The Complete Guide to WAAM in Metal 3D Printing

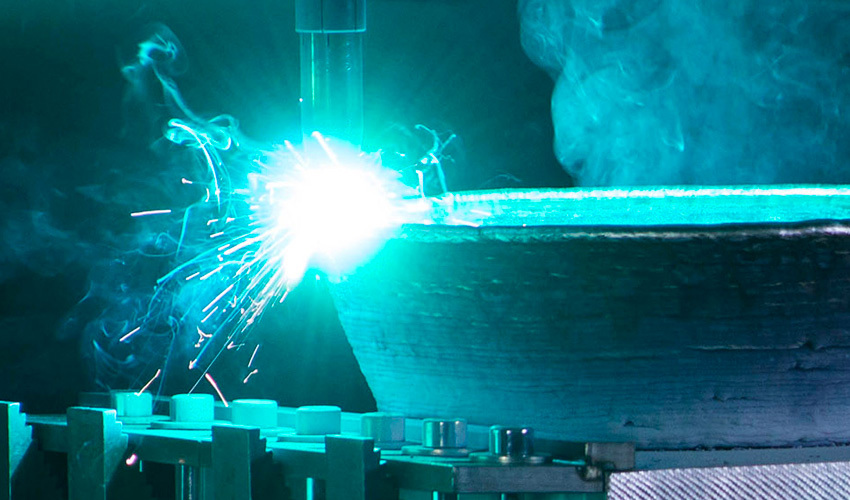

Wire Arc Additive Manufacturing (WAAM) falls under the umbrella of Directed Energy Deposition (DED) 3D printing. DED technology is a metal 3D printing technique that involves depositing a metal material in powder or wire form by means of a nozzle mounted on a multi-axis arm. A focused energy source, i.e. a laser or electron beam or plasma, is used to melt the material as it is used to build the part layer by layer. In the case of the WAAM, an electric arc is used as the heat source, inspired by arc-welding.

WAAM technology is based on the principle of various automated welding techniques using robotic systems: metal-inert gas (MIG) or metal-active gas (MAG), tungsten-inert gas (TIG) or plasma arc-wire (PAW). There’s also the Cold Metal Transfer (CMT) welding process, derived from MIG and created by Fronius in 2004. Various metals are compatible with WAAM. These include titanium, aluminum, nickel and steel alloys, among others.

The 3D-printed propeller by Naval Group (photo credits: Naval Group)

Applications for WAAM 3D Printing

Like with other DED processes, WAAM is often used to repair equipment and reproduce parts that are no longer manufactured, in order to maintain older machines. However, the technology can also be used to manufacture complete parts. WAAM is used in particular in the aeronautics, aerospace, automotive, energy and defense sectors. It is used to manufacture prototypes, molds, single parts and small series. Its use for mass production is still under review, however, though it is particularly well-suited to the creation of large, metal parts.

For example, in the aerospace sector, Naval Group used WAAM technology to manufacture a propeller for the mine-hunting ship Andromède. In the energy sector, Vallourec used WAAM to produce the first sealing ring to ensure the safety of EDF Hydro’s hydroelectric installations, measuring one meter in diameter and weighing 100 kg. In the robotics sector, MX3D also used the technology to produce a structural steel connector. MX3D also uses WAAM to manufacture pipe connectors for the oil and gas industry, as well as gears and custom components for large machines. MX3D even built a bridge in Amsterdam using the WAAM process! Moreover, Relativity Space used this technology to build its Terran 1 light launcher. The production of molds for the plastics industry is another common application.

The Takenaka steel connector from one of Japan’s leading architectural firms (photo credits: MX3D)

WAAM 3D printing offers many advantages. First and foremost, printing speeds are high, which has a positive impact on production times. Costs are also lower than for machines using powder-bed fusion technologies, in particular Selective Laser Melting (SLM). WAAM technology also stands out for its ability to produce extremely large parts. As already mentioned, a wide range of compatible metals is also available.

Limitations of the Technology

The WAAM process also has its limitations. Since it allows faster printing, the detail and dimensional accuracy of the parts are less well reproduced than with powder-bed fusion technologies. Parts manufactured using WAAM technology can have defects such as internal porosities, which can degrade the mechanical properties of the part, either statically or in fatigue (when the part is subjected to various forces, resulting in damage). This is particularly true of aluminum parts.

Residual stresses are another anomaly that can occur with WAAM technology. They can lead to deformation of the part’s dimensions and/or shape, notably through curling, warping or delamination. All these phenomena are characterized by deformation on the layers of the printed part, be it the top, bottom or, in the case of delamination, all the layers. These deformations are caused by the very high working temperature and the technical nature of the materials. They will result in the part holding up poorly when forces are exerted on it.

Vallourec uses WAAM technology for power plants (photo credits: Vallourec)

To limit the occurrence of these defects, it is necessary to know all the WAAM parameters in order to set them as accurately as possible. This will ensure a consistent molten metal deposit, as well as constant heat. Unwinding speed, feed speed, current, voltage, layer thickness, protective gas flow rate and bead spacing are all essential factors in ensuring a smooth process.

However, there are also technical solutions to mitigate these anomalies. These include mechanical work-hardening, or rolling. This method involves exerting pressure on the weld bead with a roller during the cooling phase. This reduces porosity. To reduce residual stresses, the material can be preheated. Note that some materials and alloys are more susceptible to cracking or delamination than others, e.g. aluminum-copper, aluminum-titanium and aluminum-iron alloys.

As with other additive manufacturing technologies, a significant amount of finishing post-processing is also required. Post-processing is carried out using a traditional machining process. In some WAAM applications, machining can be carried out during the printing phase, using a second robot.

WAAM 3D Printer Manufacturers

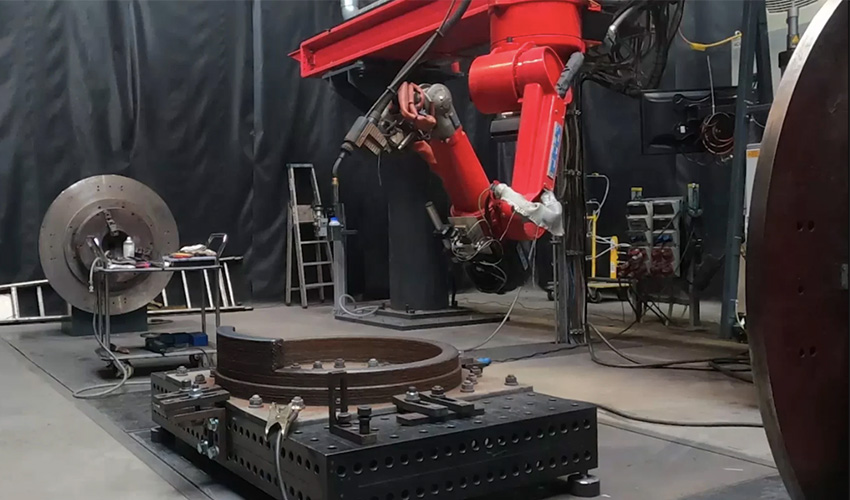

An MX3D 3D printer using WAAM technology (photo credits: MX3D)

Manufacturers of 3D printers using WAAM technology include Prodways, whose 3D printers work with the WAAM-TIG process, Norsk Titanium and its in-house Rapid Plasma Deposition (RPD™) process, GEFERTEC, MX3D, WAAM3D and Lincoln Electric, among others.

What do you think of WAAM technology? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*Cover Photo: Relativity Space’s Terran 1 rocket under construction (photo credits: Relativity Space)