Steakholder Foods Talks 3D Printed Meat Alternatives

Over the past few years, there has been a growing interest in additive manufacturing in the food industry. The evolution of 3D printing has brought about a radical transformation in food production methods, offering the added bonus of being able to customize products to meet specific consumer needs. An example of this trend is illustrated by Steakholder Foods.

This Israeli company, founded in 2019, sets itself apart by offering plant-based alternatives for products such as shrimp, eel, fish fillets and meat. Their aim is to maintain the same taste and texture as the original products, while meeting the demands of consumers looking for more sustainable food choices. Their goal is to produce food with a low environmental impact, while playing a key role in reducing animal suffering. To find out more, we caught up with Tzahi Seger, the company’s Digital Marketing Manager.

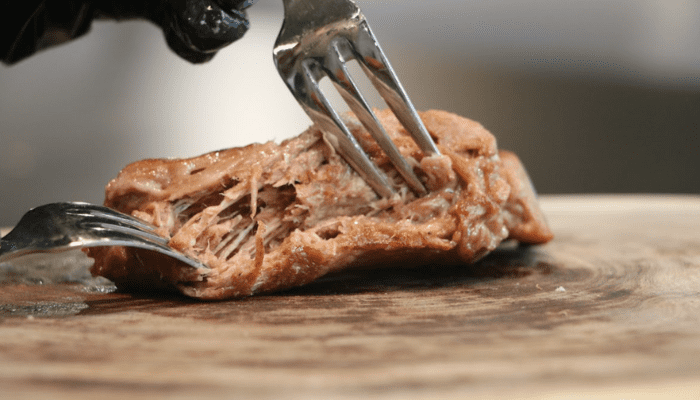

An example of a 3D printed meat alternative from Steakholder Foods

3DN: Could you introduce Steakholder Foods and your connection with additive manufacturing?

Steakholder Foods is building the industry-standard machinery, software and printing materials to help accelerate the plant-based and cultivated food industries and bring them to full capacity. The company offers its proprietary 3D printers, printing ink, operating software, and ongoing services to help manufacturers of all sizes reach the execution of their offerings.

Using its variety of manufacturing technologies and services, Steakholder Foods offers manufacturers the ability to produce plant-based food that closely mimic traditional meat’s taste, texture, and appearance— as an alternative to industrialized farming and fishing. Our expertise lies in creating plant-based meat and seafood products with complex textures. But while our initial focus is on plant-based options, we’re developing cultivated cells for seamless integration with an eye on the future.

3DN: How does your 3D food printing process work (technology, materials used)?

Our printing technology is a game-changer in food manufacturing, offering a spectrum of technical advantages. We employ layered printing to strategically combine diverse materials within a single product, enabling the creation of intricate structures and textures, something challenging with traditional methods. Fiber alignment mimics the texture of real meat, enhancing plant-based products’ meat-like qualities. Our technology allows for the integration of additional processes, such as cross-linking and the addition of fats, further improving product quality. The level of customization and precision is unparalleled, catering to specific consumer demands and dietary needs.

More specifically, the food 3D printing process at Steakholder Foods involves a combination of food printing technology and culinary science. The process typically starts with the preparation of inks, which are made from proteins and other elements that mimic the properties of real meat. These inks are then loaded into a 3D printer, which precisely deposits them layer by layer to build the desired meat structure. The technology allows for fine control over the texture and structure, enabling the creation of products that closely resemble traditional meat in terms of taste and texture.

3DN: What foods can Steakholder Foods print today?

Currently, Steakholder Foods can print a variety of meat products, such as plant-based beef steaks, fish fillets, eel and shrimps. These products are designed to replicate the taste, texture, and nutritional content of conventional meat. Looking towards the future, the company aims to expand its range to include chicken fillet. There is also ongoing research to reduce the cost of cultivated meat, and in the future the plant-based material will be used as the platform for the cultivated biomass.

3DN: What potential challenges do you face in integrating food 3D printing?

Some challenges in integrating 3D food printing include scaling the technology for mass production while still ensuring consistency and quality in the printed products. Additionally, there’s the challenge of public perception and acceptance, as introducing a printed food technology often requires extensive consumer education and marketing efforts.

3DN: What advantages do you think 3D printing brings to the food sector?

3D-printed meat represents a revolutionary step in sustainable food production. By utilizing advanced printing technologies, we’re able to significantly reduce environmental impact, minimize animal welfare concerns, and enhance food security. Our process mirrors the texture and taste of traditional meat, promising a future where ethical, eco-friendly, and secure meat production is accessible globally. With the flexibility to place these printers anywhere in the world, we can contribute to feeding populations in even the most remote regions.

3DN: Any last words for our readers?

As the world grapples with the challenges of sustainable food production and ethical meat consumption, technologies like 3D food printing present a promising solution. Companies like Steakholder Foods are at the vanguard of this revolution, offering innovative approaches to meat production that could significantly impact our food systems. It’s an exciting time in the food industry, and the potential for positive change is immense. You can find out more on our website HERE.

What do you think of Steakholder Foods? Would you eat their 3D printed meat alternatives? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*All Photo Credits: Steakholder Foods

Sono convinto della grande opportunità e che un’azienda come la vostra abbia una potenzialità di crescere in modo esponenziale per il bene pubblico.

Grazie