Systemic Bio Accelerates Drug Development in 3D Using Hydrogels and Human Cells

3DN: Can you introduce yourself and tell us about your connection to 3D printing?

Taci Pereira (Right)

3DN: What is Systemic Bio? How did the idea to start the company come about?

Systemic Bio is a subsidiary of 3D Systems created to apply its industrial bioprinting technology to drug discovery and development. While 3D bioprinting is often associated with regenerative medicine or implantable tissues, it also has tremendous potential to improve how we study diseases and develop new therapies by testing them in functional human tissue models.

The idea for Systemic Bio emerged in 2018 when I observed the rise of AI and machine learning in biotechnology, particularly in companies like Insitro. I admired Daphne Koller’s work and closely followed how computational tools were being applied to biology. But I noticed a major gap: AI models are only as good as the data they are trained on. If we rely on preclinical models that often fail to predict human outcomes, AI will only accelerate failures. This can save time, but it doesn’t solve the underlying problem.

That’s when I had the idea to create an in silico platform based on human-relevant data from 3D bioprinted tissues. To do this, I needed scalable and reproducible bioprinting technology, which didn’t yet exist. Through the acquisition of Allevi, I gained access to 3D Systems’ decades of experience in high-throughput additive manufacturing. We then founded Systemic Bio in August 2022 with $15 million in funding to produce large-scale bioprinted tissues and generate data that enables better decision-making in drug development.

3DN: Can you tell us more about the 3D bioprinting technology used by Systemic Bio?

3DN: What are the advantages of additive manufacturing for drug discovery and development?

3DN: How do you see the future of 3D printing in the medical field?

Bioprinting is poised to transform medicine in multiple ways. In the near term, we are entering the era of tissue therapy, a new class of treatments where, instead of designing an entire organ, we can bioprint functional tissue constructs that enhance or support organ function. These tissues are easier to produce, can be tailored for specific applications, and can also serve as advanced drug delivery systems.

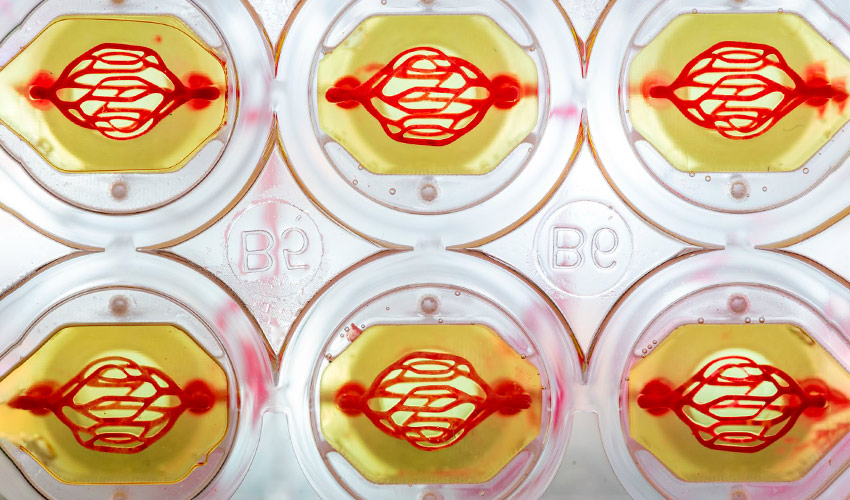

At Systemic Bio, our goal is to bioprint millions of vascularized tissues that can be used to generate computational models of human organs and systems. These tissues form the basis of large-scale datasets, which are libraries of different therapeutic modalities tested across various tissue types and biological contexts. By labeling each tissue response with key therapy attributes such as structure, dose, and mechanism of action, we can train AI and machine learning models to predict safety and efficacy in multiple use cases, including liver toxicity, cardiac safety, or tumor response.

Imagine being able to introduce a new therapy into this system and obtain an organ-by-organ safety profile along with disease-specific efficacy predictions, all based on human-relevant data. That is the future we are working toward. We want to create human-based predictive models that can dramatically accelerate drug development and reduce drug-related risks.

In the longer term, the field continues to pursue its most ambitious goal: bioprinting fully functional transplantable organs. We are finally entering an era where key factors are aligning, including industrial-scale bioprinting, advanced automation, and regulatory support from the FDA for alternatives to animal testing. Achieving this future requires continued focus on reproducibility, scalability, and clinically meaningful validation. If we succeed, bioprinting will not just complement medicine; it will redefine it.

The Systemic Bio team

The article has very interesting content.