Better Design Parts Made With Additive Manufacturing: Test CDS Software for Free

A French start-up founded in 2021, Cognitive Design Systems (CDS) develops software solutions based on artificial intelligence to boost the potential of additive manufacturing. After raising twp million euros in 2023, it is currently offering a campaign for 90 days’ free access to one of its products, Cognitive Additive. This software suite enables analysis of 3D printing process, with features such as orientation strategy definition, automated nesting, automated DfAM analysis, cost and carbon footprint calculation. The aim is to improve design by providing engineers and design departments with the right information.

In the additive manufacturing market, specialized software is becoming increasingly numerous, offering a wide range of functions. Between proprietary software, pure design solutions, those dedicated to part preparation or to automating your production, it’s not always easy to know which tool to choose. That’s where Cognitive Design Systems comes in: the aim is not just to design a part for additive manufacturing, but to have all the cards in hand to make an informed choice, whether in terms of technology, materials, number of parts, etc. Among other things, the company relies on artificial intelligence to make digital simulation easy and designs as optimal as possible.

The software can analyze an assembly or a batch of parts in terms of manufacturability

Cognitive Design Systems Meets the Needs of Manufacturers

Cognitive Design Systems has therefore devised a software suite with three different products to help manufacturers achieve their objectives and solve their problems: how to optimize production costs? How to minimize printing errors? How to automate workflow? Whether it’s choosing the right manufacturing technology or automating the design process, CDS solutions meet the challenges of additive manufacturing as well as those of injection molding and casting.

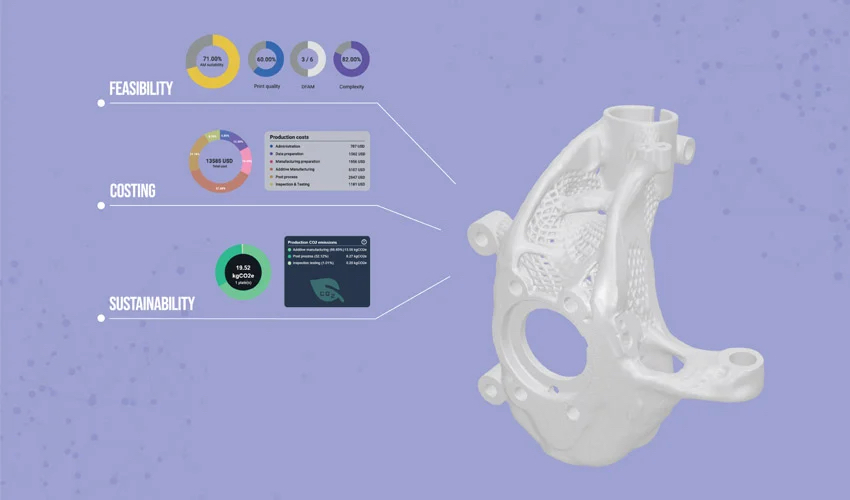

Very often, one of the questions manufacturers ask themselves before taking the plunge into additive manufacturing concerns cost: how do you estimate the cost of 3D printing, and how quickly? Cognitive Screening provides the answer in just 5 minutes. It can analyze an assembly or a batch of parts in terms of manufacturability and production cost.

The solution also responds to environmental issues by calculating in just a few minutes the CO2 emissions of additive manufacturing, and therefore the carbon footprint. To do this, it relies on artificial intelligence to provide key elements that will enable the user to make an informed choice in terms of the preferred manufacturing process and material. For example, Cognitive Screening is able to indicate whether or not a 3D model can be produced using additive manufacturing, thus facilitating the detection of use cases.

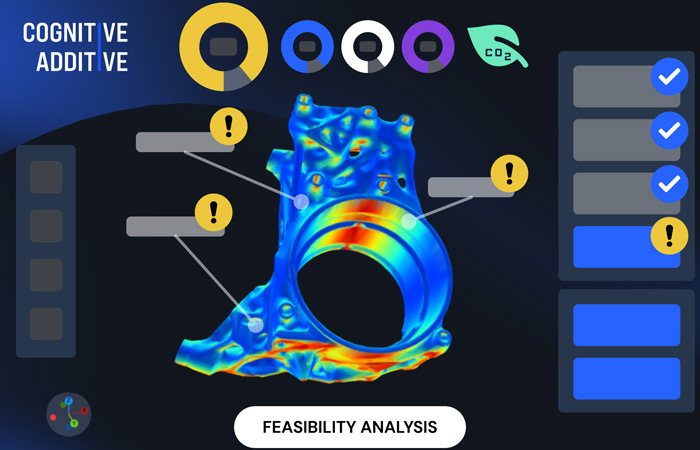

But what about the printing process itself? How do you choose the right part orientation? How do you minimize printing supports? Cognitive Additive offers concrete solutions. It offers a detailed understanding of the entire additive manufacturing process. It will be able to choose the right part orientation, automatically nest parts on your tray to maximize productivity, or carry out a detailed cost analysis. In this way, the user has a clear and precise view of his production process, and can make the right decisions.

In concrete terms, the user loads an STL or STEP file into the software, and in just a few minutes obtains a complete report: analysis of the risks associated with part geometry, the best orientation for printing, creation of print supports, slicing, etc. He also draws up a quotation, giving an idea of the manufacturing cost. He also draws up a quotation, giving an idea of the production cost.

In 5 minutes, Cognitive Additive can estimate the cost of additive manufacturing

Finally, the French company announces the development of a third software package, Cognitive Design, which will be available from November 2024. This will automate DfAM and enable complex designs. The aim is to take modeling for additive manufacturing to the next level, and rely on a powerful tool to boost productivity. Finally, Cognitive Design will enable error-free 3D printing thanks to the capabilities of automated DfAM!

Test the Software Solution Free of Charge for 3 Months!

Cognitive Design Systems is offering a 3-month free trial of Cognitive Additive. The company is launching a 90-day campaign to enable you to discover all the software solution’s features and possibilities.

Georges CASEAU, Sales & Marketing Director at CDS, explains: “Free access to our Cognitive Additive platform will give anyone who wants it a powerful tool for accelerating additive manufacturing workflows and boosting technology adoption. We are convinced that additive manufacturing design is a key stage in the process, as it defines all the production rules and avoids a good number of errors while maximizing productivity.”

One thing is certain, Cognitive Additive will enable you to significantly reduce the time needed to carry out a feasibility study for manufacturing. Interested in this solution? Start your trial now by registering HERE.

What do you think of Cognitive Design Systems’ solutions? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*All Photo Credits: Cognitive Design Systems