-shaped design of shark intestines, which slow food movement and direct it downward using gravity and peristalsis, researchers at the University of Washington have created simplified biomimetic models using 3D printing technology. By developing soft, flexible structures that mimic these intestines, the project aims to understand how their unique design facilitates one-directional fluid flow, potentially leading to faster flow rates in advanced fluid control systems. This biomimicry approach focuses on how the radius and thickness of 3D printed helical tubes impact fluid dynamics, providing insights into the interaction between membranes and flow. As research continues, the team reports that this project could have significant applications in soft robotics, medical and microfluidic devices, and industrial piping.

Helmets with Lattice Structures for Enhanced Safety

3D printing enables the creation of lattice structures directly inspired by nature, and in this particular case, resembling honeycombs. These designs are highly efficient, placing material only where needed, thereby optimizing the weight of the final part. This innovation is particularly valuable in the sports industry, especially for protective equipment. Through 3D printing and biomimicry, some companies have developed bike helmets that are lighter, stronger, more comfortable, and personalized. For instance, KAV Sports and HEXR have used additive manufacturing to design helmets that absorb shocks more effectively, reportedly making them 26% safer than traditional helmets. In American football, Vicis Enhanced has equipped its helmets with 3D printed, honeycomb-inspired pads, which are said to reduce the force of impact by up to 7% when a player’s head contacts the ground.

The HEXR lattice structure helmet (Photo Credits: HEXR)

3D Printed Tiles from Volvo

Moving to Australia for our next example of biomimicry, the coastline of Sydney Harbour is fortified with seawalls covering 50% of its expanse to shield against waves and tides. However, these barriers disrupt marine habitats, compelling species to seek alternative environments. To restore ecological balance along the coast, Swedish car manufacturer Volvo initiated a conservation project in partnership with Reef Design Lab, the Sydney Institute of Marine Science (SIMS), and the North Sydney City Council. Together, they developed and 3D printed tiles that emulate the root structures of local mangrove trees. These tiles, constructed from concrete, were affixed onto existing seawalls. The hollow spaces within the printed structure provided refuge for species like oysters, fish, and algae, thereby rejuvenating marine life along the shores.

3D Printed Seed-Dispersing Slippers

The “Rewild the Run” project, spearheaded by British designer Kiki Grammatopoulos, introduces running shoes designed to transport and disperse seeds during running activities. Leveraging the design flexibility offered by 3D printing, the creator crafted soles equipped with small hooks. As individuals run, these shoes gather plant matter that is subsequently scattered along their running path. The inspiration for these shoes draws from the bison, a species in nature that similarly spreads seeds and creates pathways through its activities. The goal of these shoes is to foster a greener environment amidst the increasing urbanization that has led to the destruction or reduction of natural habitats for many species. Consequently, these shoes are positioned as a positive initiative to restore ecological balance.

(Photo Credits: Ecolosport)

Pinarello Imitates Humpback Whales for Improved Aerodynamics of Racing Bikes

Italian bicycle manufacturer Pinarello stands as a benchmark in cycling, having set the world hour record and providing bikes for the Italian track cycling team defending their team title at the upcoming Olympic Games. Pinarello continually strives to enhance the speed and efficiency of its bikes by leveraging cutting-edge technologies and drawing inspiration from nature’s designs. The frames are crafted through advanced 3D printing processes, while integrated AirFoil sections and AirStream technology contribute significantly to improving bike aerodynamics. Developed in collaboration with the University of Adelaide and NablaFlow, AirStream technology takes cues from humpback whales, specifically their tubercles on fins that aid in easy turning. On Pinarello bikes, these inspirations manifest as AeroNodes on the seat tube and seat post, effectively reducing turbulence and enhancing overall aerodynamic performance.

(Photo Credits: Pinarello)

Mussels as a Model for Adhesives

The blue mussel’s tendency to adhere to boats, much to the dismay of sailors, is attributed to its protein containing the amino acid dihydroxyphenylalanine (DOPA). Researchers at Fraunhofer IAP and IGB have replicated this substance for its adhesive properties, developing an antimicrobial adhesive suitable for medical applications. This adhesive can be applied via 3D printing to bond with bones, facilitating the repair of joint damage. Moreover, it can be applied to existing implants to prolong their lifespan, eliminating the need for surgical replacement interventions.

(Photo Credits: Pixabay)

The Biomic Wall

The Biomic Wall project aims to raise awareness of the current environmental situation and underscore the importance of the relationship between ecology and architecture. It involves a hydroculture wall made from ceramic using 3D printing technology. The prototype was developed as part of a master’s course at the University of Innsbruck in collaboration with Studio cera.LAB and exparch.hochbau. The facade consists of a complex ceramic structure fixed on a metal frame. To achieve this form, 3D extrusion printing was employed with a 4mm nozzle, as conventional manufacturing methods would not have sufficed. The bricks were printed with a resolution of 2mm. The goal of the wall is to integrate modern technology, architecture, and environmental consciousness. Its porous surface promotes plant growth, thereby improving the urban climate. Additionally, the wall responds to its environment by contributing to greening dense urban spaces and reducing noise pollution.

(Photo Credits: cera.LAB)

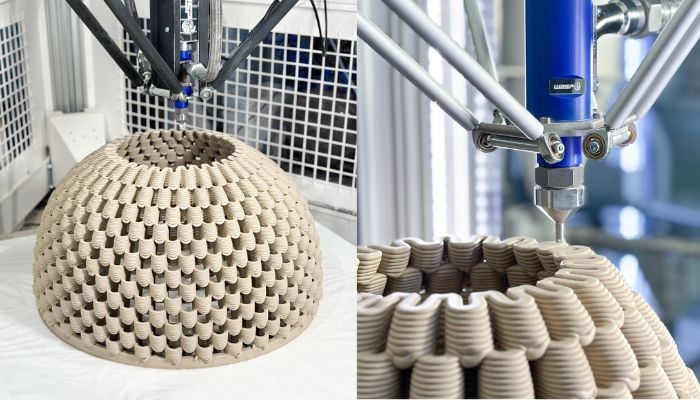

The Lamp Series by Paolo Castelli

In April, the furniture company Paolo Castelli presented a 3D printed hanging lamp inspired by the organic structure of a beehive and its interwoven pattern. This structure is intended to provide calm lighting. The lamp series was produced using 3D ceramic printing in the air and in collaboration with WASP, an Italian 3D printing company specializing in large format and ceramic extrusion technology. As Castelli focused on sustainability in the production of the lamp, natural ceramic materials were used, and a process that minimizes material waste was applied: 3D printing. During development, computer design was first used to create a 3D model based on Castelli’s design. Liquid Deposition Modeling (LDM) technology was then used. Uniquely, the lamp was printed in the air to achieve its sloping shape.

(Photo Credits: WASP)

What do you think of these biomimetic projects using 3D printing? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly newsletter here for the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.