What is the Future of Metal Additive Manufacturing?

Earlier this year, research firm IDTechEx published a report on metal additive manufacturing, estimating that its value would reach $18.5 billion within 10 years, showing a gradual recovery of the market. As part of this study, the firm conducted an analysis of the future of the metal additive manufacturing market by comparing the different processes that exist, seeking to understand the major trends in the sector but also possible future sources of revenue. Powder bed processes, concentrated energy deposition (CED), wire extrusion: which technology should you focus on? Where does the future of metal 3D printing lie?

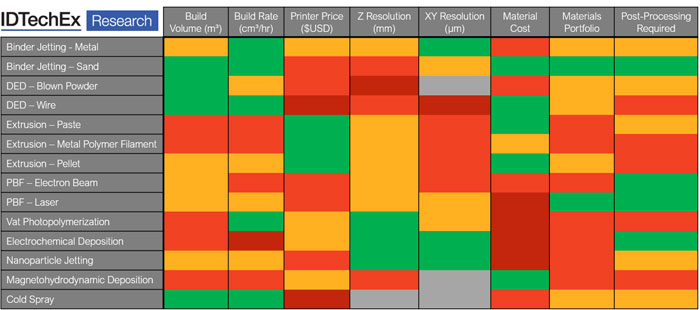

Fourteen 3D printing processes were analyzed and compared in the IDTechEx study. Among them, there are of course the most well-known technologies such as Binder Jetting, DED, extrusion (whether with granules, paste or even filaments), laser powder bed fusion, but also less popular processes such as electrochemical deposition or cold spray. For each process, criteria such as print volume, accuracy, price of the machine and material, and necessary post-processing steps were compared, with the aim of evaluating strengths and weaknesses.

IDTechEx compared 14 metal 3D printing processes according to specific criteria (photo credits: IDTechEx)

Current Market Trends

As with many other technologies, price and build volume are two key factors to which users are particularly sensitive. Starting with the former, you probably know that metal powder is expensive, especially when it comes to uniform powder. This is a major barrier to entry for many companies, preventing them therefore from turning to powder processes, even though there are many on the market today. This is where we see a trend emerging: the development of extrusion technologies, more specifically the deposition of metal filaments – or rods – and granules. One example is manufacturers such as Meltio, who has developed a machine that combines two types of raw materials to lower the cost of a 3D printed part. More and more players specialized in FDM/FFF have also presented extruders capable of supporting metallic materials.

Of course, some processes are historically based on a raw material other than metal powder – DED comes to mind, for example, but also sand powder binding. The main disadvantage of these two technologies is the entry price of the machines on the market. If you look at the IDTechX comparison chart, you will see that these are the most expensive 3D printers. A user looking for a more economical solution probably would therefore tend to go for an extrusion solution.

If we now look at build volume, we see that the metal additive manufacturing market offers a wide range when it comes to size. Users can design smaller parts on laser melting machines for example, but also large components via processes like cold spray. So the trend is encouraging, users would not be held back by the volume currently on offer. As a result, they can expand the range of possible applications and thus increase the use of metal 3D printing.

Current solutions allow the design of parts of varying sizes (photo credits: 3D Systems)

What is the Future of Metal Additive Manufacturing?

According to the results in the survey, it would seem that a metal 3D printer combining a relatively low entry price (or even with a lower raw material cost) with a large build volume would be a sensation for users. Mind you, when we talk about the price of the machine, we are talking about $500,000. Today’s solutions with a large printing volume cost several million dollars. In addition to this, the key properties of a metal 3D printer are surface finish and tensile strength: users want a solution that is capable of designing quality parts that meet the most demanding requirements.

Finally, the IDTechX report shows that a balance must be struck between manufacturing speed and resolution. Current technologies often sacrifice one of the two – typically, good surface finish is favored at the expense of high material throughput. What if we could combine the two? If some polymer processes have been able to do this, such as Carbon’s DLS technology or EnvisonTec’s cDLM, why not metal additive manufacturing? This is what we will have to observe in the next few years: the combination of speed and resolution to go towards the production of finished parts in large series. In any case, you can be assured that we will certainly be keeping an eye on this! In the meantime, you can read the whole study HERE.

What do you think will be the future of metal additive manufacturing? Let us know in a comment below or on our Linkedin, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*Cover Photo Credits: Lasercutting