CAM Specialist SolidCAM on Its Entry Into the Additive Manufacturing Market

SolidCAM is a long-term player in the field of computer-aided manufacturing. It has developed a CAM solution for all machining applications, that integrates seamlessly with several world-renowned CAD software packages, mainly SolidWorks and Autodesk Inventor. Its iMachining module dramatically reduces manufacturing time, increases tool life and productivity for all CNC machine users, providing an iMachining Wizard that automatically calculates optimal cutting conditions for all stock materials, cutting tools and CNC machine types. Most recently, SolidCAM entered the additive manufacturing market, more specifically metal 3D printing. The company recently introduced Desktop Metal 3D printing solutions, combining two production methods, additive and substractive,. For SolidCAM, additive manufacturing is an excellent complement to subtractive CNC manufacturing; thus, it hopes to solve all complex manufacturing problems and offer real added value to its customers. We sat down with Dr. Emil Somekh, SolidCAM’s founder and CEO, to learn more about this strategic shift and the company’s ambitions.

3DN: Could you introduce yourself and SolidCAM?

My name is Emil Somekh and I am the Founder and CEO of SolidCAM, an independent, international Computer Aided Manufacturing software company. Since 1984 we have been revolutionizing the way CNC machines operate through our CAM software solutions and patented iMachining technology.

Emil Somekh (photo credits: Sidney Eisner)

3DN: Why did SolidCAM turn towards additive manufacturing?

SolidCAM views additive as a complement to our subtractive CNC manufacturing customers. Over the last few years, we have witnessed incredible innovation in metal 3D printing and have committed to becoming a leading resource in the space. The ability to print complex metal parts with speed and repeatability is now within reach of even the smallest CNC job shops. SolidCAM Additive was formed to assist our customers in adopting additive technologies and utilizing it to its full potential with the same level of renowned worldwide technical support SolidCAM is known for.

3DN: Why did you choose to partner with Desktop Metal?

Through their Shop system, Desktop Metal was the first to introduce metal additive manufacturing, utilizing Binder Jetting, that is accessible to all job shops. They have invested heavily in simplifying a complex process to allow for increased productivity and throughput of metal parts, with limited operator involvement. With a bright future and a growing list of complementary AM products, Desktop Metal was the perfect partner for SolidCAM to expand into additive manufacturing.

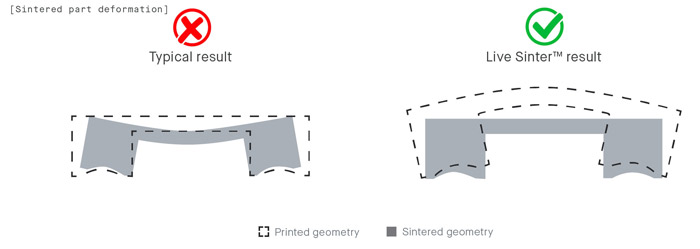

Live Sinter allows users to obtain parts without defects coming out of the sintering furnace

3DN: Could you remind us of the main benefits of Desktop Metal’s technology?

Desktop Metal has invested in a holistic approach to develop AM, from the creation of proprietary metal powders to the sintering of parts in their advanced Furnace solution. At SolidCAM we understand that hardware is only as good as the software empowering it and Desktop Metal delivered the first-of-its-kind Live Sinter application. Developed in collaboration with Desktop Metal’s world-class material science team, Live Sinter uses a unique, multi-physics engine capable of simulating the complex forces and deformation parts experience during sintering, and in just minutes generates “negative offset” geometry which, when sintered, results in straight, defect-free parts, right out of the furnace.

3DN: How does SolidCAM see the complementarity of AM and CNC machining?

Additive manufacturing and CNC machining both have their advantages and limitations. Through combining the two technologies, companies can solve complex manufacturing problems in new and innovative ways. Metal 3D printing will still need post processing utilizing CNC machining, to ensure the parts are to the finish specifications and tight tolerances the customer requires. SolidCAM is positioned as the leader in CAM solutions, adapting its software technology to effectively post process the growing market of additive parts.

By combining CNC machining and additive manufacturing, it is possible to obtain very complex geometries (photo credits: SolidCAM)

3DN: How do you see the future of metal additive manufacturing?

It is an exciting time for metal additive manufacturing. We see the industry growing quickly as companies begin to understand the advantages 3D printing brings in productivity and capabilities, previously unattainable with CNC manufacturing. SolidCAM will lead the way in providing the knowledge and resources necessary for our customers to leverage AM to its full potential.

3DN: Any last words for our readers?

If your company is looking into metal additive manufacturing, don’t go at it alone. SolidCAM is here to support you both locally and internationally, to ensure you are at the forefront of the additive revolution and gain the competitive advantages metal 3D printing offers. You can learn more on our website HERE.

What do you think of SolidCAM’s strategy? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*Cover Photo Credits: SolidCAM

my normal comment is