The Not-To-Be Missed Post-Processing Solutions at Formnext 2023

Post-processing is a key step in the 3D printing process and is an increasingly important area of focus in the industry. Whether it is to improve the aesthetics of a 3D-printed part or to optimize its properties, post-processing techniques are numerous and require not only appropriate machines or tools, but also personnel trained in the process to be performed, safety measures to be observed, careful planning already at the time of part design, and more. The challenge in recent years, therefore, is the optimization of these processes and their automation, which is necessary to reduce production time and costs. On the positive side, post-processing solutions and specialized players in this market segment are growing. We saw this at this year’s Formnext, where there was no shortage of novelties and innovations, and where new players were added to solutions from players already established in the field. So we have selected for you the most interesting post-processing solutions we saw at Formnext 2023! We have listed them below in alphabetical order.

Addiblast Mars, Automated Depowdering for Metal 3D Printing

When using powder 3D printing technologies, it goes without saying that depowdering is one of the most important post-processing steps. Similar to the removal of supports in FDM, depowdering ensures that the part is fully taken out of the powder cake and all excess powder is removed. But it can be difficult to do. Slovenian company Addiblast, however, may have the solution. This year at Formnext, it has shown both its polymer and metal depowdering solutions, including the MARS03. The MARS, or Metal Additive Removal System, line has been designed and optimized specifically for the removal of final powder, even from complex geometries such as parts with internal channels. The process in the MARS03 is entirely automated though manual work is also possible thanks to the inclusion of heavy-duty gloves. The full workspace measures 850 mm x 900 mm x 1000 mm though the build plate volume is smaller at 400 mm x 400 mm x 400 mm.

.

Photo credits: Addiblast

AM Efficiency and its All-In-One Solution for Polymer Powder 3D Printing

One company that is quickly making a name for itself in the realm of post-processing is the Swedish company AM Efficiency. The company has two automated and scalable solutions that can clean, color and polish 3D printed parts. The first is the CCP-10 which has been developed specifically for post-processing parts made using desktop or small SLS machines (though is compatible with any polymer powder bed technologies including MJF, SAF and HSS) such as those from Sinterit, Formlabs and Wematter. It is office-friendly with a cabinet volume of 440 liters with a drum diameter of 55cm and depth of 30 cm. Moreover, it is possible to do cleaning, coloring and polishing all in the same unit, helping users to save space. Meanwhile, the second solution, the CCP2, has the same benefits and capabilities but is significantly larger with a cabinet volume of 990 liters and a drum volume of 65 liters. Both machines have been fully optimized not just for efficiency but for sustainability as their systems do not use toxic chemicals, ensuring no negative impact on the environment. You can find out more about their machines HERE.

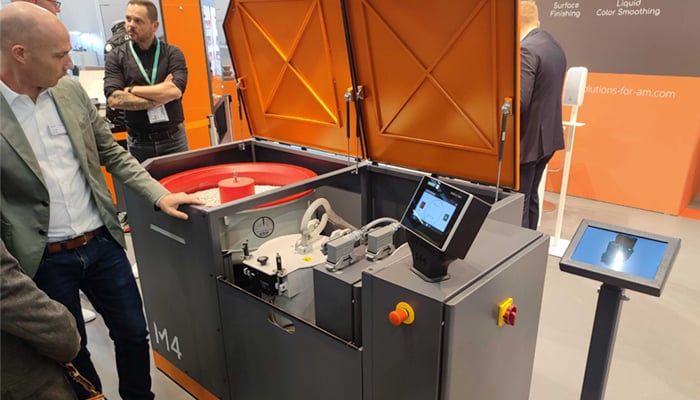

AM Solutions – M4

AM Solutions is launching no less than two new 2-in-1 solutions at Formnext: the C2 machine for sanding and chemical staining and the M4 machine for mass finishing. The latter in particular impressed us because it combines a rotary vibrator and a cleaning centrifuge in one system. It is an ideal solution for post-processing and surface finishing of small to medium-sized parts, suitable for finishing both metal and plastic components. The M4 can be used for a wide range of surface finishing processes, such as cleaning, deburring, grinding, honing, matting, polishing, etc. It also features a water recycling system that gives the machine independence in terms of location and efficiency in terms of cost and process optimization.

AMT – PostPro SFX

Another interesting post-processing solution launch at this edition of Formnext was AMT’s latest machine: the PostPro SFX, a compact desktop machine for vapor smoothing or vapor smoothing. The PostPro SFX is designed to cater primarily to users of small, but also industrial 3D printers. Among the machine’s main features, the manufacturer focuses on compactness and sustainability; in fact, the machine boasts a compact design with an 11-liter process chamber. Regarding sustainability, the PostPro SFX, which is compatible with all nylons and flexible materials such as TPE and TPU, processes materials exclusively with AMT’s PostPro Pure solvent, which is considered more environmentally friendly and FDA approved.

DLyte – 100PROCarbide

Manufacturer DLyte also presented several new solutions at Formnext 2023. The one we want to highlight most, however, is the 100PROHybrid machine for post-processing carbide parts, a first for the company and the market. Attendees will be able to see firsthand our 100PROHybrid, which is designed to handle surface finishing for cemented carbide parts as well. This solution enables precise control of cobalt leaching, which is critical in carbide machining.

Formlabs – Fuse Blast

Another must-have post-processing solution is the new Fuse Blast from Formlabs. This is an industrial solution for cleaning and polishing 3D printed parts by selective laser sintering (SLS), which complements the manufacturer’s Fuse series ecosystem, aiming to make the post-processing workflow more automated and efficient. The automated system performs blasting inside a tumbler, where residual and semi-sintered dust is effectively removed from the surface, providing completely smooth and clean parts. The optional polishing system, on the other hand, provides end-use parts with a smooth, semi-glossy, dye-ready surface finish. According to the manufacturer, combined with the integrated Fuse Sift dust management station, the new Fuse Blast reduces overall cleaning time to just 15 minutes, and labor time by 80 percent.

Reinforce3D – Delta

An undoubtedly innovative post-processing solution not to be missed at Formnext is the Delta machine developed by startup Reinforce3D to reinforce 3D printed parts. To do so, the machine uses patented CFIP (Continuous Fibre Injection Process) technology by injecting continuous fibers to improve part strength and performance. The technology is unique in that parts are usually strengthened during the manufacturing process. Delta’s goal is to automate the process for industrial scale and ready-to-use prototype production.

Rivelin Robotics

This is not the first time we have talked about Rivelin Robotics in particular at Formnext. In fact, the startup won the Formnext Startup Challenge last year thanks to its NetShape robotic solution for metal AM parts and components, capable of removing supports and working on the surface finish of parts in an automated way. This year the startup returned to the show with its own booth and new solutions. The company displayed several AM post-processing cells for metal, including the NS0, NS1 and NS2, each of which contains robots (from partner Yaskawa Europe) controlled by Rivelin’s Netshape software. The result is an automated solution for substrate removal and finishing that reduces defects in parts by up to 90 percent, resulting in a significant reduction in operating costs and the elimination of human risk and variability.

Schmitt Ultraschalltechnik – SLA Clean

German manufacturer of post-processing solutions Schmitt Ultraschalltechnik presented at Formnext a series of solutions dedicated to cleaning parts produced with SLA technology. While one of the most commonly used products for cleaning resin parts is isopropanol alcohol, this solution surprises because it focuses on a safer approach for operators and is environmentally friendly by eliminating the use of isopropanol. SLA Cleaning’s solutions work through a rotating ultrasonic cavitation system (electronic brushing). By placing the parts in a metal basket, this process, via an isopanol-free liquid allows resin residues to dissolve even in hard-to-access areas without damaging the material surface.

Xioneer – Vortex XP

Xioneer presented its modular, automated post-processing solution, the Vortex XP, at Formnext. The system includes three units each dedicated to one process: media removal; rinsing and drying or dyeing. The units can be purchased individually, but what is interesting is the possibility of combining them by also being able to add a robotic module into a fully automated Vortex XP system. At their Formnext booth, Xioneer has combined two XP190G units and an XP190D unit into a single post-processing station. In addition to the three stations mentioned, a tray is also added here where the robot places the finished and post-processed parts, forming a fully automated and complete post-processing cycle.

What interesting post-processing solutions have you seen at Formnext 2023? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*All image credits: 3Dnatives