The Best Micro 3D Printing Solutions On the Market

3D microprinting, also known as micro-scale printing, is a micro-fabrication technique that allows the design of very small sizes, at the micrometer scale and below. Particularly popular in the electronics industry, it is growing steadily, with more solutions available on the market. Micro 3D printers are therefore able to deposit successive layers of material to form a part that is both tiny and highly detailed. In addition to the electronics sector, where they are used to miniaturize devices, these machines are increasingly used in the health and optical sectors. This is a review of the 3D microprinters on the market, including the most popular, whether they are based on resins, powders or glass.

Boston Micro Fabrication – 2μm Series Printer

With a very high resolution, Boston Micro Fabrication’s 2μm series is compatible with numerous materials. The 3D printer is particularly suitable for the development of prototypes that are true to CAD and have maximum likeness to the final product. The printer’s name is derived from its movement platform which offers a resolution of up to 2μm. In addition, the step-and-repeat method enables printing on a large area. Other attributes of the printer include real-time image monitoring, exposure compensation and autofocus. You can choose between the microArch® S130 and the microArch® S230. The difference between the two is, firstly, the build platform. The latter is larger, coming in at 50 x 50 x 50 mm, whereas the microArch® S130 is 50 x 50 x 10 mm. The microArch® S230 can print with ceramics in addition to light-sensitive resins.

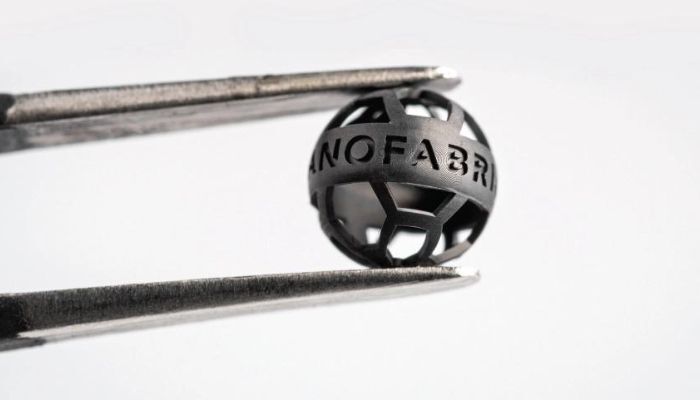

Nano Dimension Offers a Micro DLP Solution With Fabrica 2.0

The next printer belongs to a company that even has Nano in its name, showing its overall commitment to micro 3D printing. However, it might come as a surprise to know that the Fabrica 2.0 3D printer does not originally come from Nano Dimension at all. In fact, it was developed by Nanofabrica, which was acquired by Nano Dimension in 2021 and renamed Fabrica Group. Though now the Fabrica 2.0 is purely under Nano Dimension, it was made using Fabrica’s resin micro 3D printing technology. The solution uses Micro DLP AM and according to Nano Dimension allows for speeds that surpass other micro manufacturing processes thanks to printing rates that are 5 to 100 times faster. It is ideal for high-mix, low-volume batches, such as for tooling, and has a resolution of 1.9 µm with a layer thickness going between 1 to 5 µm. The print dimensions are not overly large at 50mm x 50mm x 100mm, but the company puts a focus on its precision, considering it to be “additive manufacturing micron by micron.”

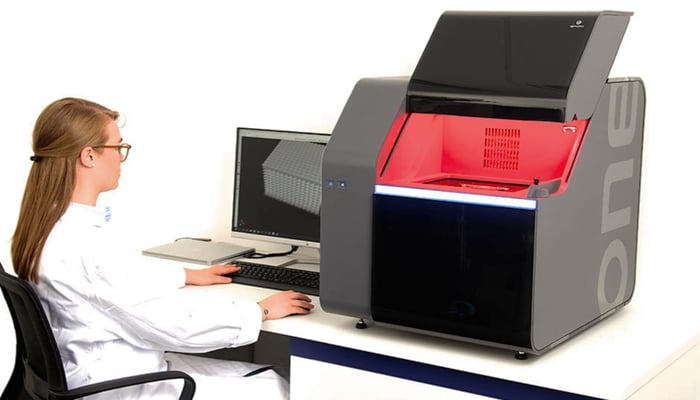

NanoOne by UpNano

UpNano is an Austrian company for high-resolution 3D printing systems. In addition to the production of printing systems and operating software it offers process-optimized materials and accessories. Its NanoOne micro 3D printer is based on multiphoton lithography and combines the precision of 2-photon polymerization with a throughput of less than 450 mm³ per hour. This makes the system suitable not only for scientific research but also for batch and small series production of industrially applicable micro parts. The major focus of NanoOne is high-resolution bioprinting, i.e. 3D printing with living cells and thus the combination of polymer material and cell research, thanks to the speed and technology of the system.

MICROFAB-3D by MicroLight3D

MicroFAB-3D is open 3D microfabrication platform for research applications. It is a high-resolution 3D printing system based on direct laser writing technology with two-photon curing. According to MicroLight3D, this technology makes it possible to eliminate the traditional “layer-by-layer” approach, to print more complex geometries, without the need for support materials or post-processing. The print size is adaptable through software provided by the company and can be as small as 0.2 microns wide.

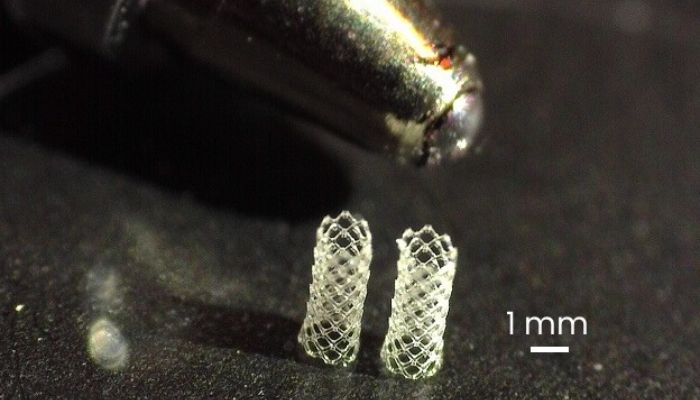

For printing materials, Microlight3D provides a range of 10 proprietary photosensitive resins optimized for two-photon curing technology. However, the technology is compatible with a wide range of commercially available resins and certified biocompatible materials, such as hydrogels or proteins, to make micro-medical devices.

In fact, MicroFAB-3D is designed for a variety of fields such as microfluidics, micro-optics, cell culture, micro-robotics, or meta-materials.

2 mm high stents printed in a biocompatible material with the Advanced function of MicroFAB-3D. Photo credit: MicroLight3D

Nanoscribe Quantum X Shape

The Nanoscribe Quantum X Shape uses the innovative technology of two-photon grayscale lithography (2GL ®). With the voxel tuning capability of this technology, very accurate, down to micro-structured surfaces can be printed for 2.5D sTructures. For biomedical devices, micro-optics and micro-electromechanical systems (MEMS).

The 3D printer is particularly suitable for rapid prototype development. With the nanoConnectX, a multi-user configuration, the process can be followed from other locations. In addition, it should be mentioned that the XLF Print Set prints centimeter-sized objects up to 50 x 50 x 12 mm³ relatively quickly. This printer is suitable not only for the micro, but also for the macro range.

MultiPhoton – MPO 100

As a subsidiary of Heidelberg Instruments Mikrotechnik GmbH, Multiphoton Optics GmbH introduced its micro 3D printer designed for industry in 2022. Named MPO 100, its hardware has a dimension of 1300 x 110 x 1950 mm and a total weight of 1000 kilograms; as for the build area, its dimensions are 100 x 100 x 100 mm. The manufacturer emphasizes that this represents a high printing volume for 3D microprinting, thus inspiring users to produce complex microstructures. You should also know that the MPO 100 is a multi-user tool that is applied for two-photon polymerization (TPP). TPP is a direct laser writing technology in which an interaction between light and matter occurs exclusively within the space of the directed laser spot. Finally, it is important to know that the MPO 100 finds its application especially in optics, photonics, mechanics and biomedical engineering.

The Hammer Lab35 3D Micro-Printer

Developed by the Austrian manufacturer Incus, the Hammer Lab35 machine allows the design of metal micro-parts mainly for the medical, electronic and jewelry sectors. It is based on the Lithography-based Metal Manufacturing process which uses the principle of photopolymerization and metal powders dispersed in a photosensitive resin. Once the printing is completed, the green parts are removed from the print cake in only 15 minutes according to Incus. The post-processing steps follow: cleaning, debinding and sintering to obtain all the properties of the metal. As for materials, the Hammer Lab35 is compatible with stainless steel, copper, titanium and all metals compatible with MIM.

Exaddon and Its Ceres System for Microfabrication

The Swiss company Exaddon is dedicated to the development of high-precision 3D microprinting solutions for a wide range of applications. They stand out for their innovative CERES metal additive microfabrication system designed for users, scientists and companies. CERES has the capability to create complex metal parts at micrometer scale, in sizes ranging from 1 µm to 1000 µm, at room temperature and without requiring post-processing steps. The system is operated using the CAPA software, developed by Exaddon, which has an intuitive interface that allows all parts to be connected. In addition to being able to print with pure metals (copper, gold, nickel, silver), it has sub-micrometer resolution, making it ideal for research centers looking to innovate in this field. You can learn more about the manufacturing method in this video:

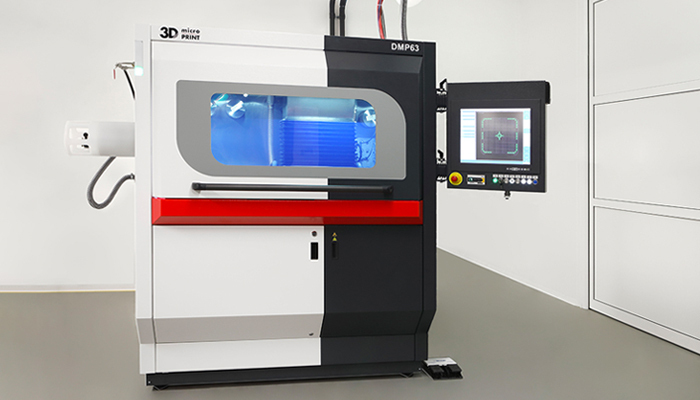

3D Microprint – DMP60 series

The DMP60 is the second micro laser sintering machine series from German manufacturer 3D MicroPrint (founded in 2013 in a collaboration between EOS and 3D-Micromac). It is an industrial machine series which offers high productivity when used with nonreactive and reactive materials. Its zero point clamping system offers increased time savings and simple post-processing.

The DMP60 features a laser spot size of under 30 micrometers for high precision printing. With a building platform of 60mm and maximum build height of 30mm, the printer is ideal for small parts, and the layer thickness of between 1-5 micrometers allows for a detailed final design. For those concerned with the price, the initial cost is available on request and the gas tight design with air locks means low running costs.

Nanogrande MPL-1

Nanogrande is a Canadian based 3D printing company which offers advanced microscale printing using their FluidBedTM patented technology. The MPL-1 is intended for industrial applications using thin metal powders, with a maximum build size of just 250cm3. It has a build speed of 1 minute/layer and optimal particle size of 0.3-10 microns.

The MPL-1 uses a proprietary powder and chemicals, including stainless steel, copper and titanium. The printer is usually used for nanoparticles but can also be used with micron-sized particles.

According to the manufacturer, the printer currently serves industries with minimal barriers to entry, which require metal fabrication with a small build size. These include watchmakers, jewelry makers, and manufacturers of miniature electronic components.

FemtoPrint and Glass Micro 3D Printing

FemtoPrint is an unusual one not only on our list but in 3D printing in general because it actually uses glass as its material. The Swiss company is dedicated to the making of 3D printed microdevices in glass and other transparent materials and offers services, solutions as well as its own platform, named as well FEMTOPRINT®. They say that the solution is an ideal 3D printing platform for academics as well as industrial applications. Essentially, the technology works by using light as a powerful ink source. The beam, which is focused inside the glass, modifies the refractive index ( the light bending ability of an optical medium) and density of the material. On the website, the company notes that “Depending on exposure parameters, waveguides can be formed to realize complex integrated optical components or three-dimensional structures with additional chemical etching.” For the final parts, users can expect a resolution of under 1 µm and the company can also combined 3D microdevices with metal deposition and surface functionalization for unique 3D structures.

What do you think of our list of the top micro 3D printing solutions? Did we miss any? Let us know in a comment below or on our Linkedin, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

We need to find a company to 3D print our prototype.