The use of steel in additive manufacturing is increasing according to SmarTech Analysis

SmarTech Analysis has just published a new study, this time on the steel and additive manufacturing market. This metal is believed to be the most widely used in 3D printing: the number of deliveries in powdered steel grew by 48% in 2018, according to the report. With interesting mechanical characteristics for industries such as aerospace or automotive, it is not surprising to witness this increase – it remains to be seen why it is outperforming metals such as titanium or aluminium. SmarTech Analysis therefore looked at the main factors of this growth, the industry users, prices and opportunities offered.

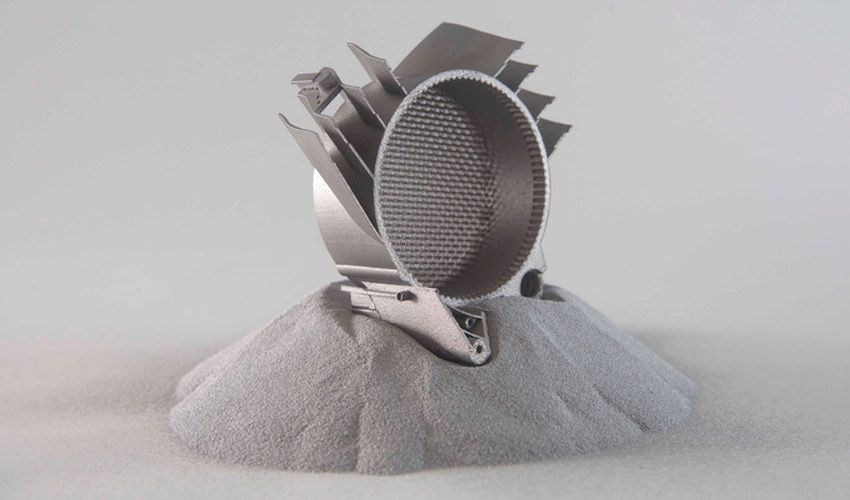

Steel is a metal alloy, made of iron and carbon, which has very interesting mechanical properties, including elastic deformation, breaking and impact resistance and elevated strength. Its mechanical strength depends on its carbon dosage. Available in several forms, steel is also a powder compatible with additive manufacturing solutions, such as SLS or DMLS. Compared to other metals in the 3D printing market, steel is more accessible and can be used under different types of alloys, making it even more attractive for industries with their own requirements.

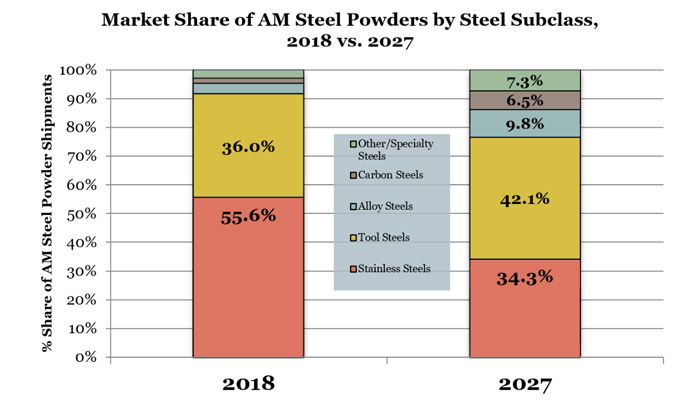

Source: SmarTech Analysis

In its new report, SmarTech Analysis examined the market share of each steel subcategory available in the additive manufacturing market. The results show that tool steel is expected to grow the most – it is expected to represent a market share of 42.1% in 2027 compared to 36% in 2018. Stainless steels should see their market share fall. According to SmarTech’s analyses, there are only about ten primary steel alloys that are widely printed today; however, the study reveals that some players are beginning to develop new steel materials, leading to new opportunities for the additive manufacturing market.

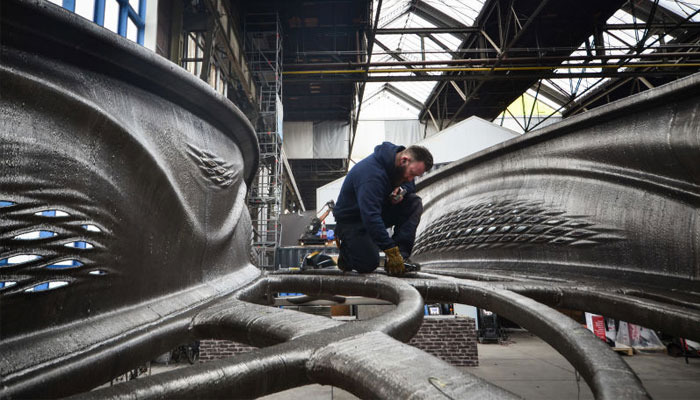

Finally, the report reveals that the use of steel for the manufacture of final parts is developing mainly in sectors that are not part of the main historical markets for metal additive manufacturing, namely the medical and aerospace sectors. These two markets obviously use steel, but steel use should grow from all the other industries that are increasingly using 3D metal printing. For example, we reported on the MX3D bridge 3D printed from steel in April last year.

MX3D bridge | Photo credits: Adriaan de Groot

You can find more information on SmarTech’s website HERE. Let us know your thoughts in a comment below or on our Facebook and Twitter pages! Sign up for our free weekly Newsletter, all the latest news in 3D printing straight to your inbox!