The Top 3D Printing Applications in Ophthalmology

3D printing is becoming increasingly important in medicine and has now also taken on an important role in ophthalmology. One example is 3D-printed glasses, which can be perfectly adapted to the needs and wishes of patients. But it’s not just that. Additive manufacturing opens up new possibilities that improve both the precision and individualization of treatments. And also according to Research And Markets, the market for 3D-printed medical devices is set to grow to $4.9 billion by 2026, with an annual growth rate of 24.5%, illustrating the rapid progress of the technology. That’s why this week, we want to focus our attention on the different applications of 3D printing in ophthalmology. In our ranking, we present various implants, instruments, innovative projects and even contact lenses that have been produced using additive manufacturing. Find out how 3D printing is changing ophthalmology and what benefits it offers for patients and doctors.

Eye Implants and Prosthetics

A Realistic 3D Printed Eye Prosthetic in the UK

In November 2021, history was made for both opthamology and 3D printing when Moorfields Eye Hospital announced that the first British patient had been fitted with a 3D printed eye. Made through a collaboration between the hospital, NHS and UCL researchers, with Fraunhofer and Ocupeye involved with the software, the prosthetic eye was considered to be a true biomimic and a more realistic prosthetic, with real depth to the pupil and clearer definition. It was given to Steve Verze who used it to replace his regular prosthetic, noting that for him it looks fantastic as it was made using digital scans of his other eye, nearly perfectly matching it. An incredible accomplishment!

Steve Verze with his new 3D printed eye prosthetic (photo credits: Moorfields Eye Hospital)

3D Printed Ocular Prostheses From Fraunhofer and OCUPEYE

Researchers at the Fraunhofer Institute for Computer Graphics Research IGD, in collaboration with OCUPEYE Ltd, have developed an AI-based method for 3D printing artificial eyes. This innovative technique aims to meet the demand for artificial eyes as it takes 80 percent less time and can produce a complete prosthesis in just 90 minutes, reducing the workload for ocularists fivefold. The 3D-printed prostheses are modeled using a scan of the functioning eye so that they fit perfectly into the patient’s eye socket and look realistic. The data obtained is then entered into an AI model, which creates the design. Printing is then carried out using the J750 Polyjet multi-material printer and VeroVivid materials. With a resolution of 18 billion droplets per cubic centimeter, the printer enables precise eye implants that realistically and aesthetically match the remaining eye. In the future, the team plans to further improve the method in order to reduce production costs.

Photo Credits: Fraunhofer IGD, Johann Reinhard

VisioPrinTech Offers Personalized, 3D Printed Corneas

Our population is getting older and older and health problems increase with age. These affect not only joints, bones and circulation, but also vision. One well-known problem is corneal deformation, which leads to diseases of the cornea in the eye and restricts vision. Normally, these diseases can be treated surgically by donating corneas. However, donations are scarce and there is a high risk of rejection. For this reason, the Karlsruhe Institute of Technology (KIT) is working with Carl Zeiss Meditec AG and Evonik Healthcare on an innovative solution to improve the treatment of corneal diseases using 3D printing. Their developed VisioPrinTech method is based on the use of a biotint – which consists of the patient’s stem cells and chemically modified collagen fibers – that is printed during an operation using laser-based 3D printing. This method not only avoids the challenge of finding donors and possible rejection, but also offers greater precision and functionality. The 3D-printed cornea helps to restore patients’ vision.

Photo Credits: KIT

Artificial Eyes Thanks to 3D Printing and Manual Work

Nicholas Puls, an ocularist at the Royal Brisbane and Women’s Hospital in Australia, makes artificial eyes for patients who have lost their sight due to cancer or injury. This production is time-consuming, especially as the hospital has to supply around 100 patients with prosthetic eyes every year. The Herston Biofabrication Institute has now investigated how 3D printing could improve this production by conducting evaluation studies with patients. The aim was to assess how the appearance of 3D-printed eyes differs from hand-made eyes. The institute used 3D scans and high-resolution photography for this purpose. By mirroring a photo of the healthy eye, it can be replicated, which is a time-saving process. Nevertheless, 3D technology is not necessary competition for hand-made prostheses, it is expected for both to be combined in the future.

The prosthesis can be made from traditionally manufactured or 3D-printed ocular prostheses (photo credits: ABC News/Chris Gillette)

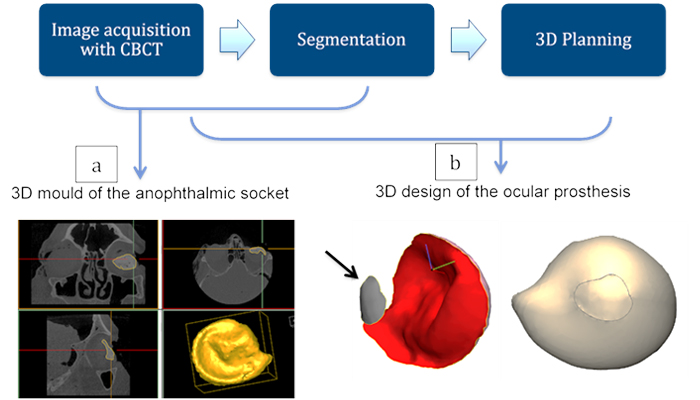

OMFS-IMPATH optimizes ocular prosthesis development

When the absence, loss or decrease in size of an eye occurs, it is essential to have a well-fitted, customized ocular prosthesis to facilitate the patient’s physical and psychosocial rehabilitation. Many patients develop anophthalmic alveolus syndrome, characterized by sagging of the prosthesis and drooping of the eyelids, which leads to low satisfaction with the prosthesis and affects quality of life. OMFS-IMPATH experts have developed an innovative process for designing customized, precision-fit ocular prostheses using 3D scanning, planning and printing technology, exactly replicating the natural eye. This results in a precise anatomical fit, improving the patient’s functional capabilities and physical appearance.

Photo Credits: OMFS-IMPATH

3D Printing Ophthamology Projects, Instruments and Contact Lenses

3D Printed Artificial Eyelids

At the University of Innsbruck, medical students have the opportunity to study and practice on 3D printed artificial eyelids. Artificial eyelids are recreated based on human ones, then analyzed and studied, comparing the mechanical properties of human tissues with those of 3D printed models. This project is of great importance not only for training future doctors and surgeons, but also for providing better patient care. Indeed, surgeons will be able to practice faithful reproduction of a specific patient’s eyelid before entering the operating room.

Photo Credits: Medizinische Universität Innsbruck

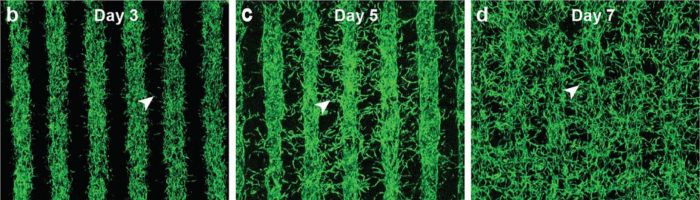

3D Bioprinted Eye Tissue

Scientists at the National Eye Institute (NEI) in the United States have used stem cells from patients and 3D bioprinting to produce eye tissue in order to increase understanding of the mechanisms of diseases that lead to blindness. The research team printed a combination of cells that form the eye’s outer blood-retinal barrier, which supports light-sensitive retinal photoreceptors. The technique provides the possibility of using patient-derived tissue to study degenerative retinal diseases, such as age-related macular degeneration (AMD). To date, in fact, the mechanisms of AMD initiation and progression to advanced stages remain poorly understood due to the lack of physiologically relevant human models. 3D printed tissue analysis and genetic and functional testing showed that the printed tissue appeared and behaved similar to the human outer blood-retinal barrier. The study is therefore moving forward to better understand the origin of these diseases and to specifically test preventive therapies.

Crescita di vasi sanguigni nel tessuto oculare stampato in 3D. Al settimo giorno, i vasi sanguigni riempiono lo spazio tra le file, formando una rete di capillari. (Crediti: Kapil Bharti, Ph.D., NEI)

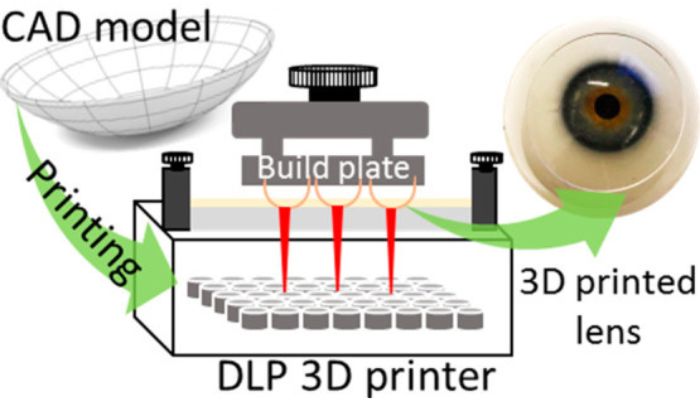

3D Printed Contact Lenses

We’ve already told you about 3D printed glasses, but did you know there are also 3D printed contact lenses? A 2021 project from the Khalifa University of Science and Technology (KUST) sought to make them a reality. By turning to DLP 3D printing and CAD software, they were able to create smart contact lenses, smoothing them afterwards with post-processing done afterward to ensure a smooth surface finish. The best part? They are actually ‘smart’ contact lenses with built-in sensing abilities.

Photo Credits: KUST

The First Eye and Face Transplantation Done With Additive Manufacturing

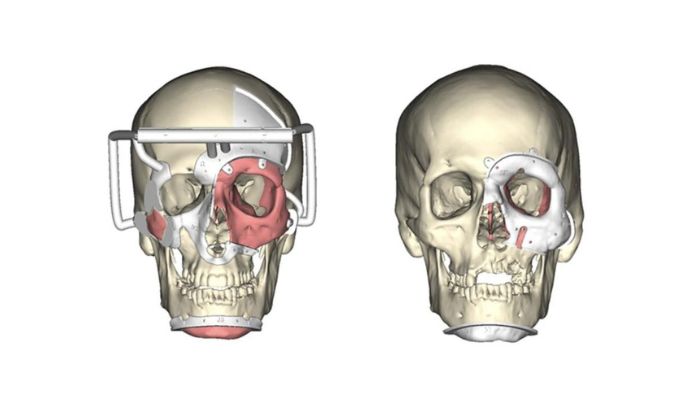

When performing complex operations, it goes without saying that the right surgical instruments are of the utmost importance. Proof of this can be seen in the eye and partial face transplant that an American man received, made possible with the help of planning and the use of additive manufacturing by the Belgian company Materialise. Patient Aaron James suffered a high-voltage accident while working and had to have his left eye and part of his face removed. While he was on the waiting list for a transplant, a medical team from New York University Langone Health Hospital planned the transplant together with clinical engineers from Materialise. The latter played a crucial role in both the planning and the complex surgery. Using computed tomography (CT) scans, they developed a virtual preoperative plan that provided a step-by-step route for the surgical procedure. When the donor was found, Materialise took less than 24 hours to plan the case and designed and 3D printed the necessary instruments. These included custom medical devices, precise bone models and cutting guides adapted to the anatomical structure of the patient and donor. Thanks to the customization and precision of these instruments, risks were reduced and the surgery, the first of its kind, was a complete success.

Custom surgical guides made by Materialise for donor (left) and patient Aaron James (right)(photo credits: Materialise)

Customized Contact Lenses for Cataract Treatment

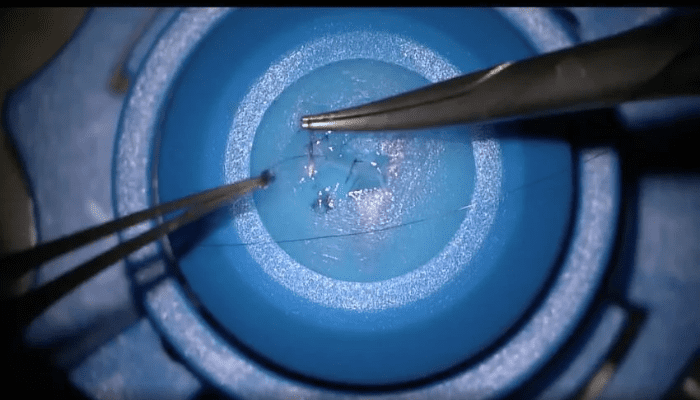

Researchers at the University of East Anglia recently achieved a significant breakthrough in eye device technology. Specifically, they developed a new type of 3D printing resin with which to manufacture eye implants, a crucial element in refractive and cataract surgery. The artificial intraocular lens (IOL) developed can be easily and safely implanted in the capsular bag. This type of printed lens can be customized to the shape of the eye and the visual needs of each patient, which could improve visual correction and comfort. Although these lenses are still under development, the researchers claim that they can also be used to correct refractive defects such as nearsightedness, farsightedness and presbyopia.

Photo Credits: University of East Anglia

Simulation models for eye trauma using 3D printing

At King’s College Hospital in the UK, researchers have developed a simulation model for eye trauma using 3D printing. Designed with Fusion 360 and printed using the Stratasys J850, the model is based on real clinical cases. Evaluated by 14 ophthalmologists and five clinicians, it showed a marked improvement in user confidence in assessment and suturing techniques. 3D printing offers key advantages, such as reduced production times and accelerated prototyping. These models, which can be mass-produced in hospitals, enable doctors to hone their skills more efficiently, while providing an alternative to animal eyes and cadavers for surgical training.

Photo Credits: King’s College Hospital

3D Printed Glasses to Cure Color Blindness

Researchers at Khalifa University have developed 3D-printed glasses that can treat color vision disorders. These glasses, with tinted lenses inserted into frames manufactured by MSLA 3D printing, filter out unwanted wavelengths while allowing the rest of the visible spectrum to pass through. After designing a prototype with SOLIDWORKS, the researchers printed it in ASIGA DentaClear and Gray resin on a Prusa SL1S, with a print time of six seconds per layer and a thickness of 25 microns. According to the team, these 3D-printed frames offer a more customizable and potentially more effective alternative to current commercial eyewear.

Photo Credits: Khalifa University

3D-printed glasses for the treatment of deformed corneas

Dr. Song Hongix, ophthalmologist and researcher at Beijing Tongren Hospital in China, has produced glasses for patients with deformed corneas using 3D printing. These are intended to be particularly suitable for the treatment of keratoconus. This is an eye disease in which vision is impaired by the deformation of the cornea. The lens is designed to be tailor-made and stabilize the patient’s vision. Thanks to 3D printing, the lens can be individually adapted to different corneal shapes. Dr. Hongix was inspired by NASA’s adaptive optics technology, which is used to improve the image quality of telescopes by correcting distortions caused by the Earth’s atmosphere.

Photo Credits: Bejing News

What do you think of the use of 3D printing for ophthalmology? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly newsletter here for the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.