#Startup3D: FIDENTIS Redefines Dentures with Multi-Material 3D Printing

Dentistry is a field where precision, aesthetics and functionality must coexist in perfect harmony. This technically demanding sector has benefited greatly from advances in 3D printing. Among the young companies transforming dental production methods, FIDENTIS® stands out. A spin-off from the Fraunhofer IGCV institute, this start-up has attracted attention with a multi-material 3D printing solution specially designed for telescopic prostheses. Their technology goes beyond current standards: it combines laser powder bed fusion with a robotized system capable of depositing other materials in the same process. We recently spoke to Max Horn, co-founder and CEO of FIDENTIS, to learn more about their approach.

3DN: Can you introduce yourself and tell us how FIDENTIS was born?

FIDENTIS® was born as a spin-off from Fraunhofer IGCV, recognized worldwide as one of the leaders in multi-material additive manufacturing research applied to metals. As a researcher at this institute and doctoral student at TUM, I contributed, alongside my colleagues, to the development of this innovative technology back in 2017. Today, we are using this very process to produce dental prostheses.

The FIDENTIS team. From left to right: Max Horn, Timo Schröder, Lukas Langer and Johannes Lauer.

3DN: Why have you chosen to focus on dentures?

A few years ago, Josef Schweiger—one of Germany’s most renowned dental technicians—discovered our manufacturing technology, originally developed for sectors such as aeronautics and toolmaking. He immediately saw its potential for the dental industry. Since then, we have pooled our skills and, with our respective teams, are continuing to develop this technology to make it compatible with precious metals and capable of meeting the exacting standards of dental prosthetics.

Currently, dental production still too often relies on inferior solutions, particularly those lacking friction telescopes, which are essential for guaranteeing precise fit and impeccable aesthetics in the mouth. Our mission is clear: to support dental laboratories in the industrialization of high-quality prostheses. By leveraging advanced additive manufacturing technologies, we are helping to fill the growing shortage of qualified prosthetists while raising industry standards.

3DN: Can you explain your multi-material 3D printing process?

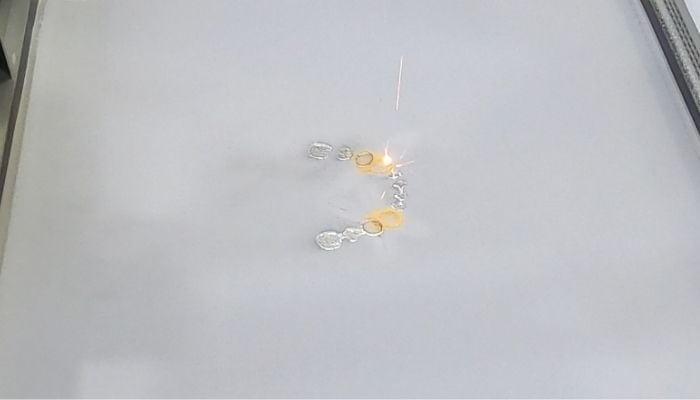

Our multi-material solution is based on the laser powder bed fusion (L-PBF) process, which enables two or more alloys to be combined in a single component. A robotic arm intervenes with precision to deposit the additional powders in the bed, in perfect synchronization with the manufacturing process. We also develop tailor-made laser and scan path parameters to ensure optimum fusion between the materials and obtain fully dense parts with high dimensional fidelity.

A fully integrated digital production chain then enables automated post-processing of functional surfaces, all from a single data model. Our technology represents a truly unique advance in the field. And beyond the dental sector, we look forward to exploring the many possibilities offered by multi-material additive manufacturing in other industries.

The process developed by FIDENTIS is 10 times faster than traditional methods.

3DN: What are the challenges of simultaneous 3D printing with different metals? How does FIDENTIS address these challenges?

Compared to single-material 3D printing, multi-material additive manufacturing is at least three times more complex. It’s no longer just a matter of mastering one material, but two (or more), as well as their interactions at the interface. This complexity is reflected at every stage of the process: from data preparation to monitoring during printing (scanning, powder deposition, etc.), right through to post-processing (heat treatment, machining, powder recycling, etc.). We have been working on multi-material additive manufacturing for over seven years and have developed solutions that structure and stabilize the entire process, guaranteeing reliable, reproducible production. Despite this, even single-layer scan paths can be very complex to analyze at first glance.

On a more global level—and particularly in our case—the European regulatory framework represents a considerable challenge. It is, of course, essential that patient safety and well-being remain at the heart of any technological advance. Nevertheless, the level of rigidity of the legal framework, as well as its enforcement, holds back innovation and imposes a significant burden, not only on us as a startup but also on the entire ecosystem. Faced with a shortage of qualified professionals and rising costs in the healthcare sector, our society must learn to adopt a more flexible and pragmatic approach to innovation.

3DN: What future plans does FIDENTIS have?

The enthusiastic response from industry experts confirms that we are moving in the right direction and encourages us to pursue our efforts with determination. Our next big step is to make our first patients smile. As soon as the first prostheses have been delivered, we plan to ramp up, optimize our production and further improve our efficiency.

3DN: Any last words for our readers?

Thank you to everyone who has supported us and continues to support us along the way. Without the enormous support of experts, mentors, etc., we wouldn’t be where we are today.

If you’d like to learn more about the FIDENTIS denture process, we invite you to visit their official page, HERE. What do you think of FIDENTIS technology? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel. If you are interested in more 3D printing news in the medical and dental sector, click HERE.

*All Photo Credits: FIDENTIS