Breaking the Mold: Exploiting the Potential of Open-Source Large-Format Material Extrusion Solutions

Large-Format Material Extrusion Solutions have carved their legitimate place among traditional manufacturing methods. In the ever-evolving landscape of manufacturing, large-format material extrusion solutions have emerged as formidable contenders, confidently asserting their place alongside traditional methods. These robust systems, once considered niche, now stand tall, addressing application challenges that have long eluded their conventional counterparts.

Manufacturing experts of the new generation recognize the power of material extrusion. With maturity and conviction, they turn to these systems to tackle complex problems that traditional methods struggle to solve. Take aerospace and transportation, for instance. The demand for intricate, lightweight, yet structurally sound parts has surged with the advent of cutting-edge designs. Here, material extrusion steps up, offering a fresh perspective and innovative solutions.

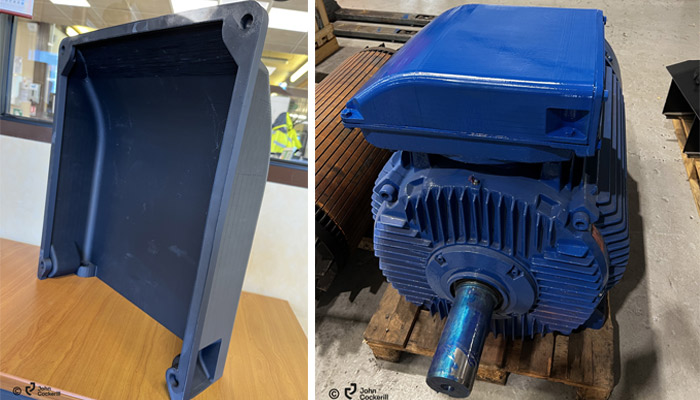

Large 3D printed pieces produced for machining applications (credits: John Crockerill)

For highly regulated industries like transportation or aerospace, efficiency and safety are key at every stage of production. At the same time, weight is also critically important. For every gram saved, there are immediate results in terms of fuel efficiency, increased payload capacity and reduced operational costs. But how to combine this need for lightweighting with safety? Industrial, large-format 3D printing using open-source materials emerged as the answer to comply with safety-requirements and certifications, such as for flame-retardant parts.

While traditional methods have their merits, they often fall short when it comes to intricate geometries and weight optimization. Material extrusion, on the other hand, thrives in this space. By layering thermoplastic materials with precision, it creates parts that defy convention. These components not only meet safety standards but also push the boundaries of what’s possible.

Take, for example, machining. Although it has its benefits, using it to create complex, aluminum aircraft interior panels is not just time-consuming but also wasteful and expensive as it involves significant material removal. Meanwhile, casting, another popular traditional method, is more suitable for producing complex shapes like engine cowlings but has its own disadvantages. Weight reduction is difficult with this process and it is almost impossible to achieve specific flame-retardant properties. Both of which are quite limiting for end-use parts. This is where additive manufacturing, and especially large-format material extrusion, has a role to play.

Credits: OMNI3D

Filling Production Gaps in Aerospace and Transportation With Large-Format 3D Printing

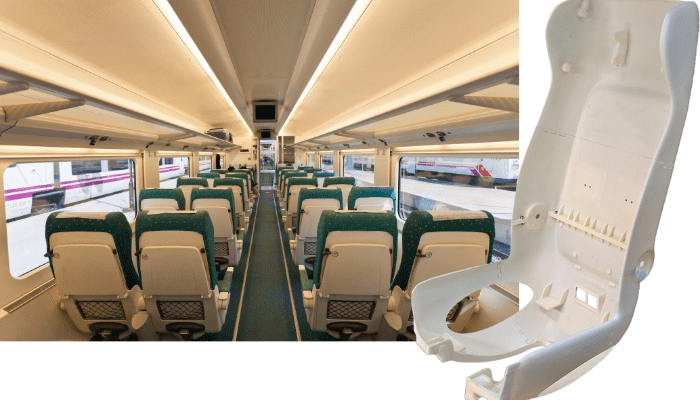

In the aerospace industry, where weight is key, material extrusion shines. It produces lightweight components without compromising strength. From intricate ductwork to cabin interiors, these 3D-printed parts redefine the art of engineering. Similarly, in railway applications, material extrusion contributes to fuel efficiency, reducing overall weight while maintaining durability, but also proved to be the preferred manufacturing method for low-volume production and replacement of obsolete parts

Large-format FDM 3D printing, especially with engineering materials, is a more cost-effective way to create lightweight, large-format and flame-retardant parts for these highly regulated industries. This is thanks to a number of benefits that the technologies offer. Namely, in-house design flexibility and customization, lightweighting through the use of lighter materials and optimization of the part, and material versatility. And there have already been cases showing just this.

Take the aerospace sector. Aviation giant Airbus turned to 3D printing as a way to take advantage of its design flexibility to produce complex geometries and intricate designs that would be difficult or impossible with traditional methods. Ultimately, this was shown by the choice of material extrusion to create lightweight air ducts with optimized internal flow channels for their A350 XWB aircraft, achieving both weight reduction and improved aerodynamic performance.

Going further, large-format 3D printing, in particular, is expected to make it easier to create complex, large end-use parts for high-speed trains, aircraft, and even cars. But that is not the only application. FDM 3D printing can be used for everything from small batch production for prototyping or testing to the replacement of obsolete parts. The latter has proven particularly important in railways additive manufacturing is ideal for creating replacement parts for obsolete components no longer in production or no longer meeting safety requirements.

Credits: OMNI3D

Open Systems Pave the Way to Standardization and Certification

Still, for these industries, safety remains paramount, as it should. And this is where just any large-format 3D printing solution is not enough. Rather, open systems are what are most likely to pave the way to more end-use 3D printed parts in the transportation, aerospace and automotive sectors.

An open system is one where materials other than those from a specific manufacturer can be used. The benefit, of course, is that it is possible to print with a wider range of materials and even updated materials. This includes materials that have been specifically certified for these sectors to meet safety standards.

Certified materials are approved by regulatory bodies such as the FAA or EASA in aviation or national and European organizations that surveil standardization and norms for railways. Recently, there has been a large movement towards the development of additive manufacturing compatible, certified materials through companies like Nanovia, whose expertise is in safety-compliant materials for the railway industry. But as material innovation continues, open systems are necessary to future-proof FDM machines in these sectors while representing an excellent investment. This is something for which companies like Omni3D, a trailblazer in large-scale, industrial FDM 3D printing are well-known.

With its open-source systems, the company ensures that these solutions find their rightful place on the manufacturing floors of highly regulated markets. Whether it’s aerospace, automotive, or rail transport, open-systems adapt swiftly, seamlessly integrating with existing workflows and to safety regulations –like norm NF EN 24424-2, which was adopted to secure the transport of railway passengers with limits on fire-related risks. In this way, it is clear that industrial FDM 3D printing is the new important technology for these sectors in the years to come.

What do you think of the use of large-format material extrusion solutions for applications in transportation and aerospace? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly newsletter here for the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.