#Startup3D: SelectAM Helps Companies Identify the Right Parts to 3D Print

Additive manufacturing (AM) is increasingly being used to produce final parts, yet many companies still resist adopting the technology. It can be difficult to transition from prototyping to small or even large batch production, especially if a company lacks AM expertise. This often results in improper investments and losses that, as a result, discourage companies from investing in AM. To address these issues and make the technology more accessible, Finnish startup SelectAM has devised a fully automated, AI-based platform capable of identifying the most appropriate parts to 3D print. Based on some provided data, SelectAM estimates costs, production time and savings compared to using traditional techniques. To find out more, we interviewed the SelectAM team and learned about how their solution works, current projects and the potential of artificial intelligence in the 3D printing industry.

3DN: Could you introduce yourself and your connection to 3D printing?

Niklas: My name is Niklas Kretzschmar, and I am a co-founder and the managing director of SelectAM. The first time I got in touch with 3D printing was back in my days as a mechanical engineering student, being impressed by the design possibilities 3D printing provides, not just for prototypes, but especially for more functional production products. Initially, I have been working on decision support systems for metal powder bed fusion and on an ontology for industrial 3D printing knowledge.

Kalle: My name is Kalle Lepola and I’ve been an additive manufacturing addict for almost eight years. I started with HP and the MJF technology back in 2017, did a quick detour at SAP with enterprise software, and eventually missed the AM industry so much that I joined SelectAM as an advisor and later as their Chief Business Officer. Initially, I became interested in this industry as it promises a greener and faster method for manufacturing, reducing the need for logistics and warehousing. Also, I’m looking forward to the day that I can 3D print myself a new ligament for my bad knee.

Niklas Kretzschmar (left) and Kalle Lepola (right)

3DN: What is SelectAM’s mission?

Our core mission is to help companies make the right parts for the right reasons. We make digital manufacturing accessible, enabling companies to benefit from efficient and sustainable processes that reduce waste and prioritize targeted products from design to delivery.

In previous job positions, we noticed major problems within the AM industry that were preventing companies from accessing the benefits and promise of additive manufacturing. Companies still rely on a few “experts” to identify and qualify parts for additive manufacturing. Most often, the selection of parts to be 3D printed is based on gut feelings and knowledge of a few manufacturing techniques.

Second, identifying and qualifying the most efficient production method for a given part is now a manual and time-consuming process for many companies. Finally, major problems in the manufacturing industry include overstocking of products (due to high minimum order quantities) and long and vulnerable supply chains.

What we do, fundamentally, is provide companies with an “automated 3D printing expert” available 24/7 so that they can make data-driven, bias-free choices based on broad knowledge and not limited to a handful of manufacturing technologies.

3DN: Could you explain how the SelectAM online platform works?

There are many use cases for our platform, so we’ll briefly talk through them.

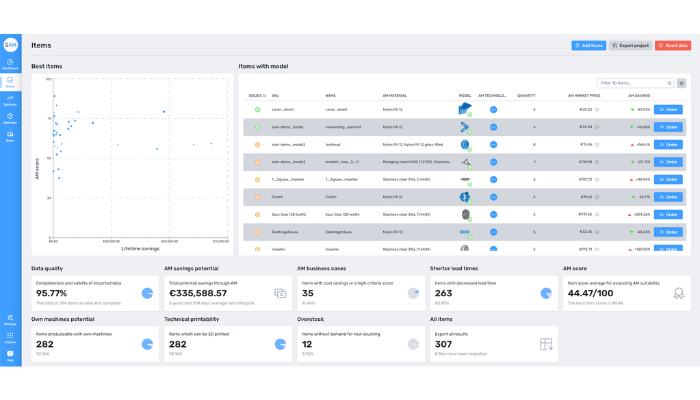

- Top-down identifying – Companies use our solution to identify, through data from their ERP/PDM/PLM/Data Lake solutions, which parts should be made additively, which should be redesigned, and which should still be produced by conventional methods. In this approach, we take into consideration many supply chain parameters like MOQ (Minimum Order Quantity), remaining service lifetimes, yearly demands, current stock, and many more to eventually calculate a total cost of ownership cost that we simulate against AM cost. With this capability, we enable our customers to holistically assess how AM would fit their operations, and we’ve seen a maximum of five percent share of components identified along with a 90 percent reduction in the time it takes to make such decisions when analyzing more than just single parts.

- Price check and ordering – Our solution, and particularly its free tier, is used for library screening to obtain real-time market prices for cost-per-piece determination for AM component procurement. This functionality is really the heart of the solution and we wanted to make it free for everyone. The good thing is that this evaluation can be done with and without CAD files, still providing accurate results. In the end, if among different manufacturing technologies 3D printing has proven to be more cost-effective, we also make it possible to order parts.

- Quotations – We also collaborate with 3D printing service providers and internal teams of large OEMs to accurately estimate cost and time for production and post-processing. With this capability, our customers can generate quotes for their machines in seconds. We have seen automation rates of 40-60%, which would mean that one full-time employee could be deployed on more strategic tasks or sell twice as much if capacity allows.

- Re-design estimates – When you investigate your part libraries, most likely only 2-5% of the components are directly good fits for additive. This is understandable as most of the products in your supply chain have not been designed for AM. This percentage can be increased by re-designing the components. Our re-design estimates give our customers the ability to assess the economics for their components after re-design, answering the question “How much mass do I need to remove for this component to become a positive business case?”. This is done before any engineering work on the component.

3DN: What 3D printing technologies are supported by your solution?

We are completely technology-agnostic, meaning that we can set up any type of technology in the estimation profile. How this works is that once we have a new customer project, the initial setup includes configuring machine-specific parameters together with the customer. For example, labor costs and price of materials vary between companies and countries, the cost structures of WAAM are completely different to SLM, and all technologies require different types of post-processing. All technology- and company-specific parameters are considered and input before we start running assessments.

In addition, we bring instant real-market prices for the most prominent AM technologies like SLM, SLS, MJF, FDM, SLA, SAF etc. We also simulate and estimate the impact of nesting strategies and post-processing into the market prices.

SelectAM’s solution estimates production cost and time by analyzing numerous factors such as the impact of nesting or post-processing.

Our customers that have AM machines benefit greatly from the automated estimations and simulations to see which of their machines is the best fit for a given component, and what would be the cost and time to part. Also, simulating the impacts of nesting strategies, orientations, supports, re-designs, packing densities etc. gives our customers the answers needed as to which technology to use. Alongside this, we simulate the costs of conventional manufacturing methods to see where the break-even points lie to analyze at which stage of the product’s lifecycle should it be moved to or from AM.

In general, moving production to AM for the components it makes sense for will decrease the costs, waste and lead times. Re-designs will help with resource efficiency and sometimes even improve the performance of the parts. The move to AM also allows companies to make these parts just-for-demand. The list of AM benefits is long, but it starts with making the right choices, and we are here for that.

3DN: What is the role of machine learning and AI in your software? What transformative impact do you foresee AI having on the additive manufacturing sector in the coming years?

We can say that AI and machine learning play an important role in our background solution. The fact that we can perform accurate evaluations without CAD files means that the algorithm has to be intelligent. In addition, we get into process parameters and simulations, where we need intelligent technologies to do the “heavy lifting.” We predict and bet that AI will also play an important role in improving data quality. The question is not if the industry will transform, but rather WHEN. We are working hard to stay at the forefront of this development, and our customers should see some AI capabilities visible in the next larger version of our 2.0 platform.

The AM industry will also see more AI-based solutions around in-process monitoring and controls, topology optimizations, manufacturing execution systems (MES), capacity planning, and quality control systems. Also, computer vision and big data frameworks should be coming to the industry soon. There are many exciting opportunities to apply AI and other modern technologies into the AM industry, just imagine that one print job creates huge amounts of data that can be used to predict outcomes and optimize print processes, for example.

3DN: What are your current and future projects?

As anticipated, our development team is working hard on the creation of Platform 2.0. New features and capabilities will be introduced in 2025 that we will offer to the market. Some of these features will be free of charge. More specifically, we are working on artificial intelligence capabilities to address data-level issues and to further improve estimation and redesign analysis. We are also looking at a more automated workflow in the estimating process.

We are also currently working on some technology-specific projects. For example, we are working with a large manufacturer to optimize their WAAM operations. We were also involved in an “Impact Chain” project in which many SMEs participated in identifying, qualifying, and ordering AM parts in their early stages of adapting to additive manufacturing. Although our customers are global, we want to be active on our home turf in Finland, so we are also engaged with the Finnish Additive Manufacturing Ecosystem (FAME) and have interesting projects underway with them, with the goal of accelerating the Finnish 3D printing industry.

3DN: Any last words for our readers?

We’ve seen quite many customers who have, in the past, “burned their fingers” when trying to adopt AM into their workflows outside of R&D and tooling. Fortunately, with our approach, it is possible to stop wasting money, time, materials and energy. We can really help identify and justify valuable investments in additive manufacturing.

What do you think of SelectAM’s platform? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*All Photo Credits: SelectAM