Termite Waste Used for Powder-Based 3D Printing Processes

Compared to traditional production methods, additive manufacturing (AM) offers the advantage of producing little or no waste. However, it is no secret that there is still room for improvement for 3D printing in terms of sustainability. In particular, the direct and indirect energy consumption for operation as well as for the production of the materials have an impact on the ecological footprint of the various technologies. For example, the preparation of the printing material for powder-based processes, which are used in particular in metal 3D printing, is also resource- and energy-intensive. It is therefore hardly surprising that more and more projects are dedicated to finding more sustainable filament alternatives. In a recent report by the German Federal Institute for Materials Research and Testing (BAM), which researches the potential of the circular economy for materials science, materials engineering and chemistry, the institute analyzes a recent project to use termite droppings as a 3D printing material.

Photo Credits: Federal Institute for Materials Research and Testing (BAM)

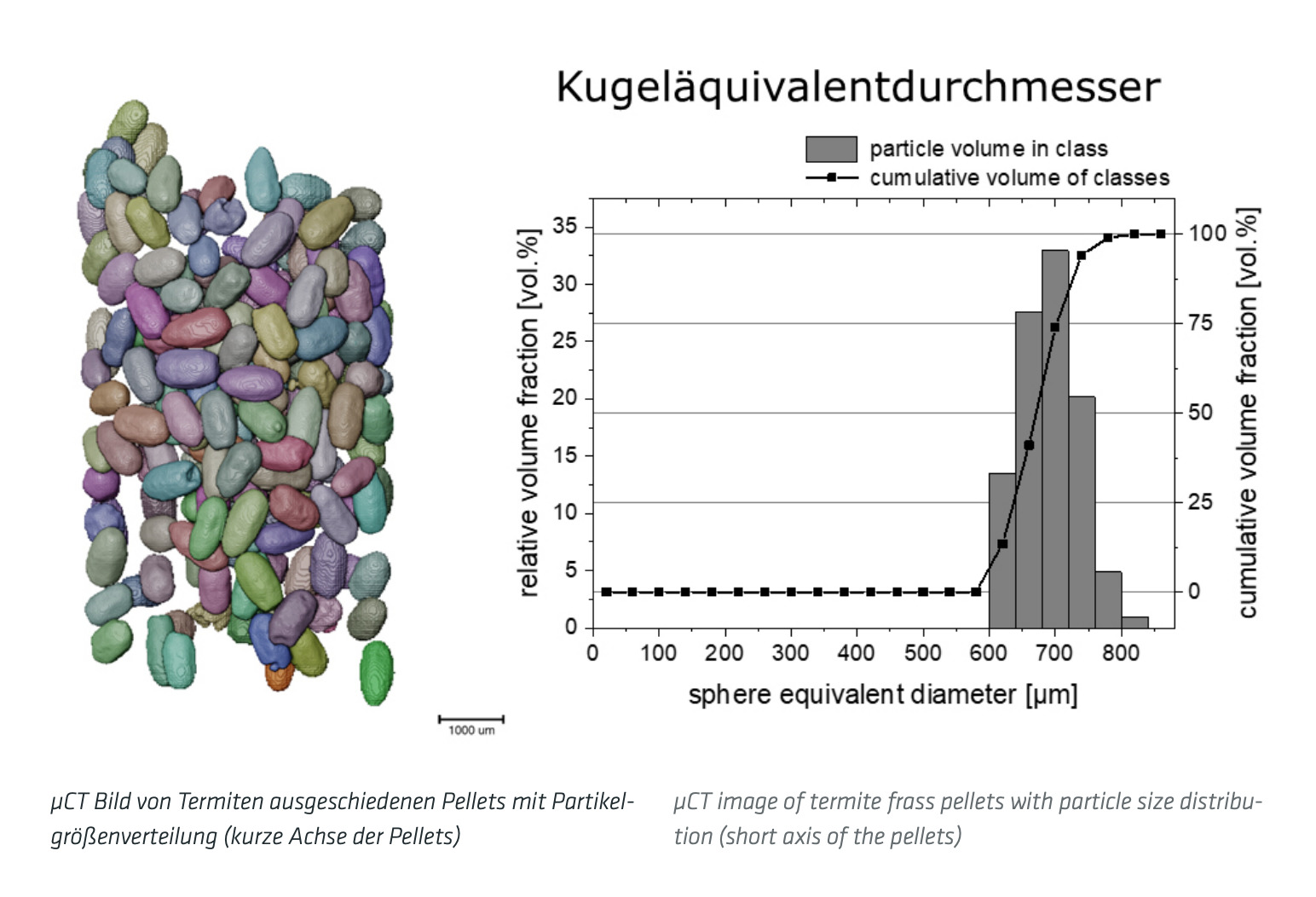

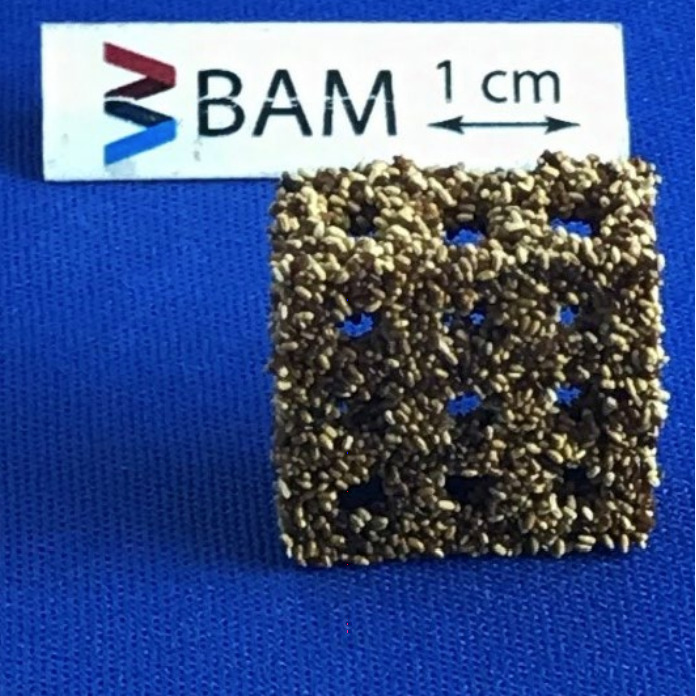

Strictly speaking, this is the excrement of European house borer Hylotrupes bajulus and dry wood termites Incisitermes marginipennis. According to BAM, these droppings consist of small pellets with good flowability, making them suitable for use in powder-baesd 3D printing. In particular, the fact that the droppings are produced in a natural process and can therefore be used as a sustainable source material is of great interest. However, the use of such a natural material source would not only lead to savings in costs and emissions, but can also provide a remedy for the generation of hazardous sources such as fine dust or nanoparticles. These are otherwise often generated in the preparation of the printing material and in the process itself (e.g. metal dust). Because the fine dust remains airborne, it poses a risk to human health.

Photo Credits: BAM

Due to their size, the termite excretions, so-called pellets, do not pose a health risk. With a size of 0.6 – 1mm, the length of these pellets is up to two orders of magnitude larger than the usual printing materials for powder-based processes – but this can even be an advantage for some components. For example, coarser powders enable the production of parts with higher layer thicknesses and thus result in higher build rates. To make the pellets suitable for manufacturing products such as furniture, the parts should then processed with a binder. For the binder, too, the Federal Institute for Materials Research and Testing relies on a natural raw material in the form of tree resins. You can access the complete publication HERE.

In the past, we have already reported on innovations that are helping additive manufacturing to realize its full potential. The issue of sustainability seems to be coming more into focus as the technologies mature. This is also reflected in construction projects and the manufacture of sporting goods. One thing is for sure, the innovation potential of the industry is far from exhausted and we are excited to see what initiatives and material alternatives will surprise us in the future.

What do you think of using termite droppings as a sustainable 3D printing material? Let us know in a comment below or on our Facebook, Twitter and LinkedIn pages! Sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox!

*Thumbnail Photo Credits: BAM