Researchers Create a Superior Titanium Alloy Using Laser Powder Bed Fusion

Scientists from the City University of Hong Kong (CityU) have made a breakthrough in the design of a titanium alloy. Thanks to additive manufacturing (AM), they were able to successfully create an alloy with superior mechanical qualities. The project arose from modeling showing that though it is generally thought that increased uniformity in alloy components is ideal in order to prevent brittleness, in fact a certain degree of heterogeneity (diversity) could actually create unique microstructures that enhance the alloy’s properties. Based on this idea and using laser powder bed fusion along with stainless steel and titanium alloy powders, the scientists managed to create an alloy that was both stronger and lighter.

The research team, lead by Professor Chain-Tsuan Lieu of CityU’s Hong Kong Institute for Advanced Study (HKIAS), published a paper in the journal Science “In situ design of advanced titanium alloy with concentration modulations by additive manufacturing” wherein they outlined their findings. Namely, that though AM is most often considered for its advantages when it comes to geometric possibilities for design of parts, in this case the team explored how it could be used to not just use materials but also design them with better properties.

The Lava-like microstructure in the 3D-printed titanium alloy (Photo Credits: Credit: Dr Zhang Tianlong /DOI number: 10.1126/science.abj3770)

Or as Dr. Tianlong Zhang, a postdoc in the Department of Materials Science and Engineering (MSE) at CityU and one of the authors of the paper, explained, “The unique features of additive manufacturing provide us with a greater freedom in designing microstructures. Specifically, we have developed a partial homogenisation method to produce alloys with micrometer-scale concentration gradients with the aid of 3D printing, which is unachievable by any conventional methods of material manufacturing.”

How did they do it?

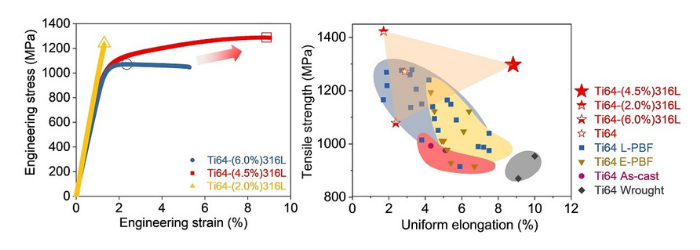

In essence, the process involved melting and mixing two different alloys, for example titanium alloy powders and stainless steel powders, using laser powder bed fusion (L-PBF). Or more specifically, they used Ti-6Al-4V (a titanium alloy) and a small amount of 316L stainless steel to produce micrometer-scale concentration modulations of the stainless steel elements within the titanium alloy. This helped lead to a transformation of the material giving it a higher tensile strength with uniform elongation and an excellent work-hardening capacity.

The results showed that the resulting alloy had superior mechanical properties (photo credits: Dr Zhang Tianlong /DOI number: 10.1126/science.abj3770)

The team controlled certain printing parameters, such as laser power and scanning speed which allowed them to create the non-uniform composition of the elements but in a more controllable way.The resulting alloy certainly could be called a success. It is not just 40% lighter than traditional stainless steel while still exhibiting incredible strength. If you want to learn more, you can buy the study HERE or read the press release from CityU HERE.

What do you think of this titanium alloy? Let us know in a comment below or on our Linkedin, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*Cover Photo Credits: City University of Hong Kong