Curling in 3D Printing: What It Is and How to Fix It

As you probably know by now, the term additive manufacturing encompasses a number of innovative technologies that enable parts to be manufactured faster and with fewer materials than subtractive manufacturing methods. However, it is not infallible. Indeed, for each printed part, numerous parameters must be taken into account to avoid printing errors. One common problem in 3D printing is curling. Though similar to another well-known phenomenon, warping, they are not exactly the same. But what do these two closely related but distinct notions mean?

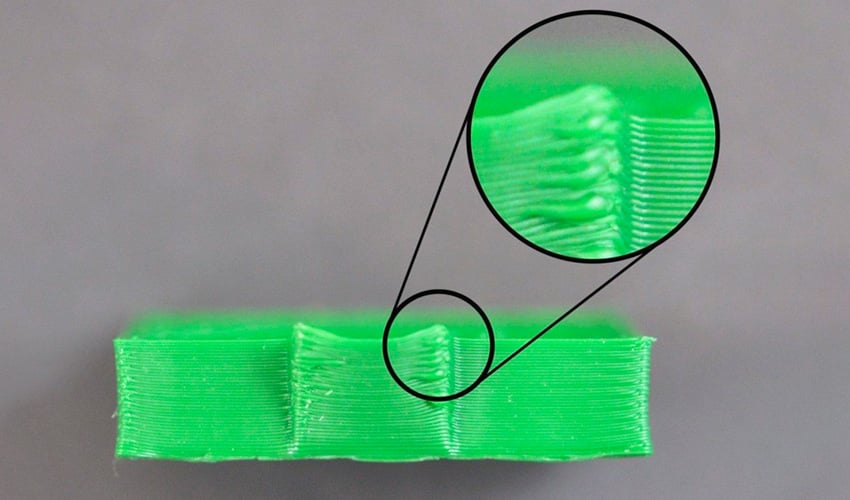

Curling, also known as rough corners or overextension on corners, is a deformation of the upper layers of the 3D-printed object, particularly visible at the edges, which can cause the part to become defective. Warping is a similar phenomenon, but affects the lower layers of the part, causing it to detach from the printing plate. Another term, delamination, on the other hand, is characterized by the separation of the various printed layers, the same phenomenon taken to extremes. Let’s take a closer look at the causes of these anomalies, and the solutions to be implemented to avoid them.

The curling phenomenon leads to deformation of the part

Essentially, curling in 3D printing (along with the other phenomena) is caused by too great a temperature difference between the material at the time of extrusion and the surrounding air (as soon as the filament leaves the nozzle, it is suddenly cooled to room temperature). This is why this problem often arises during FDM 3D printing.

As this process involves melting the 3D filament, its temperature is high – around 200°C for PLA, for example – creating a sharp contrast with that of the ambient air. Curling also occurs with DED technology, which requires the metal to be heated to extreme temperatures, creating an even more significant temperature disparity with the part.

How to Avoid Curling in 3D Printing

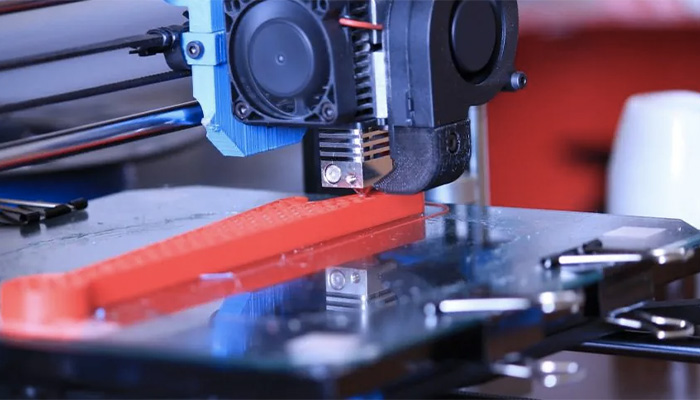

As you can see, to avoid curling in 3D printing, temperature control is key. If you’re using a plastic like ABS, the recommended extrusion temperature is between 230 and 260°C. Ideally, set your 3D printer between these two temperatures to avoid extrusion difficulties on the one hand, and anomalies such as stringing, curling, warping or delamination on the other.

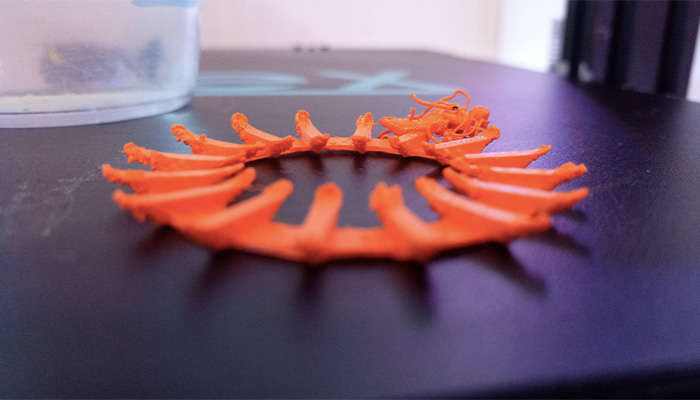

ABS can deform easily if printed in poor conditions (photo credits: Sculpteo)

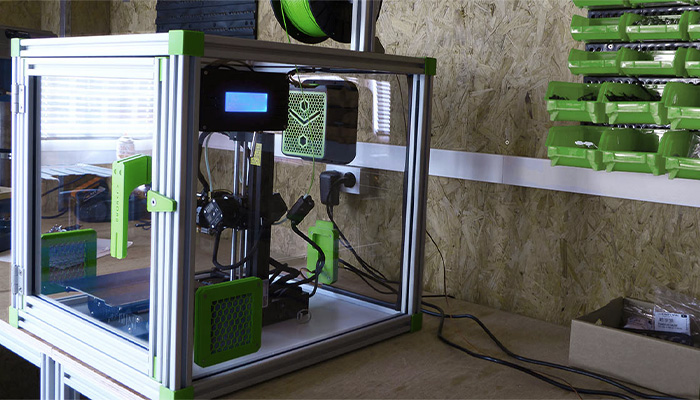

In addition, using a 3D printer with a closed or heated enclosure reduces curling by reducing the temperature difference between the part and the surrounding air. A closed enclosure also protects the part being printed from air currents and the sudden drop in temperature they generate. If your 3D printer doesn’t have a closed enclosure, you can place it in a printing cabinet.

To prevent curling in 3D printing, the printing plate is also heated to prevent the layers from cooling and expanding too quickly. In the case of ABS, it must be heated to between 80 and 130°C. If these conditions are not met, the plastic may shrink by around 1.5%, or even more, depending on the size of the part.

If we compare this material with PLA, the latter has a melting temperature of between 170 and 180°C, i.e. lower, and does not necessarily require a heated printing plate. This thermoplastic is less prone to curling. PETG, on the other hand, has almost the same characteristics as ABS, and needs to be placed in the right conditions to avoid warping.

In addition, most 3D printers have fans to solidify molten filament. This system is essential; however, it is necessary that the settings are correct to avoid, once again, too great a temperature contrast with the outside, which would cause the part to warp. Another measure to avoid curling or other warping in 3D printing is to reduce the height of the layers to encourage them to adhere to each other.

The 3D printer can be covered with a printing box to protect it from drafts (photo credits: Alveo3D)

Have you ever experienced curling in 3D printing? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*Cover Photo Credits: Simplify3D