Style2Fab: MIT’s AI-Driven 3D Printing Aid

Over the years, the 3D printing community has been made up of passionate individuals who have dedicated a lot of blood, sweat and tears towards building communities of makers. All this in order to be able to share each other’s expertise and precision, notably working towards tuning the 3D rendering, slicing and printing phases. With companies trying to attract new users and the seemingly limitless potential offered by new technologies such as ChatGPT, the bar to entry into 3D printing has never been lower for the uninitiated. To help further simplify the process, researchers at MIT have developed an AI-driven tool that makes it easy to customize and print 3D models.

Known as Style2Fab, the program is built around a generative artificial intelligence program. It uses deep-learning algorithms to assist users without requiring them to know the technical specifications required to customize and print 3D models. The program is not only for aiding new users, as the research team at MIT noted, the program will help experienced makers speed up their workflow and provide an even finer point of control.

In order to get a better understanding of how an AI could work with a user on a 3D printing project, the researchers studied the catalogs of online STL file-sharing websites such as Thingiverse. By looking at the different printable objects available online, the team could start to see how AI could analyze and break down complex digital models and better understand the functionalities within the structure of the 3D models themselves.

An AI Tool to Reduce Barriers in 3D Printing

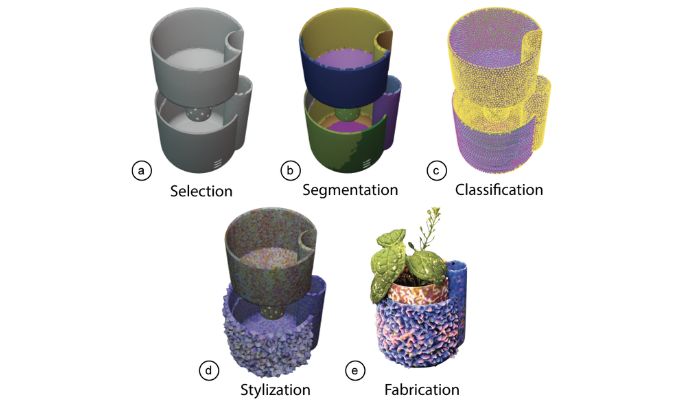

“We quickly saw that the purpose of a 3D model is very context dependent, like a vase that could be sitting flat on a table or hung from the ceiling with string. So it can’t just be an AI that decides which part of the object is functional. We need a human in the loop,” explains Faraz Faruqi, computer science student and member of the MIT research team. To answer the question of functionality, the team broke down the parts of the model into two functional classifications: external (aesthetic) functionality, which faces outwards and interacts with the external environment, and internal (functional) functionality, which concerns the structural parts of the model that connect together.

Once these two classifications are created, it’s up to a human user to accept the AI’s segmentation. “[It] is a really hard problem to classify segments just based on geometry, due to the huge variations in models that have been shared. So these segments are an initial set of recommendations that are shown to the user, who can very easily change the classification of any segment to aesthetic or functional,” Faruqi continues. After the segments are specified and confirmed, the user is able to enter prompts with another AI system, Text2Mesh, which can map out the shape and texture of the desired 3D model that is ready for printing.

The team hopes to continue working towards fine-tuning the system for more accurate shapes, as well as generating original 3D models from scratch. They are also eagerly looking towards possible use in the medical industry, where healthcare professionals and patients with little experience with 3D printing could easily create items such as splints or casts with the help of an AI program. Their research will be presented at the upcoming ACM Symposium on User Interface Software and Technology, and for more information, you can read more HERE.

The AI program allows the user to select the classification of different object parts and the styling choice of the material with minimal knowledge requirements (Photo credits: Faraz Faruqi and Stefanie Mueller)

What do you think about this AI-driven 3D printing software? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*Cover Photo Credits: Faraz Faruqi and Stefanie Mueller