The Role of 3D Printing in the Manufacturing of Electric Vehicles

Times move forward and society evolves and adapts to new changes. The same phenomenon can be seen with technology, a little more than a decade ago we could not even imagine the technology that we have today at our fingertips. This is reflected in our daily lives, from new inventions such as with “air fryers” or drones with facial tracking to make video reports, to advances in existing technology such as 5G or 3D printing. But, there is one particular advancement that we have become increasingly accustomed to in recent years, and that is electric vehicles (EVs).

These types of cars, motorcycles and even vans are increasingly prominent in our lives. Their low emissions coupled with the cost of filling up a tank are, among other things, attractive for consumers. Indeed, today, a large percentage of cars on the world’s roads are hybrid or electric. And, as we mentioned at the beginning, technology is constantly evolving, and that is why 3D printing is already starting to be implemented in the manufacturing of electric vehicles by a number of brands.

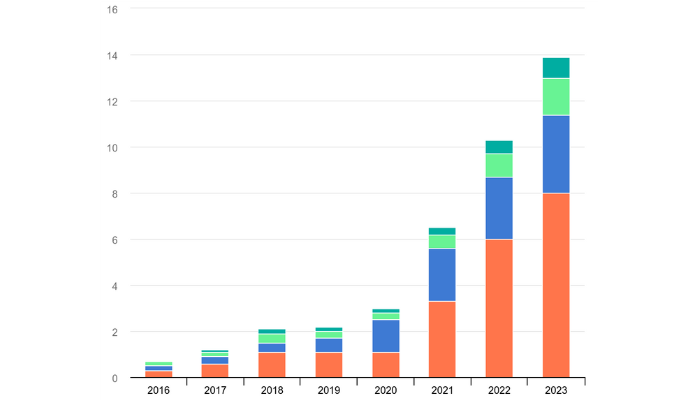

Electric car sales comparing China (orange), Europe (blue) and the USA (neon green) (image credits: IEA)

Why Use Electric Vehicles?

There are several reasons why people decide to purchase an electric vehicle over a gasoline or diesel one. On the one hand, there are those drivers who decide to take action and take responsibility for the environment. Something we all know is that the emissions of an electric vehicle are zero, so this type of driver is able to directly contribute to sustainability efforts. On the other hand, there are those who think about their pocket. An electric car is a large initial investment, but in the long run it is very profitable given the low cost required to use the EV (Electric Vehicle). Finally, there are people who are forced to buy one of these cars for reasons such as restrictions.

Despite the fact that a large number of people believe that what they call the “trendiness” of electric vehicles is just empty words, there are figures that evidence the growing trend and use of this type of cars. For example, according to Statista, the EV market broke records in the United States in 2022 with an estimated 918,500 light electric vehicle sales. This was a significant increase, two and a half times more, than in 2018. This trend can also be seen in the increased popularity of brands like Tesla, or in well known automotive manufacturers like Ford unveiling their own hybrids and EVs over the past few years.

The Start of 3D Printing for Electric Vehicles

3D printing has been part of the automotive sector for some time now. In addition to applications like rapid prototpying, 10 years ago we also started to see the adoption of 3D printing for cars by consumers. It all started when the so-called makers, people who have 3D printers at home and create their own home models, began to design small customization parts for their vehicles. Some of them incorporated small design accessories or even some minor parts of the cars’ structure.

Strati, the first 3D printed electric car (photo credits: Car and Driver)

Still, it was not until 2014 at the International Manufacturing Technology Show in Chicago (IMTS) that a car was first printed in its entirety with a 3D printer. This was Strati, a small two-seater electric vehicle with styling similar to beach buggies produced by Local Motors. This car went unnoticed in most of the global media despite being a first. Unlike other 3D printed cars, Strati had only 49 parts and was printed in less than 48 hours. It also had just under 200 km of range, so despite talk of mass-producing it in 2015, it fell short of being a success.

Years later, in 2018, the car that we know today as XEV YOYO , but at the time was known as LSEV , was introduced. Designed by X Electrical Vehicle (XEV) and manufactured in collaboration with Polymaker, this small vehicle can be printed in just 3h and has only 57 parts. It was launched in 2019, and what was once a small company now has dealers in many parts of the world and sells thousands of vehicles annually.

But if we look back over to about five years ago, we realize that 3D printing in the automotive world was not fully integrated. Until then, some small 3D printed electric vehicles were known, such as the KILO Design or the 4ekolka. These technologies were also used for the restoration of vehicles by Volkswagen or BMW, but we did not even dream of what we have reached today.

The first version of the 4ekolka on display at a motor show

What Are the Compatible 3D Printing Materials and Technologies for Electric Vehicles?

Today, there are many car brands that use 3D printing, whether in small parts for specific electric vehicles (as well as standard ones), or in the production lines themselves. Some examples are Volkswagen, Seat, Toyota or Lexus, but as we have mentioned, there are many more. On the other hand, 3D printers are not the only thing that brands use, another clear example of the use of 3D technologies in the automotive industry are 3D software, 3D scanners and test cars.

Most brands use one or two specific technologies, as is the case of Koenigsegg with FDM and resin or the case of Volkswagen with HP Metal Jet. This means that there is not one type of technology specifically designed for electric vehicles, but depending on the application you want to use, you can make one of one technology or another.

Furthermore, when it comes to materials compatible with EV additive manufacturing, manufacturers were originally limited to the use of plastics. But over time, the range of compatible materials has expanded to include a wide variety. That being said, the most common in the industry are thermoplastic materials such as ABS, nylon or resins.

Most of the parts printed on the above materials are non-critical parts for the vehicle. This means that they do not influence the operation or handling of the vehicle. But, it is possible to 3D print safety critical parts for electric vehicles. In fact, there are companies that are already doing so. These parts, instead of being printed using polymers, are usually printed with metals and alloys. Among these, the most commonly used are titanium and aluminum alloys.

Applications and Uses

Some manufacturers have realized that 3D printed parts are not only faster to produce and less expensive than traditional methods, but they are also just as durable. These printed parts are being subjected to tough tests to learn their limits in order to incorporate them into vehicle production. Whether the parts are printed in metals, plastics or ceramics, they all have to undergo rigorous testing.

Initially, most companies were hesitant to introduce parts created by a 3D printer into their vehicles. With the passage of time, the solidity, robustness and durability of these parts has become evident. In fact, today, there are already many brands that are introducing parts created with these technologies in their cars. Brands such as Volkswagen have up to 13 different car models that incorporate 3D printed parts, whether in metal or plastic. In fact, according to Dr. Stefan Leest, Volkswagen’s Chief Technology Officer, “3D printed parts are as strong as parts manufactured by traditional methods.”

3D printed metal water connectors for Audi’s W12 engine (photo credits: Volkswagen Group)

Examples of these applications include vehicle trim such as dashboards, seat frames, control panels, air vents and cooling ducts, lighting fixtures, covers and console accessories. In addition, crucial vehicle parts such as mounting brackets, housings, double wishbone suspensions and brake components are also beginning to be 3D printed.

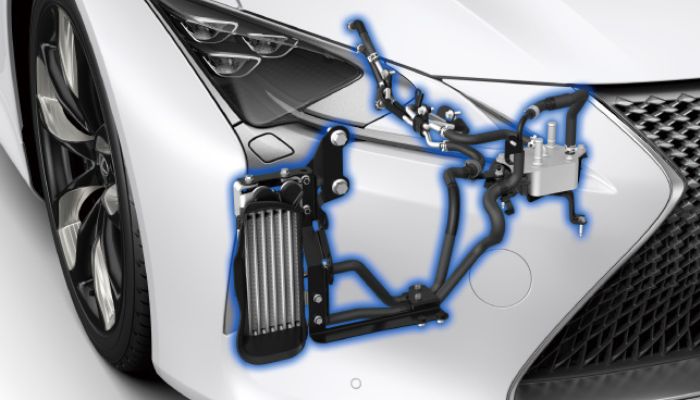

A clear example comes from LEXUS, when at the end of 2023, it announced that in its new version of the LEXUS LC500 sports car, 3D printing would be used to manufacture the AT oil cooler ducts. Initially, doubts were raised about the project for this hybrid supercar. In fact, Tomohiro Ohno, LEXUS body designer, specified, “The two main issues were whether the cost would be feasible, considering low batch production, and how to determine the quality of the parts made with 3D printers.” Finally, after rigorous testing, the project was approved, and in 2024 we will see the LEXUS LC500 on the road with 3D printed parts.

AT oil radiator ducts (photo credits: Solize and LEXUS)

Another scenario in which we have seen 3D printing reflected in electric or hybrid cars is related to the famous hypercar brand Koenigsegg. This brand uses FDM and resin 3D printers in its vehicles to manufacture thousands of parts. All with the help of 3DPrinterOS software. Christian von Koenigsegg, creator and director of the brand, specified in The Quail during Monterey Car Week that they manufacture their own resin, but that its sale is not open to the public. He added: “We’re printing housings for electronic controllers, nozzles for spraying under air vents, fins, those kinds of things are printed at high temperature.”

Benefits and Challenges of Using 3D Printing for Electric Vehicles

As we have already mentioned, 3D printing in electric vehicles is at one of its highest points since it began to be introduced in the automotive industry. Many companies use these technologies to create prototypes, as in the case of the new CUPRA, or simply to design parts for their existing vehicles at a lower cost. As CUPRA engineering director Dr. Werner Tietz mentions, “3D printing allows us to create prototypes quickly and cost-effectively, which helps us to streamline the development process.”

In addition, for prototypes, the cost of production using additive manufacturing is also impressively lower than by traditional methods. The same goes for manufacturing times, 3D printing offers advantages that would never have been dreamed of before by traditional methods.

Tesla making giant molds by 3D printing to be able to mass produce cars (photo credits: Tesla)

It is also worth mentioning that many brands use these softwares both for the design of their vehicles and for the operation of the vehicle’s control unit. For example, MG Motors will use Snapdragon this year in its new MG Coupé model to control the vehicle’s various functions. For their part, when test cars are manufactured in 3D, costs are greatly reduced, so testing them becomes a much cheaper task. This is the case of Tesla with its cars that are being created with the help of sand binder jetting.

Another huge benefit that additive manufacturing brings to the electric car industry is customization. The possibilities offered by Industry 4.0 technologies, such as 3D printing, to the creation and design of electric vehicles are virtually endless. That’s why several companies are already offering these possibilities. One brand we have heard a lot about is XEV, which offers the public the aforementioned YOYO model. We are talking about a car that, thanks to 3D printing, offers multiple customizable designs. Another example is the Toyota Ubox concept car, which promised to be a customizable car, but the concept has not yet been fully developed.

The small and customizable XEV and YOYO EVs (photo credits: XEV)

Despite the many benefits, there are a number of challenges in the automotive additive manufacturing industry that hinder its evolution and development. This includes manpower, since in order to design and produce 3D parts, CAD designers specialized in automotive are needed, as well as personnel such as machine technicians. But, though it is true that today there is a shortage of professionals trained in both fields, more and more people are studying for these professions.

Intellectual property theft is another major barrier facing additive manufacturing in EV. There are a number of loopholes whereby replicating parts and not being able to claim patents has become the bread and butter of the industry. There is a dearth of laws protecting the designs of the rest of the world’s creators, which is why many brands and companies are wary of starting a career in 3D printing of electric vehicles. This is even a problem with standard vehicles, as we saw with Honda’s ban of 3D printable files a few years ago.

These two challenges we have just explained are just two of the many that new technologies face in order to enter the market. There are also problems such as the speed of mass production of parts, as some would still be produced faster by traditional methods. Although it is true that we have previously talked about the fast speed of the creation of parts by 3D printing, this often refers to small series of components, prototypes or single parts. When it comes to mass production, the tables are turned. The creation of large parts is also a mission for which additive manufacturing is still very limited. As the years go by, we hope that all these challenges will become a thing of the past and that 3D printing in the EV industry will advance and establish a before and after.

What Does the Future Hold for 3D Printing Electric Vehicles?

We have talked about the past and present of 3D printed electric vehicles. But what does the future hold for this sector? Generally speaking, there are many speculations, but if one thing is certain is that following the trajectory we have observed over the last decade, we know that it will continue to grow. This is proven by the fact that there are a number of projects confirmed by some brands for 2024 that involve additive manufacturing technologies, as is the case of brands such as Liux, Seat or Cupra.

The Volkswagen ID.4 XTREME (photo credits: Volkswagen)

Another company that also hopes to make further progress in this field is the German Volkswagen. They are currently working to be able to introduce 3D printing in electric vehicles. Among them is the sportier, off-road version of its ID.4 GTX EV, called ID.4 XTREME, an electric car for which additive manufacturing plays a very important role in its design components.

Among the brands mentioned above is Liux. It is a brand of Spanish origin that aims to revolutionize the electric car industry. After years of developing different projects to bring several cars to the market, it seems that it won’t be long before the public will be able to enjoy them. Among its three possible cars, the most outstanding is the Liux Animal, an electric car that will use sustainable materials such as linen and will be printed in 3D.

What the future holds is still unknown, but what is clear is that what we have seen so far is just the beginning of a new era in the automotive industry. Elon Musk, CEO of Tesla and SpaceX, mentioned the following referring to EVs: “3D printed cars are an important step towards a more sustainable and efficient future in the transportation industry.” Another clear example of the benefits of 3D printing in this sector comes from the words of Jim Hackett, CEO of Ford Motor Company: “3D printed electric cars have the potential to revolutionize the automotive industry, creating lighter, more efficient and sustainable vehicles”.

What do you think of the different uses and possibilities offered by 3D printing for electric vehicles? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.