The 3D Metal Market Estimated to be Worth $18.5B by 2032, Showing Recovery After Pandemic

The research firm IDTechEx has published its latest report on the metal 3D printing market entitled “Metal Additive Manufacturing 2022-2032: Technology and Market Outlook.” According to the report, this market is expected to reach a value of $18.5 billion within the next 10 years, even though forecasts made in 2020 were inconclusive as a result of the COVID-19 crisis. Indeed, the aerospace sector, an undisputed user of metal processes, recorded a sharp decline due to the health crisis. However, with the gradual recovery of activities, the metal 3D printing market is showing some rather positive signs, with an estimated annual growth rate of 18.8%. But which factors are driving this recovery? Can we expect a wider adoption of 3D metal technologies in the coming years? And on the other hand, what is holding back their growth?

In 2020, the firm emphasized the importance of metals, convinced that they would drive market growth. In 2022, the market is still looking for innovation in terms of materials. We know that, compared to polymers, the choice is relatively limited, with the material remaining expensive. Manufacturers are looking for alternatives and are opting for high-performance polymers or composites, for example. However, in demanding sectors, metals remain the number one choice. This is why more and more startups are exploring new solutions, seeking to develop high-performance alloys.

Key trends in the metal 3D printing market according to the report (photo credits: IDTechEx)

While some barriers seem to be breaking down on the materials side, the study says the same is true for the price of the machines. We are only at the beginning, but some manufacturers are breaking the amounts we are used to seeing on laser fusion printers – 500,000 euros, even a million. Startup One Click Metal, for example, has set its sights on offering a $100,000 metal 3D printing solution. These types of initiatives can help the market grow by removing some of the barriers to entry. Though of course, it remains to be seen whether they are sustainable and equally effective.

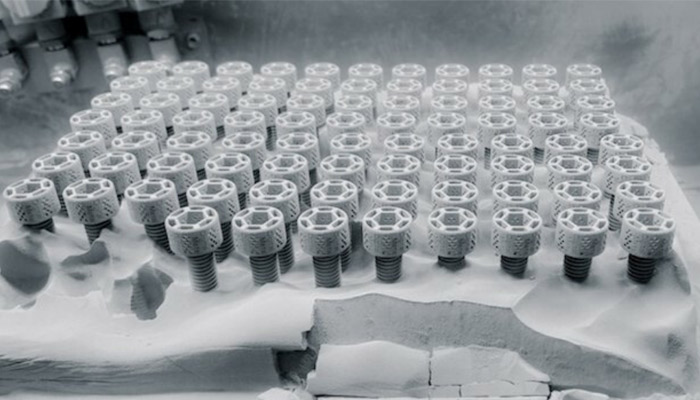

Finally, the report states that one of the factors driving market growth is the development of powder metal bonding, driven in particular by the companies Voxeljet and ExOne. The process has a number of advantages, including the possibility of designing large parts. This is a market that we have been following closely for several months now and that we will continue to monitor! Powder bonding is obviously not the only technology in the sector and it is also interesting to see the developments in DED or EBM, especially at a time when manufacturing processes are being relocated.

Metal binder jetting is a process to follow closely (photo credits: Digital Metal)

If you want to know more about the evolution of the metal additive manufacturing market, you can download the report HERE. Let us know in a comment below or on our Linkedin, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*Cover Photo Credits: Sigma Labs