The Role of Construction 3D Printing in Humanitarian Aid

Over the last few decades construction using 3D printing has taken the world by storm. Additive manufacturing has enabled construction companies to build at unprecedented speeds, while minimising waste and labour. Furthermore, with 3D printing, the cost of construction is considerably reduced compared to traditional methods. The technology has also allowed designers to manifest impressive geometrically complex and architecturally interesting designs, which would otherwise be impossible to create. It is therefore no surprise that construction 3D printing is set for massive growth. In fact the global market for construction using 3D printing is expected to reach $114.4 million in 2023.

Its potential profitability has certainly not gone unnoticed, nor has its potential as a force for good. In the course of the last few years, several initiatives have been founded on this concept. Taking advantage of the efficiency, low cost, and sustainability it offers, using 3D printing for construction has become central to many humanitarian focused projects seeking to combat global issues ranging from housing shortages and homelessness to the education crisis.

Construction 3D Printing and the Housing Crisis

According to the State of the Nation’s Housing Report published by Harvard University’s Joint Center for Housing Studies (JCHS), last year the supply of for-sale homes was at its lowest level since at least 1982. A statistic that was only worsened by the pandemic. However, it is not only a shortage of housing that the US faces, but also a persistent shortage of construction workers, which in turn functions to impede the development of new homes. JCHS reported that the average number of job openings for construction workers reached its highest level since at least 2001, at about 321,000 posts that needed to be filled in 2019. Moreover, the US also faces a crisis of affordability. According to Forbes, despite the overall economic turndown, house prices have soared in the last year and Americans across the country are struggling to afford homes.

Community First! Village (Photo Credit: ICON)

Acknowledging these problems, companies like ICON have attempted to find innovative solutions in additive manufacturing technologies. 3D printing not only offers the potential for faster and cheaper construction, but reduces the number of manual laborers. As such, 3D printing is also capable of combating the supply shortage of for-sale homes in the U.S. For Jason Ballard, co-founder of ICON, a 3D printing construction company, the potential of additive manufacturing methods in this field is often overlooked, he expands, “conventional construction methods have many baked-in drawbacks and problems that we’ve taken for granted for so long that we forgot how to imagine any alternative.” This is where 3D printing comes in, Ballard explains, “with 3D printing, you not only have a continuous thermal envelope, high thermal mass, and near zero-waste, but you also have speed, a much broader design palette, next-level resiliency, and the possibility of a quantum leap in affordability. This isn’t 10% better, it’s 10 times better”. Ballard has yet to be proved wrong.

The “quantum leap” in affordability which Ballard describes is no exaggeration. Well-known digital housing marketplace HomeAdvisor, estimates that the cost of building a house (through conventional methods) is on average between $154,273 and $478,200. ICON, however, expects to do so for only $4000, more than one hundred times less than the upper end of HomeAdvisor’s estimates. Rather than capitalizing on this, some companies have used additive manufacturing technologies for humanitarian driven goals.

ICON, for example, has built the Community First! Village. A community of affordable, permanent housing for people who have experienced chronic homelessness. The community consists of a 3D printed 500 sq.-ft. ‘Welcome Center’ and three 400 sq.-ft. homes each 3D printed one at a time for a series of six homes for residents of the community. Each home features a bedroom, a bath, a living room, a bathroom and a porch with sweeping views of the Texas sunsets. According to ICON, its Lavacrete 3D printing technology is capable of building structures able to withstand fire, flooding and other natural disasters which have historically been responsible for destroying homes in many areas of the U.S.

Thus not only are these homes a potential solution for loss of housing after natural disasters but are also in themselves preventative measures against further losses of homes. The Community First! Village is at present the only of its kind in the U.S from nonprofit Mobile Loaves & Fishes. However, its existence alone paves the way for more. In fact, just last year, U.S.-based concrete specialists QUIKRETE and Contour Crafting Corporation announced that they would be partnering in order to build homes for the homeless in L.A.

According to ICON, its Lavacrete 3D printing technology is capable of building structures able to withstand fire, flooding and other natural disasters. (Photo Credit: ICON)

ICON’s operations are not limited to the U.S. alone, nor would it make sense for them to be. As the company itself states there are three critical issues facing global housing at present: First, the average person cannot afford a home; Second, homebuilding is not sustainable, and is both inefficient and wasteful; Finally, there are over one billion people in the world who lack adequate shelter. In 2019 ICON, New Story, and ÉCHALE unveiled the first ever 3D printed community in Tabasco, Mexico. The community contains fifty homes, each of which was granted to a local family previously living in extreme poverty and makeshift, unsafe shelters. Each home is 500 sq ft and was 3D printed using ICON’s robotics, software and advanced material in around 24 hours over the course of several days.

The Role of Construction 3D Printing in Building Schools and Social Infrastructure

Other companies such as Thinking Huts and 14Trees have also put construction 3D printing to humanitarian use by using the technology to build social infrastructure, notably schools, in areas which lack the funding and resources to create them with traditional methods. For 14Trees additive manufacturing was a solution to clear the school backlog of more than 36,000 classrooms in Malawi, which would take more than 70 years using current construction methods. The company comments, “We needed to disrupt the way we build so that every child of today’s generation can go to school. Construction 3D printing is a fantastic opportunity to speed up construction time, reduce the total cost of those buildings while at the same time reducing their carbon footprint. This applies to schools, but also homes and or any social infrastructure (eg. clinics). In Malawi, we showed that it is possible to ‘print’ the walls of a house in less than 12 hours, while reducing the CO2 footprint of that house by up to 70%, compared to conventional methods.”

Brett Hagler, CEO of New Story similarly stated, “We feel it’s our responsibility to challenge traditional methods. Linear methods will never reach the billion + people who need safe homes. Challenging our assumptions, iterating based on data, and taking calculated risks on innovative ideas will allow us to reach more families with the best possible solutions, exponentially faster”. 3D printing is uniquely positioned as a construction method to implement the social infrastructure so needed by so many people all over the world.

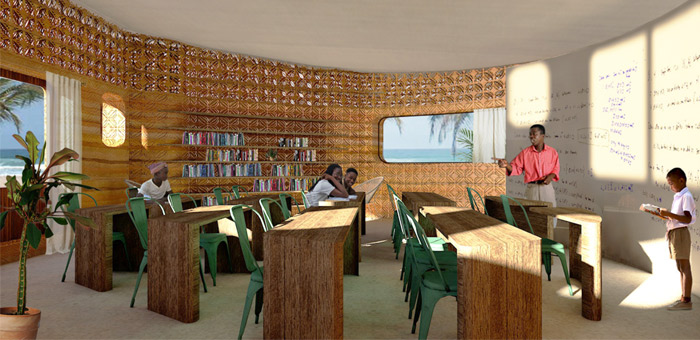

A future classroom (photo credits: Thinking Huts)

What Obstacles Does the Technology Face in this Role?

As a predominantly social, rather than practical issue, the housing crisis cannot be solved by construction alone, additive or otherwise. According to Thinking Huts founder, Maggie Grout, “the greatest challenges are the funding, especially as we aim to apply this high-growth technology to humanitarian goals.” This sentiment is mirrored by Alexandria Lafci, COO of New Story who states, “It took a long time for mobile devices to penetrate Africa because companies focused on more lucrative markets. But look at the impact cell phones had in transforming entire economies and livelihoods on the Continent. Instead of waiting for profit motivation to bring construction advances to the Global South, we are fast tracking innovations like 3D home printing that can be a powerful tool toward ending homelessness”.

Construction 3D printing, while certainly an innovative and efficient method of combating issues relating to lacking social infrastructure and in particular the housing and education crises, first and foremost requires funding and support. This is especially true as current construction additive manufacturing methods are still far from comprehensive, some parts of the school cannot be 3D printed. These parts include the roof, doors and windows, which Thinking Huts intend to make entirely from locally-sourced materials. However with support humanitarian focused construction 3D printing has the potential to completely transform the day to day lives of communities across the globe.

At the moment there are more than 260 million children lacking access to education. This number has only increased since the beginning of the pandemic, which itself has been responsible for the displacement of over a billion children worldwide. When we asked Maggie Grout to describe the company she founded, she explained that Thinking Huts is “a nonprofit that seeks to increase global access to education with innovative, humanitarian-driven technology solutions. We seek to leverage AM to build 3D printed schools with communities where they are needed most”.

Starting with a location in Madagascar, Thinking Huts intends to open their first 3D printed school later this year, and have plans for an additional three schools. The organisation even hopes to one day expand their operation to Zimbabwe, Malawi, Pakistan, India, and South Africa. While the central focus of Thinking Huts’ project is to expand access to education, the company also seeks “to find ways to create a synergy between technology and local communities”. Grout wants to employ local labor and involve the economies of developing communities as well as support technology transfer, echoing Lafci, COO of New Story’s comment on the impact of mobile phones on African economies.

(Photo Credit: 14Trees)

Similarly, when we asked Francois Perrot, Managing Director of 14Trees about the potential role of construction 3D printing in combating the housing and education crises he replied, “Construction 3D printing is a great solution to solve the housing and education crisis. What matters is that all the components needed to print, from the ink used to the teams controlling the robot are found locally, in the countries where we are trying to solve those crises. This is what we have started to do, working with LafargeHolcim countries to produce the 3D printing ink as close as possible to the place where we are printing, creating jobs across the value chain and introducing that technology to the local people. And we have seen extremely positive responses!”.

A second obstacle noted by these organisations is the lack of knowledge and awareness when it comes to construction 3D printing technologies. Grout found “that 3D printing in the construction sector is still relatively unknown. Often, people think that 3D printing is only used on a desktop scale and creates plastic-based objects. For some, it can be difficult to visualize architectural scale 3D printing”. While Perrot commented, “Construction 3D printing is still a nascent technology and there are many challenges we have faced, around the set up of the job site, the preparation of the ink or the design of the house to be easily ‘printable’”.

Working with LafargeHolcim Innovation Center and technology partner COBOD, 14Trees were able to address those challenges individually. According to Perrot, “3D printing requires excellence from the design of the building, to its delivery, and this is this excellence in execution which we are now building and showing with our projects”. Evidently, while there is already a certain degree of success with the technology, there is still a requirement for more research and development of construction 3D printing for it to have a truly successful and widespread impact in humanitarian aid.

(Photo Credit: 14Trees)

Using 3D printing for construction has a massive potential to positively impact the way humanitarian aid is conducted, particularly when it comes to resolving the housing and education crises. The technology also offers significant advantages when it comes to affordability, sustainability, and durability. However, in order to expand the use of construction 3D printing there are some steps that still need to be taken. For the technology to have a truly important impact it requires funding, influence, research and development, and time. Several governmental institutions in the US are increasingly adopting 3D printing, notably the Navy, military, and NASA. This begs the question, what’s stopping Urban Planning from taking up the technology?

What role do you think construction 3D printing will play in humanitarian aid? Let us know in a comment below or on our Facebook, Twitter and LinkedIn pages! Sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox!

*Cover photo credit: ThinkingHuts

We really would like to build some 3D Homes in Hurricane prone areas to see if they will stand up to that kind of storm. BUT we cna’t seem to find a Construction Company to do it. With so much being done, sure wish we could get a Company to work with us.