Stewart-Haas Racing Partners with 3D Systems for Enhanced Mustang Dark Horse

Stewart-Haas Racing has continually sought innovative methods to enhance their vehicles’ performance in the highly competitive NASCAR series. In line with the emerging trend of leveraging additive manufacturing within motorsports, Stewart-Haas Racing has announced their collaboratation with 3D Systems to enhance the aerodynamic performance of the new 2024 NASCAR Ford Mustang Dark Horse. Utilizing advanced 3D printing technology, the partnership has enabled efficient, cost-effective testing of numerous body panel shapes, streamlining the development process.

The aerodynamic engineering team at Stewart-Haas Racing faced the task of testing hundreds of different body panel shapes to pinpoint the most aerodynamically efficient design while adhering to NASCAR’s stringent aerodynamic requirements. Traditionally, achieving NASCAR approval involves extensive full-scale wind tunnel testing, a time-consuming and expensive process. The challenge for SHR was to find a way to test numerous designs efficiently within these constraints.

(Photo Credits: 3D Systems)

The collaboration with 3D Systems provided a novel solution for Stewart-Haas Racing – a potent combination of Stereolithography 3D printers and 3D Sprint software from 3D Systems. This technology enabled the rapid production of precise, full-scale body panels that could be assembled quickly onto the car for wind tunnel testing.

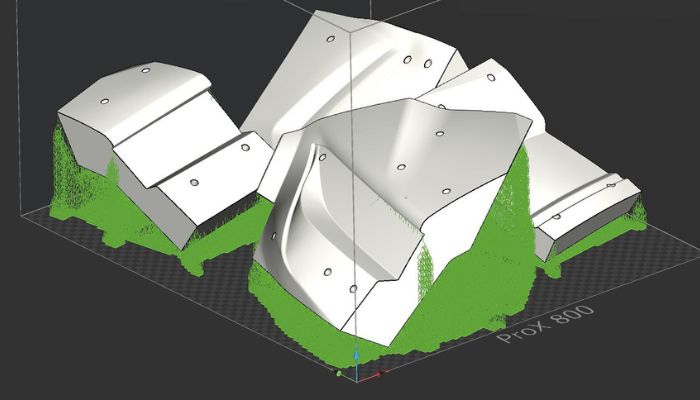

Following extensive development and testing by SHR’s Computational Fluid Dynamics team using CAD software and a virtual wind tunnel, the most promising body panel designs were chosen. These designs were then 3D printed using the 3D Sprint software, a process facilitated by the precision and reliability of the ProX 800 SLA machine. The result was a series of high-caliber body panel prints with smooth surfaces, optimized for enhanced aerodynamics.

These 3D printed panels were then fixed onto the car’s substructure, creating a full-scale, realistic model for wind tunnel testing. This approach allowed for easy addition and removal of body panels to test a wide range of aerodynamic concepts. With each test run, engineers were able to adapt their prototypes and increasingly refine the car’s body shape to move closer to meeting NASCAR standards. This process was repeated over several months until the final design was achieved. Once approved, the design was used to create carbon-fiber body panels for the 2024 racing season.

(Photo Credits: 3D Systems)

The result is a final race car body design that successfully combines the sleek aesthetics of the Ford Mustang Dark Horse with the advanced aerodynamic features needed for competitive racing. The ability to rapidly prototype and test multiple design variations has set a significant new standard in the industry, and is projected to further propel the use of 3D printing in motorsports, especially as other racing teams seek to gain a competitive edge in NASCAR.

What do you think of this collaboration between Stewart-Haas Racing and 3D Systems? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly newsletter here for the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*Cover Photo Credits: NASCAR