3D startup of the month: Voodoo Manufacturing, proving that 3D printing factories are here to stay

Each month the 3Dnatives team searches across the globe for the latest startups in 3D printing that are helping to revolutionize the industry as we know it. This month, we have chosen Voodoo Manufacturing; the New York startup who are developing 3D printing “micro-factories”, bringing a new look to customer personalization. To help learn more about this innovative startup, we spoke to Jonathan Schwartz, the Co-Founder of Voodoo Manufacturing, to have an in-depth look at Voodoo Manufacturing and to delve deeper into what they see for the future of 3D printing.

3DN: Can you tell us a little bit about your first approach to 3D printing? How exactly did you come up with the idea for Voodoo Manufacturing?

In the beginning we had two unique insights, which led to the founding of Voodoo Manufacturing. The first had to do with desktop 3D printers, which you could call a low-end commodity that are capable of producing end-use parts and products, as long as the application was used correctly. The second insight we had was that with the proper software and technology infrastructure, it would be possible to build a high-volume factory that is full of these commodity machines that could compete, in terms of costs, against injection molding for low-volume rates.

- Jonathan Shwartz, Co-Founder and CPO

- Max Friedfeld, Co-Founder

- Oliver Ortlieb, Co-Founder

- Patrick Deem, Co-Founder

3DN: What kind of services can a company expect from a 3D printer micro-factory?

At Voodoo Manufacturing, there are 4 main services that we offer: Direct Print, Volume Print, 3D Design, and our Print API. With Direct Print, anyone from an engineer to a student can upload a 3D printable CAD file directly to our site and get an instant quote for the 3D printed part. Using this service, you can currently order up to 100 units. The Volume Print service is reserved for orders that are more than 100 units or for projects that require a higher degree of involvement from our team. The applications for these projects can run from promotional giveaways to end-use hardware components. Our 3D design service is pretty self-explanatory. Those that are in need of 3D design help can work with our team of seasoned 3D modelers and CAD professionals that will turn their concept into a ready-to-print design. Lastly, with Print API, you are able to plug into our internal system and automatically route your orders from a website or application directly to our factory. From there, we will manufacture, package and ship either back to you or to your customer.

3DN: What are Voodoo Manufacturing’s goals for the next 10 years?

We like to call ourselves the “AWS for Manufacturing”, so our goal is to make manufacturing more like software in the sense that you can easily scale production up or down at the turn of a dime. In the same light, we are hoping to help democratize manufacturing and make it accessible to anyone who wants to make a physical part or product. Given the rate at which 3D printing technology is advancing, we don’t think that it will be too long before we are directly competing with traditional manufacturing methods; like injection modeling for runs of up to 100k units, or eventually 1 million.

3DN: In your opinion, how do you see 3D printing changing how industries develop today?

3D printing is already impacting today’s manufacturing industry. To begin, when you compare other manufacturing methods, 3D printing has a very low barrier for entry. The molds required for injection molding generally start at a few thousand dollars, and that’s for very small parts. With 3D printing, the only thing that you need in order to get off the ground is a 3D model of your product.

With 3D printing, you don’t need to place orders for hundreds of thousands of products at once. Instead, you can manufacture the items as you need them. This cuts down on the cost of storing inventory and mitigates the risk of overproduction.

Lastly, 3D printing allows for faster prototyping and speeds up innovation cycles. At the beginning of a long product development journey, spending a few thousand dollars on a model that can’t be changed is expensive and will slow you down. With 3D printing, you can easily edit the 3D model file and instantly print out the new version of your product.

3DN: Do you have any last words for our readers?

We deeply believe in a digital future for manufacturing, where lead times are short, innovation cycles are fast, molds are not required, and runs can be scaled instantly. We think this is the biggest change to manufacturing in the last 50 years.

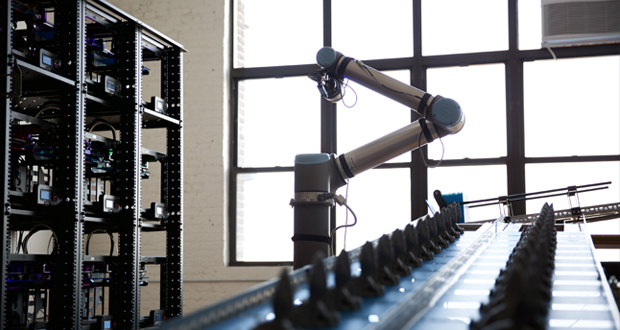

Check out the video below of the Voodoo Manufacturing Skywalker project, a robot that streamlines work within the micro-factory:

https://youtu.be/GoNRTucoErE

To learn more about Voodoo Manufacturing, be sure to check out their website here.

What do you think of Voodoo Manufacturing? Do you think that they are recreating the future of 3D printing? Let us know by leaving a comment below or on our Facebook and Twitter pages!