#Startup3D: SAMGEN Unveils Its AI-Based Predictive Maintenance Software for Additive Manufacturing

The importance of artificial intelligence to optimize processes in Industry 5.0 is becoming increasingly evident. Even in the field of additive manufacturing (AM), we have seen a number of applications for AI, especially in software enhancement. From design to manufacturing, AI is used to improve existing processes and to create new ones. Experimenting with the use of AI combined with AM expertise, Berlin-based startup SAMGEN has come up with predictive maintenance software to optimize the maintenance of 3D printers.

Called PRAEDICTIO, the software will be officially launched on the market in the second quarter of 2025. The benefits of using software such as PRAEDICTIO are undoubtedly considerable for companies in the industry. It can help accurately predict the maintenance needs of 3D printers, optimize operations, avoid unnecessary downtime, and eliminate excessive use of spare parts, resulting in cost savings and improved machine performance.

To learn more, we interviewed Aymen Montasser, founder of SAMGEN. He told us more about PRAEDICTIO, its benefits for the 3D printing industry, and the company’s mission.

3DN: Could you introduce yourself and your connection with 3D printing?

Hello, I am Aymen Montasser, the founder of SAMGEN. At SAMGEN we develop innovative solutions for additive manufacturing. I began working in this field seven years ago, initially focusing on educating young scholars and conducting workshops in maker spaces on 3D design and 3D printing.

This experience led me to establish and manage 3D printing farms, including working with large-scale operations. Through these endeavors, I identified several challenges in the 3D printing industry that need attention and can be effectively resolved.

SAMGEN team. From left: Esin Seçil ÇOMAK, Aymen Montasser and Sajed Mejri.

3DN: What is SAMGEN’s mission?

At SAMGEN, with our predictive maintenance product PRAEDICTIO, we aim to redefine the standards of machine maintenance. Our journey begins with the field we know best: additive manufacturing. By leveraging cutting-edge technology, we strive to make maintenance smarter, more efficient, and data-driven, paving the way for innovation and reliability in industrial operations.

3DN: Could you explain how the PRAEDICTIO software works?

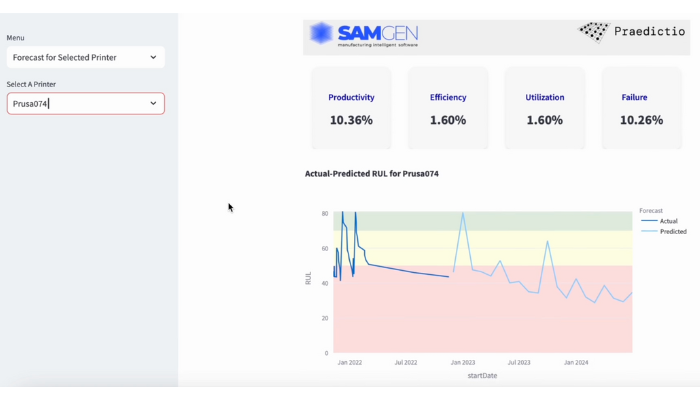

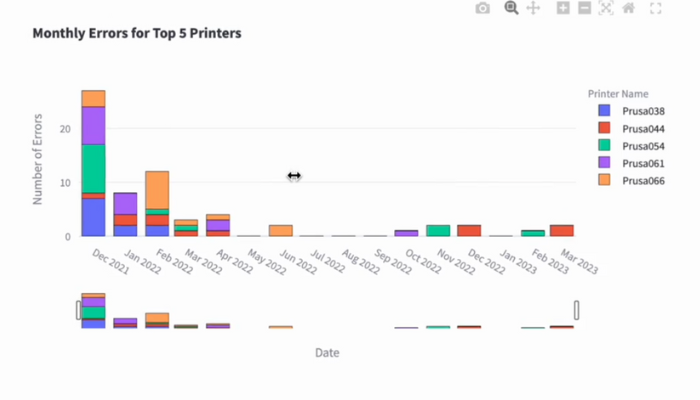

Praedictio is a cloud-based software that uses advanced algorithms to continuously monitor and assess the wear and tear of key components, such as the heating bed, fans, and sensors. After evaluating various methods, including optimization algorithms and predictive analytics, we concluded that our AI model is the most promising approach. This strategic approach allows us to leverage historical data and provide accurate predictions regarding the lifespan and condition of critical components in 3D printing operations.

The software provides accurate predictions of the Remaining Useful Life (RUL) of machines.

3DN: What advantages does PRAEDICTIO offer users over traditional maintenance?

PRAEDICTIO provides significant customer benefits by transforming traditional maintenance into a data-driven approach, enabling customers to maximize their equipment’s efficiency. With accurate RUL Remaining Useful Life) predictions, customers gain insights into how long each printer and its components are likely to function optimally, helping them plan maintenance with their service provider. The main benefits are:

- Proactive Machine Maintenance Scheduling: Customers will be able to avoid random maintenance on their 3D printers, even without specialized expertise, by clearly understanding when maintenance is actually required. Additionally, customers can schedule their maintenance proactively, addressing potential problems in advance and avoiding the disruptions of unexpected breakdowns. This proactive approach helps them keep production on schedule, boost productivity, and maintain a steady workflow.

- Maintenance Cost Reduction: Predictive maintenance minimizes both the frequency and intensity of repairs by scheduling maintenance only when needed, rather than at fixed intervals. This approach helps customers avoid unnecessary service costs and resource use. In our use case, we have demonstrated that predictive maintenance can reduce maintenance costs by up to 30%, allowing customers to save on labor, parts, and other resources, resulting in a more efficient and cost-effective maintenance strategy.

In addition, our solution goes beyond predictive maintenance. It enables users to identify complex patterns within their operational data that are often missed by traditional analysis. This deep insight empowers customers to make data-driven decisions, enhancing their operational efficiency and setting the foundation for long-term success and growth.

3DN: What markets is SAMGEN targeting?

We are starting with the market closest to us. Living in Germany, we recognize that the 3D printing market here is one of the largest in the world. Our goal is to establish ourselves firmly in this market first. Once accomplished, we plan to expand into the American market, exploring how our solution can be applied to different industries as well.

Proactive scheduling of machine maintenance allows time and resources to be optimized.

3DN: In the past, you were also dedicated to AM process planning and automation. How important do you think it is today to make AM more scalable and automated?

The AM process still heavily depends on how the manufacturer designs their machine and determines which systems it should be connected to. While the idea of automating the system is both innovative and essential, we are seeing a trend where more manufacturers are closing their ecosystems. This limits users’ freedom to choose which printers and types of printers they want, ultimately forcing them to base their entire workflow on a single printer manufacturer.

We faced this issue last year while developing our scheduling module. Obtaining APIs to connect to different machines was a significant challenge and a major roadblock in our efforts to automate workflows. This limitation negatively impacts the industry by restricting the flexibility needed for a truly automated and efficient process. To foster innovation and efficiency in automation, it is crucial to have open access to machines. This openness enables the creation and automation of workflows that are adaptable and not tied to a single manufacturer. I believe this is the most important aspect of driving creativity and progress in automation for the AM industry.

3DN: What are SAMGEN’s plans?

We are currently focusing on our PRAEDICTIO module, which will be officially launched on the market in the second quarter of 2025. With it, we aim to revolutionize the standards of maintenance in the 3D printing industry.

3DN: Any last words for our readers?

We believe that the future of manufacturing lies in additive processes, and with that, we see preventive maintenance becoming obsolete. Instead, we must leverage the data gathered from printers to make them more robust, automated, and independent. Utilizing AI in 3D printing machines has the potential to revolutionize the industry by enabling printers to operate autonomously and efficiently. Click HERE to learn more about SAMGEN.

What do you think of SAMGEN and its predictive maintenance software PRAEDICTIO? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! If you are looking for more 3D printing in aerospace & defense content, check out our dedicated page HERE. Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.