A Sustainable Nanocellulose-Based Material Has Been Developed for Construction 3D Printing

Sustainable materials are increasingly in the spotlight as both companies and research teams try to find more eco-friendly alternatives for different industries. One of the sectors that places most emphasis on this quest for sustainability is the construction industry. This is because the emissions of this sector alone are some of the highest worldwide. Annually, the construction sector consumes 50% of the total global fossil resources consumed in the world, generates 40% of all global waste, and causes 39% of global CO2 emissions. This is why the search for an environmentally friendly material for construction has been so important. Now, it could be a reality with a 3D printed hydrogel that could be a greener, architectural material.

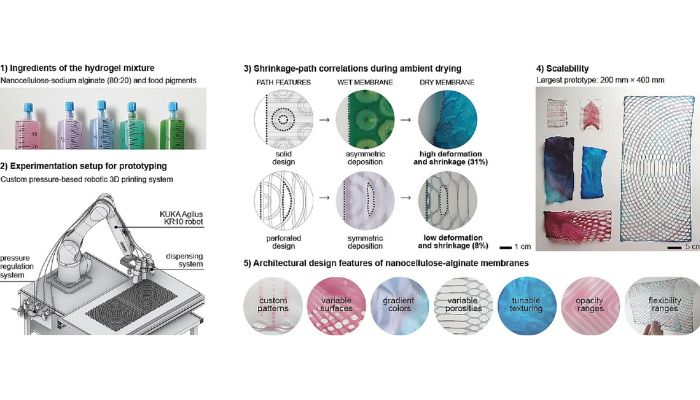

The new material for more eco-friendly construction comes from a team of researchers from Chalmers University of Technology in Sweden and the Wallenberg Wood Science Center. More specifically, the material is a 3D printed hydrogel made of nanocellulose and algae. Nanocelluolose, for those who may be less aware of it, is a well-known biomaterial and is already extensively used in the field of biomedicine as a way to 3D print scaffolds for tissue and cell growth. However, this would mark the first time it was used in architecture.

The univeristy where they have developed this 3D printed sustainable hydrogel material made out of nanocellulose for construction

To use the material, it must be dried, made possible thanks to the addition of a third material to the original mixture of nanocellulose and water. Alginate, a material composed of algae, was the key to developing the hydrogel, as it gave the dried mixture the flexibility it needed to be used as a building material

The author of the Chalmers University of Technology study conducted by this research team, Malgorzata Zboinska, explained: “For the first time we have explored an architectural application of nanocellulose hydrogel. Specifically, we provided the so far missing knowledge on its design-related features, and showcased, with the help of our samples and prototypes, the tuneability of these features through custom digital design and robotic 3D printing.”

The nanocellulose used in the hydrogel can be sustainably sourced from multiple locations in nature and is a clearalternative to plastic. For within the eco-friendly materials that can stand up to plastic, nanocellulose is the most abundant. “The nanocellulose used in this study can be acquired from forestry, agriculture, paper mills and straw residues from agriculture. It is a very abundant material in that sense,” commented Malgorzata Zboinska.

She added: “3D printing is a very resource efficient technique. It allows us to make products without other things such as dies and casting forms, so there is less waste material. It is also very energy efficient. The robotic 3D printing system we employ does not use heat, just air pressure. This saves a lot of energy as we are only working at room temperature.”

Photos taken from the study conducted by Malgorzata A. Zboinska.

The main uses of the material range from partitions, blinds or panels, to wall coverings for buildings or tile cladding. And though right now the future of this material is uncertain, it is certainly also promising. You can learn more in the study HERE.

What do you think of the development of this new 3D printed hydrogel material for more sustainable construction? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*All Photo Credits: Chalmers University of Technology