The Integration of 3D Printing in Hospitals

Over the years, 3D printing has gradually made its way into the medical field. Orthopedics, ophthalmology, dentistry and traumatology are just some of the specialties that are now using the technology to optimize their activities. And for good reason. Because of its characteristics, additive manufacturing allows for the design of all types of parts quickly and at a lower cost, to name a few these include drugs, insoles, orthotics, prostheses and even surgical guides. There are countless applications of additive manufacturing in the healthcare sector. But while more and more initiatives are emerging, what about the integration of 3D printing in the hospital environment? Between advantages, challenges and limits, 3Dnatives comes back to the question, which is still the subject of many debates among professionals, patients and the general public.

Several years ago, additive manufacturing was already being introduced in hospitals in several countries. In the United States, for example, Statista, which produces statistics on various topics, found that only 3 hospitals with in-house 3D printing facilities in 2010, compared to 113 in 2019. A meteoric increase, which testifies to the interest of the medical profession in the technology. On the other side of the Atlantic, in France in particular, additive manufacturing is also gaining popularity in university hospitals, especially in Brest and Besançon. There, the technology is being deployed for a variety of reasons, from helping practitioners with their therapeutic choices to helping patients better understand their diagnoses.

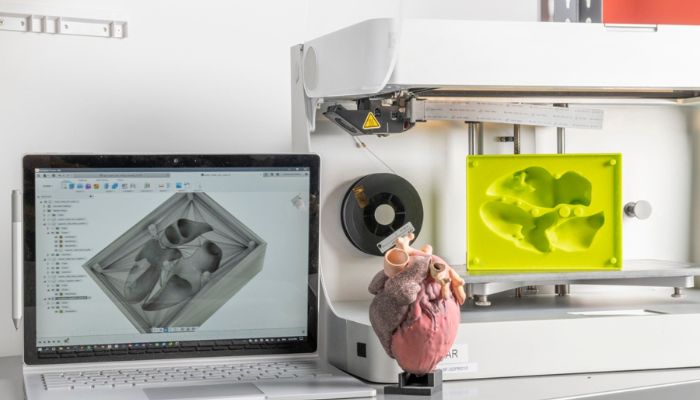

The 3D printers of the I3DM platform of the University Hospital of Besançon (photo credits: University Hospital of Besançon)

3D Printing in Hospitals: A Variety of Uses

“Between saving operating time, developing personalized surgery and low-cost manufacturing, I see few limits to the use of 3D printing in hospitals. That’s why I believe in it so much,” says Samuel Guigo, a radio technician in charge of 3D printers at the University Hospital of Brest. Like many others, the practitioner is attracted by the advantages offered by the technology. Like in the other many industries that use 3D printing, additive manufacturing is used for a variety of purposes in healthcare institutions. And in hospitals, the main use is probably the creation of surgical guides.

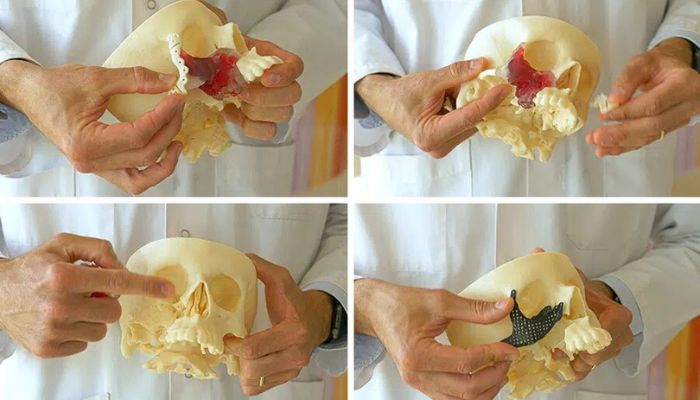

Aurélien Louvrier, a maxillofacial surgeon at the University Hospital of Besançon, explains: “This allows us to be reassured and to consider in a more serene way surgical interventions that at first glance seem quite complex. The surgery is already performed virtually, and you arrive in the operating room with less apprehension. Thanks to the virtual surgery and the 3D printing of anatomical models, we can perfect the analysis of each case and consider different surgical strategies. Once the most suitable solution has been chosen, the procedure can be carried out with peace of mind. Many surgeons at the Besançon University Hospital have adopted this technology. Created in January 2020, the I3DM platform currently performs about 150 planning and 3D printing procedures per year.”

If printing 3D models allows practitioners to better understand anatomy and pathology, it also allows patients to better understand what they are suffering from. Indeed, with a physical representation of the pathology, the nursing staff is able to present concretely to patients what the problems are and how they will proceed to try to fix them. In Barcelona, for example, in the pediatric hospital Sant Joan de Déu, the surgical team managed to remove a tumor in the cheekbone of an 11 year old boy with the help of BCN3D solutions. A perilous operation that was facilitated by the planning and simulation of the surgical act. Proof that this application allows to reassure both surgeons and patients, and contributes to improve the patient/practitioner relationship. But to summarize the interest of additive manufacturing in the hospital environment to this effect would be too simplistic.

3D printed reproduction of a child’s tumor (photo credits: SJD Barcelona Hospital)

Numerous Advantages

As mentioned above, technology offers practitioners the opportunity to practice before performing surgery. And this practice logically leads to lower costs for healthcare institutions as well as higher success rates. Surgeons who use 3D printed surgical guides explain that this application allows them to reduce operating time while improving precision, thus reducing bleeding, the risk of infection and even the number of repeat operations. This is a very important fact for health care institutions, as the operating room is one of the biggest expenses for hospitals. Dr. Louvrier explains: “It’s a real win-win situation, as it improves the precision of the surgical procedure and reduces the operating time. We don’t create financial benefits, but we do save money; if we save one hour of operating time, the savings are already made.”

Additive manufacturing in hospitals also favors the development of new therapeutic approaches. Although most of the time they are considered only as health care institutions, university hospitals are also places where research is very important. Thanks to the capabilities of 3D printing, which can be used to design custom-made medical devices such as prostheses and orthoses, as well as medicines, many scientists hope to be able to offer better care to patients in the coming years. However, to do so, certain conditions are necessary.

During the first wave of Covid-19, the AP-HP installed no less than 60 3D printers (photo credits: LP/Olivier Arandel)

A Growing Ecosystem

As one might expect, in order for 3D printing to be properly integrated into a hospital environment, it must be a hospital project. Indeed, it is only when management decides to invest fully that a 3D technology department can be created. Mr. Louvrier recalls the beginnings of 3D printing at the Besançon University Hospital: “We realized that many teams were using 3D technologies, but each one on its own. So we suggested to management that we centralize this activity and bring it up to standard from a regulatory point of view.” Following this, the hospital devoted itself to creating premises and equipping itself with dedicated equipment that complies with the standards for designing medical devices. Since then, Ultimaker and Formlabs 3D printers are used daily to support the practitioners. A full-time hospital engineer is dedicated to this activity.

Obviously, integrating technologies such as selective laser sintering or even traditional manufacturing methods is much more complicated for a hospital. Indeed, this type of process requires premises that comply with numerous standards, representing a cost that is too high for healthcare institutions. Therefore, when an implantable part, such as a plate or a custom-made implant, is needed, hospitals turn to the industry at large. And even though third-party intervention is required, the manufacturing process is faster. The practitioners and the hospital engineer can model the medical device themselves, and they send the 3D file to the partner company in charge of the design. With this new hybrid workflow, a customized, personalized medical device can be produced more quickly.

Hospitals also use outside companies (photo credits: F3DF)

Limits to the Integration of 3D Printing in Hospitals

However, 3D printing has not yet been integrated in all hospitals today, notably as a result of a number of obstacles that are still present. Slightly addressed before, regulation is the main challenge facing additive manufacturing. Guigo explains, “The regulatory aspect and the ability of hospitals to produce their own medical devices in a certified manner is among the main limitations. We could also mention the fact that we ourselves design, print and implant a printed medical device, surely in my eyes the evolution to strive for.”

At the same time, training in 3D technologies is also a barrier to the full democratization of 3D printing. At present, too few caregivers have the opportunity to follow training courses in 3D technologies. That’s why, again in Besançon, within the University of Burgundy Franche-Comté, a University Diploma (DU) was created in 2020 to address this problem. Entitled “DU I3DC”, for 3D Printing in Surgery, this course includes theoretical courses, intended to explain the various regulations, and practical courses, where students learn to model and print 3D parts. Open to engineers and caregivers, this DU aims to generalize the technology in the hospital environment but also in the private sector.

Towards a Democratization of Technology in Hospitals?

And if additive manufacturing as we know it is gradually spreading, bioprinting is also beginning to be used in university hospitals. In Marseille, the French company Poietis, expert in the development of bioprinting solutions, announced a new partnership with the Laboratory of Cell Culture and Therapy (LCTC). Together, the two companies aim to provide AP-HM, Assistance publique – Hôpitaux de Marseille, with a platform to design implantable biological tissues.

Eventually, the technologies are likely to become commonplace in hospitals. The potential for 3D technologies in the hospital environment seems immense, given its advantages, especially in terms of cost and speed. Just a year ago, Samuel Guigo confided on this subject “not yet having any idea of all the possible uses of printing in the hospital sector.”

What do you think about the integration of 3D printing in hospitals? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*Cover Photo Credits: Formlabs

Wonderful. Glad that Industry 4.0 has been applied in the medical field.

makes you wonder how uch farther we are from literally printing our own organs from home, could still be fiction but in a couple years maybe

https://3dprinterchat.com/human-organs-are-being-developed-using-bio-3d-printing-techniques/

I’m constantly searching on the internet for posts that will help me. Too much is clearly to learn about this. I believe you created good quality items in Functions also. Keep working, congrats!