SpaceX Optimizes Raptor 3 Engine With the Help of DfAM and 3D Printing

Elon Musk has not only caused a stir in the last week with inflammatory statements on social issues as well as his growing support for Donald Trump’s re-election, but also with a new announcement about the production of the Raptor 3 engine by SpaceX, his aerospace company based in Hawthorne, California. More specifically, it seems that this new SpaceX engine has been further improved using metal 3D printing and DfAM. But how?

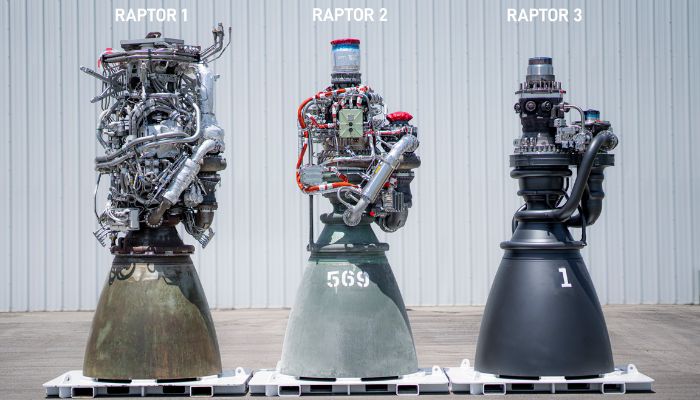

For those who may not be closely following the new commercial space race, SpaceX is developing the Raptor rocket engine for its Starship mission. The engine will use a full-flow staged combustion cycle to power a rocket. SpaceX has already unveiled two versions of Raptor, but the latest third edition stands out for its slimmed-down design and improved features.

Raptor 3 has a simplified and optimized design. This was achieved through AM and DfAM, among other things

According to SpaceX, the Raptor 3 engine will have integrated cooling and secondary flow circuits. The engineers have succeeded in designing Raptor 3 in such a way that many of the otherwise external components could be relocated to the inside. This eliminates the need for bolted connections and heat shields, helping to reduce weight as well as streamline the look of the engine.

DfAM and additive manufacturing with metals were partly responsible for the optimized design. Elon Musk tweeted that SpaceX has “the most advanced 3D metal printing technology in the world”, but was vague about exactly which process this is. Laser powder bed fusion and DED are generally considered to be common processes used at SpaceX. However, Musk’s statement leaves room for speculation as to whether the technologies used are in-house processes, a well-known provider of 3D printing solutions or a combination of both.

In any case, it is clear that AM has helped to simplify and improve the design, which also has a positive impact on the performance of the Raptor 3 engine. Musk comments on this as follows: “It’s important to note that while the induced mass (…) of Raptor 3 is much better than Raptor 2, there is still a lot of room for improvement. The thrust on Raptor 3.x will be over 300 tons (thrust/mass>200), allowing for a thrust of 10,000 tons at launch. (…) We are approaching the limit of known physics.”

Despite the improvement, Raptor 3 will not be the final Raptor version and Raptor 4 will show up with additional improvements. However, if we look at advancements up until now, it does seem likely that SpaceX will continue to turn towards metal 3D printing as well as design optimization to make the best possible engines.

What do you think of the new Raptor 3 engine? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly newsletter here for the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*Cover Photo Credits: SpaceX