#3DStartup: AMendate develops topology optimization software

Not only the printers and filaments play a crucial role in additive manufacturing. Equally important is the software with which the models are edited. For this, AMendate developed a topology optimization software. Topology optimization is a process by which basic shapes for components are determined and optimized.

Their software makes it possible to create optimal parts for 3D printing almost fully automatically. The focus is on speed and it should greatly simplify the optimization processes in 3D printing. To find out more, we asked Thomas Reiher, CEO and co-founder of AMendate, some questions.

3DN: Can you introduce yourself and tell us about the founding of AMendate?

Thomas Egret; CEO and co-founder of AMendate

AMendate is software for simple and fully automatic optimization of technical components for additive manufacturing. This replaces the currently very complex processes for producing lightweight geometries. The idea for the development of the software came to us during our work at the university and the local research center for additive manufacturing. 3D printing offers many opportunities for lightweight construction through the cost-efficient production of bionic structures.

As part of my research for my dissertation, I have been involved in the creation of such complex structures. At the same time, our co-founder Steffen Vogelsang developed this idea with me over a period of three years into a functioning technology that met with great interest among many companies. So we decided to push the project professionally and full time as a start-up. As a result, we applied for an EXIST scholarship and were positively evaluated. Since July 2018, three people from our team have been financed by it and we were able to move into garage33, the incubator of the University of Paderborn. In our own garage and can now really get started.

3DN: What exactly does AMendate’s topological optimization technology have in store?

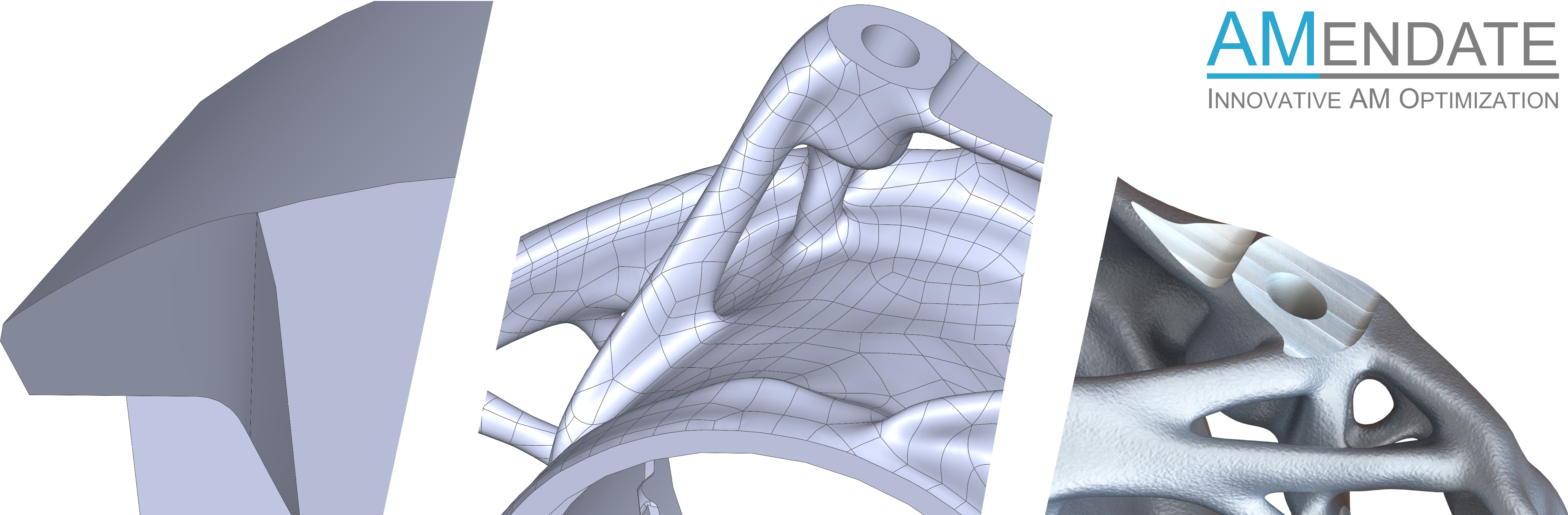

AMendate is a software solution for the fully automatic optimization of technical components. It creates organic-looking lightweight structures that realize material-saving, efficient and cost-effective production with additive manufacturing. Our solution thus represents a previously unavailable tool to optimally exploit the design freedom of additive manufacturing and to design high-quality components automatically and quickly.

3DN: What are the advantages of your software and what is it especially suitable for?

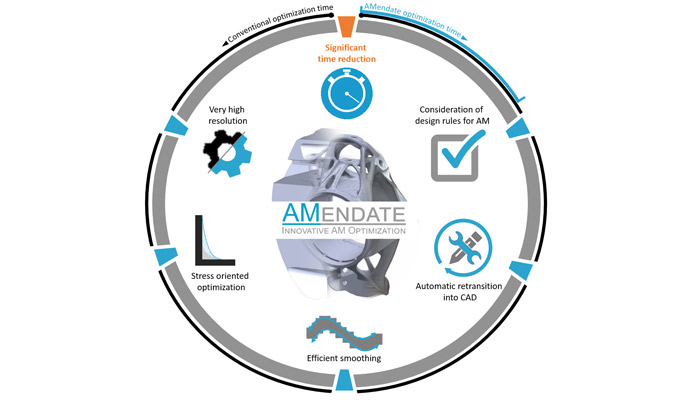

The AMendate technology enables a particularly fast generation of complex lightweight structures without the otherwise necessary manual effort in the interpretation of the simulation results. The core element is therefore an automatic interpretation and subsequent transfer to common CAD exchange formats instead of hard-to-process surface models of other software solutions. The user is thus generating in a unique manner within a short time in his known technical data workflow a usable component. Which is optimally adapted to the loads, reduces the use of materials and can be used without conversion losses in everyday business. With only one software in just one step.

The software is therefore suitable for all those who want to save material and weight and rely on additive manufacturing. We simplify and accelerate the process significantly, so that even companies without their own calculation department can carry out component optimization cost-effectively and quickly. We are up to 80% faster than conventional processes and achieve average weight savings of over 40% with a directly achievable optimization result.

3DN: What are the next goals of AMendate?

Of course, as a very young startup we are currently focusing on the first steps of starting a business. At the same time, we are already working for a pilot customer, with whom we will be going online soon. At the upcoming formnext trade fair, we would like to present ourselves to the trade audience and win customers.

With the software we work with high pressure on the further development and implementation of new modules with further interesting features. Our vision is generative design: a large number of different optimization approaches are generated and briefly calculated by automatic variation of various parameters. The user can then select the most promising one and have it calculated completely. And all in a short time!

With their idea the team of AMendate qualified for the Rapid. Tech start-up award and won the second place

3DN: How do you see the future of additive manufacturing, especially with regard to software developments?

Additive manufacturing will find its place and complement the other manufacturing processes. How fast and how extensive this happens is partly due to the hardware development of the machine manufacturers, but also to the software. The way of thinking about bionic structures still has to be anchored sufficiently in the engineers and then also appropriate CAD tools must be available. Here we would like to make our contribution, in which we extend the construction by certain automatisms, in order to be able to really use the additive manufacturing.

3DN: Do you have any last words for our readers?

It is impressive how additive manufacturing has already questioned old processes and ways of thinking and opened up new possibilities in the past ten years. We are convinced that this was only the beginning and that the technological revolution will really take off in the next ten years. We are happy to help shape this exciting development.

More information about the software can be found on the official website of AMendate.

What do you think about AMendate and their software? Let us know in a comment below or on our Facebook and Twitter pages! And remember to sign up for our free weekly Newsletter, to get all the latest news on progress, research and more entrepreneurs in 3D printing send straight to your inbox!