Tailored by Industry: PioCreat’s Blueprint for Smarter 3D Printing

In a market filled with “all-purpose” 3D printers, the Chinese 3D printing solution provider PioCreat is taking a different approach. Its machines are tailored to the specific needs of an industry, from compact dental systems to large-format industrial printers. The result is a portfolio that shows just how versatile additive manufacturing can be when designed with purpose.

Visitors to Formnext will find PioCreat at Booth 12.1 – C02, where the team will showcase its diverse line of printers and invite potential business partners and distributors to explore product demonstrations and collaboration opportunities. Attendees can also arrange a meeting with the team in advance via the company’s website. Before you meet them at the show, explore PioCreat’s product lines below!

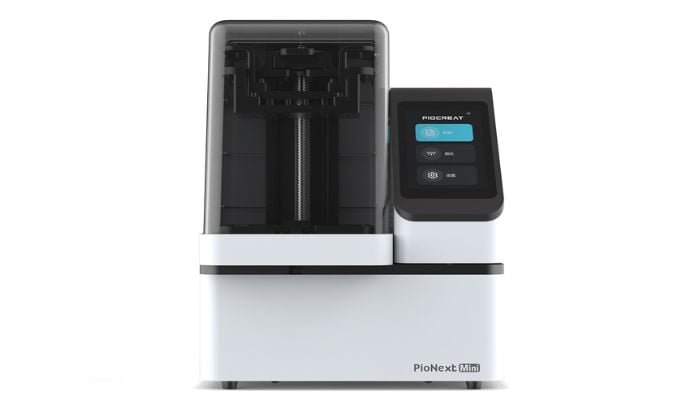

The PioNext Mini

Precision for Dental Professionals

Starting in the dental field, PioCreat has developed technologies that make chairside production faster, more compact, and more intuitive. The PioNext Mini exemplifies this focus on efficiency and portability. With its ultra-compact, suitcase-style design, it enables clinics to produce crowns, bridges, inlays, and veneers directly, saving post time and space. The PioNext mini features a dual resin tank system, which includes an ACF Fast Vat for 10-minute crown printing, and an HDF Clear Vat for polishing-free, high-transparency results. This enables quick material swaps for different applications. Meanwhile, the upgraded LCD screen ensures long-term stability and clarity. Together, these features make it a smart and reliable tool for dental labs and practices looking to streamline operations.

For professionals requiring even greater precision, the DJ89 PLUS, an 8K LCD 3D printer, delivers fine detail and smooth surface finishes ideal for dental applications alike.

Empowering Personalized Medical Care

In healthcare, PioCreat’s 3D printers are designed to bring industrial precision to custom orthotic and prosthetic manufacturing. The MS01 SE stands out as a powerful solution for creating one-piece scoliosis braces, prosthetic sockets, and foot orthoses. With a high-temperature 400°C nozzle, large 650mm build height, and biocompatible material compatibility, it combines strength, comfort, and clinical reliability.

The MS01 SE

The printer’s single-piece printing approach reduces circumferential cracking. And the parts produced by the MS01 SE are strong, too. The model’s Z-axis layer bonding can withstand 10,000 bending cycles without cracking, ensuring long-term durability.

Additionally, the printer’s biocompatibility certifications ensure safe, skin-friendly use. Remarkably, the printer can achieve fast production times, typically between four and seven hours per orthosis, making it a practical tool for busy clinics focused on patient-specific care.

The IPX2 printer, on the other hand, is tailored for producing custom insoles, supporting orthopedists and healthcare providers in delivering precise, comfortable, and durable solutions for their patients. The IPX2 features a specialized TPU extruder that is designed to ensure smoother, more stable extrusion, as well as a dual-station design, which means users can print a pair of adult insoles in one go. One of the best parts? It only takes about an hour, without sacrificing precision.

The IPX2

Power and Performance for Industrial Users

Moving to industrial applications, PioCreat’s G5Ultra Pellet 3D Printer demonstrates the company’s commitment to high-speed, high-temperature performance. This machine supports thermoplastic pellets as feedstock, an economical and sustainable option for high performance and material flexibility.

The nozzle can be heated up to 420°C, and the print bed up to 120°C. With its segmented extruder, the G5Ultra offers outstanding material compatibility, handling composites such as PA-CF, PLA, PETG-GF, ABS and more. Whether in research labs, design studios, or educational institutions, the G5Ultra provides a robust platform for experimentation and innovation.

The G5Ultra

Accessible Innovation for Every User

Finally, PioCreat is also reaching makers and professionals with the HALOT-X1 Combo, a 16k resin 3D printer that blends simplicity with precision. Arriving fully calibrated and leveling-free, it is ready to print straight out of the box.

Its top-down motion system delivers enhanced layer consistency, while 92 independent light zones intelligently expose only the needed areas and guide optimal model placement to reduce overexposure and extend the screen’s lifespan. Combined with a quick-release build plate that allows models to be removed with a simple twist, eliminating the risk of scratches or damage to delicate prints, the HALOT X1 makes high-quality resin printing both accessible and enjoyable for hobbyists and professionals alike.

The Halot-X1 Combo

Discover PioCreat at Formnext 2025

Across every industry it touches, PioCreat proves that 3D printing can be both specialized and versatile. Whether you’re in dental care, medical manufacturing, industrial production, or education, there’s a solution designed with your needs in mind. Visit PioCreat at Booth 12.1 – C02 to see their full lineup in action, experience live demonstrations, and explore partnership opportunities with a company that defines what tailored 3D printing can achieve. To learn more about PioCreat, visit their website here.

What do you think of PioCreat? Let us know in the comments or on our LinkedIn or Facebook pages! Plus, don’t forget to sign up for our free weekly Newsletter to get the latest 3D printing news straight to your inbox. You can also find all our videos on our YouTube channel.

*All Photo Credits: PioCreat