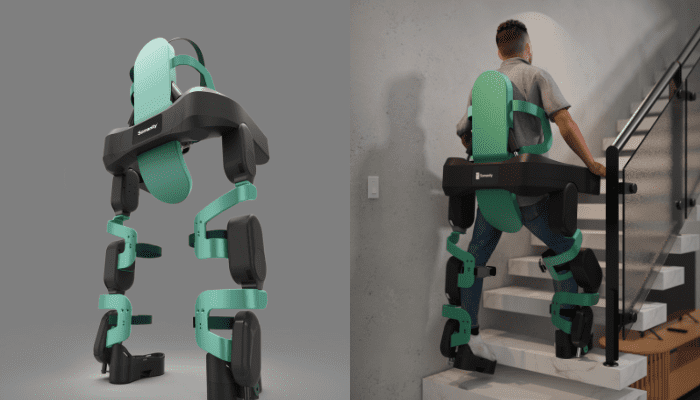

Somanity Develops 3D Printed Exoskeletons for People with Disabilities

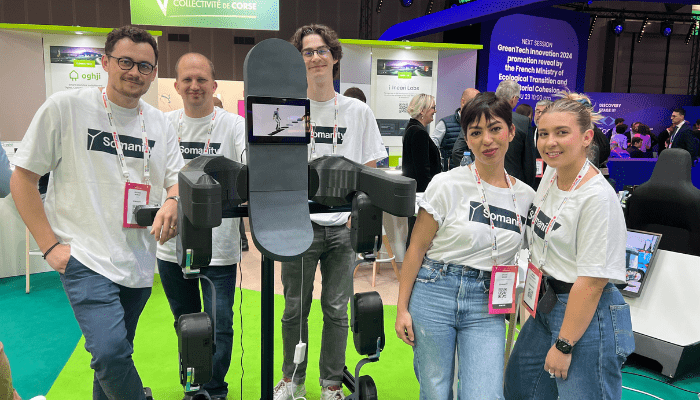

3D printing is steadily transforming the medical field, offering innovative solutions that enhance the quality of life for people with disabilities. From customized prostheses to adapted keyboards, this technology is opening new possibilities. Yet, one of the biggest challenges for individuals with motor disabilities remains independence and mobility. This is where the French company Somanity makes a difference. They are developing fully 3D-printed exoskeletons, creating personalized devices designed to improve both mobility and daily life. To learn more, we had the chance to speak with Mathieu Veran, founder and CEO of Somanity.

3DN: Can you tell us about Somanity and your connection to additive manufacturing?

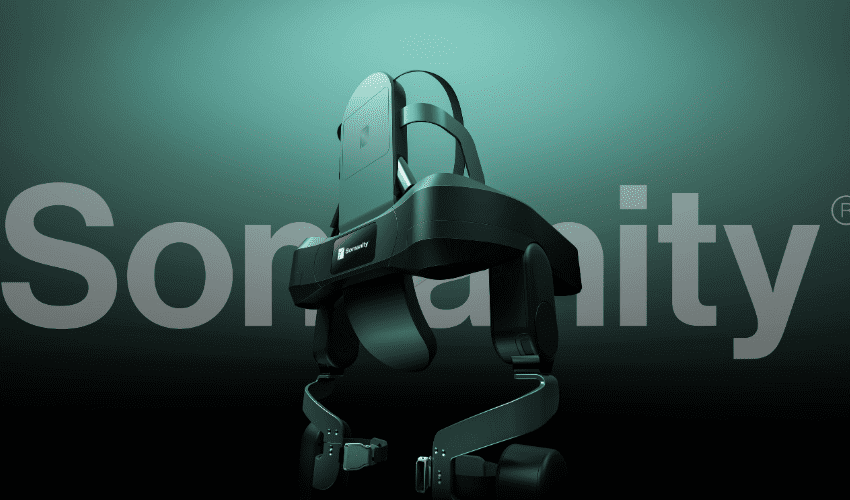

Somanity is an innovative company dedicated to designing and manufacturing fully 3D-printed exoskeletons. Our mission is to restore mobility and independence to people with motor disabilities. By integrating additive manufacturing technologies, we can create customized devices that precisely meet the needs of each user. The flexibility and precision of 3D printing allow us to push the boundaries of traditional design and offer cutting-edge, personalized solutions.

3DN: Why did you decide to make extensive use of 3D printing?

We chose 3D printing because it offers virtually unlimited possibilities in terms of design and customization. This technology allows us to create exoskeletons that are perfectly adapted to the specific morphology and needs of each user. In addition, 3D printing significantly reduces production time and costs associated with manufacturing prototypes and small batches. By adopting this approach, we can also quickly incorporate improvements and adjustments in response to user feedback.

3DN: What 3D printing processes and materials do you use to create your exoskeletons?

We mainly use Volumic 3D’s FDM process and selective laser sintering (SLS). Volumic 3D’s FDM is preferred for its reliability, precision, and ability to work with a wide range of materials. SLS is chosen for its ability to produce parts with exceptional mechanical properties and great design freedom without supports. The materials we use include PETG and Nylon PA12, which offer an optimal combination of lightness, strength, and durability, essential for the comfort and effectiveness of exoskeletons.

3DN: What are the advantages of 3D printing over traditional manufacturing methods for these devices?

3D printing has many advantages over traditional manufacturing methods. First, it allows for extensive customization, which is essential for creating exoskeletons tailored to each individual. Second, it reduces costs and development time by eliminating costly mold-making steps and enabling rapid iterations. In addition, 3D printing offers great design freedom, allowing the creation of complex, optimized structures that traditional methods cannot achieve. Finally, it enables more sustainable production by reducing material waste.

3DN: What are Somanity’s future goals and projects?

Our future goals include continuously improving our exoskeletons to make them even lighter, more robust, and more comfortable. We are also working on integrating new technologies, such as advanced sensors and artificial intelligence systems, to improve interaction between the user and the exoskeleton. Another area of development is the refinement of our motor block using new 3D-printed gearboxes, which will further improve the performance and efficiency of our devices. In addition, we plan to develop solutions for a wider range of disabilities and specific needs by expanding our product offering and exploring new markets.

3DN: Any final words for our readers?

At Somanity, we firmly believe that technology should serve people. Our commitment is to transform the lives of people with reduced mobility by offering them innovative and personalized solutions. 3D printing allows us to realize this vision, and we are excited about the future and the possibilities it offers us. We thank all our supporters and partners, and we look forward to continuing this adventure together, pushing the boundaries of what is possible.

What do you think of Somanity? Let us know in a comment below or on our LinkedIn or Facebook pages! Plus, don’t forget to sign up for our free weekly Newsletter to get the latest 3D printing news straight to your inbox. You can also find all our videos on our YouTube channel. Interested in more medical and dental 3D printing news? Visit our dedicated page HERE.

*All Photo Credits: Somanity