Sustainable Design in 3D: Thrōn Made’s Vision for the Future of Furniture

As additive manufacturing continues to push the boundaries of design and production, one area where its potential truly shines is in furniture making. Combining form, function, and sustainability, 3D printed furniture is opening new doors for designers to experiment with complex geometries, eco-friendly materials, and innovative production methods that traditional manufacturing often can’t match.

Thrōn Made, a young and ambitious brand founded by Sam and Jared Wesenick, is at the forefront of this movement. Based in Schofield, Wisconsin, United States, they describe themselves as “a true startup without large corporate funding delivering a set of 3D printed furniture to grow a community.” What began as a way to showcase the capabilities of industrial 3D printing technology has evolved into a creative venture that blends craftsmanship with cutting-edge innovation. From biodegradable materials to intricate, functional designs, Thrōn Made’s approach embodies the future of sustainable furniture. We spoke with Sam Wesenick to learn more about the story behind Thrōn Made, their unique design process, and how 3D printing is reshaping what’s possible in modern furniture design.

3DN: Could you introduce yourself and tell us the story behind Thrōn Made?

Sam Wesenick (left) and Jared Wesenick (right) are behind the Thrōn made project.

My name is Sam Wesenick, and I’m working with Jared Wesenick to bring this project to life. The story behind Thrōn made began in 2019, when Jared was looking for a way to promote the capabilities of the Compound Dynamics RM30 3D Printer. He designed and printed the CD Lounge chair and took it to a few trade shows. People really liked what they saw! This year, because we had printer time to fill on one of our in-house printers, we decided to launch the brand Thrōn made, offering furniture that blends functionality and sustainability with unique aesthetics.

3DN: Can you walk us through your design process for 3D printed furniture?

Our design process for 3D printed furniture begins with plenty of ideas, whether we saw traditional furniture that inspired us, or just started scratching an idea on notebook paper. We then model it in CAD software to cement the idea and create a file we can print with. Next, we test miniature models by printing them on one of our desktop printers, and then we stack weight on top of them to see if they are structurally sound. Then we print at full scale. Usually, adjustments at this point are just for comfortability. We make adjustments based on feedback before finalizing the piece for production.

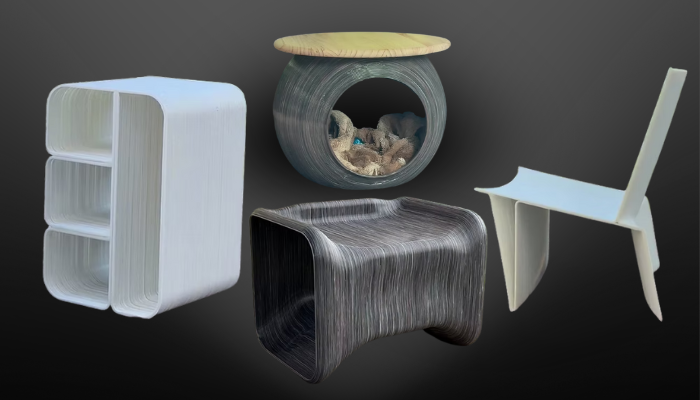

Some examples from their current collection include the Minima Shelf (left), Laakito Chair (center bottom), Mascota Cat Home (center top), and Bergsto Chair (right).

3DN: What inspired you to choose 3D printing over traditional manufacturing methods, and what unique opportunities does it provide?

We chose 3D printing over traditional methods because the furniture that is produced is something that is relatively new and exciting, and that pumps us up. This technology enables us to experiment with complex shapes that would be costly or impossible with woodworking or molding, and it is also the area where our skills excel the most. On top of that, 3D printing aligns with our goal of innovative sustainable manufacturing.

3DN: What 3D printing technologies and materials do you use, and how do they influence the final look, feel, and durability?

Although we don’t want to get too specific, we use a plant-based biodegradable plastic that starts as pellets, and is clear and smooth. From there, we add one or two colorants to get any look we want. We’ve done a lot of material and machine testing, and we have found that we can print this material in large beads that feel smooth while staying very strong.

The biodegradable plastic pellets are used in the filament that creates each piece.

3DN: Sustainability is a big topic in design today. How do you incorporate sustainable practices and materials into your work?

On top of using plant-based plastic, as opposed to plastic from fossil fuels, we also offer a recycled option which uses 15% recycled material that gives each piece a cool grayish rainbow-like appearance. Doing this helps keep plastic out of landfills without compromising quality. It’s possible to print with a combination of materials and recycled materials because we use pellet extrusion, also called fused granulate fabrication (FGF), instead of traditional filament used for desktop applications. This method also allows us to extrude ten times the amount of material in a given time period, meaning that the machine is running far less than a desktop machine would, decreasing energy use.

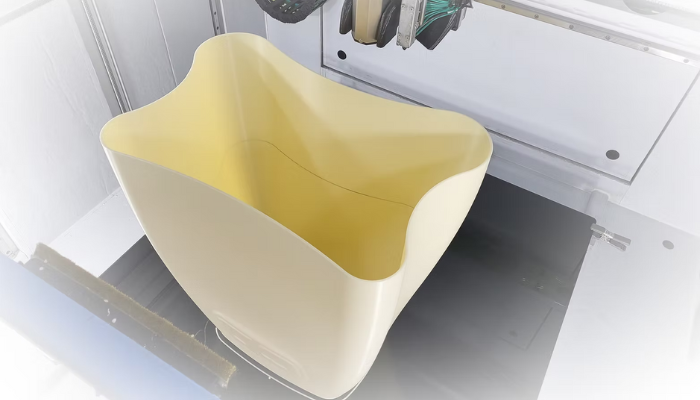

An example of the current printing process.

3DN: Do you have any final thoughts for our readers?

Thrōn made is a small project with big ideas. We are learning as we go, but we are passionate about experimenting with new ways to make beautiful furniture. Lately, we have been drawn to combining 3D printing with more traditional methods to create pieces that feel fresh but still grounded. If any of this speaks to you, we would love your support on our Kickstarter page HERE. Thank you!

What do you think of Thrōn Made’s vision? Let us know in a comment below or on our LinkedIn or Facebook pages! Plus, don’t forget to sign up for our free weekly Newsletter to get the latest 3D printing news straight to your inbox. You can also find all our videos on our YouTube channel.

*All Photo Credits: Thrōn Made

short, sharp, and actually kinda inspiring. Love the blend of creativity and tech vibes.

What I am concerned about is the cost of manufacturing products using 3D technology. Will they be mass produced at

I appreciate the focus on sustainable design.

But I wanted to share my concern regarding quality, based on the image used “An example of the current printing process”.

The visible line inside the printed part seams like layer separation or a defect, which raise doubts about the quality of the design, machine, material, ++ .

Even if it’s not an actual defect, the visual impression is bad,.

Earning AoC gold efficiently requires smart farming, resource gathering, and understanding the in-game economy.