Solar Gate: The First 4D-Printed Adaptive Façade System

Indoor comfort generally requires a high energy input, which means that buildings account for a significant proportion of global carbon emissions. In 2020, for example, single-family homes consumed an average of 864 petajoules of heating energy, an enormously high figure. Researchers at the Universities of Stuttgart and Freiburg have now developed a promising solution to reduce this energy requirement for heating and cooling: a self-sufficient façade system that adapts independently to changes in the weather thanks to 4D printing. What’s more, the project is biomimetic, which means it was inspired by nature.

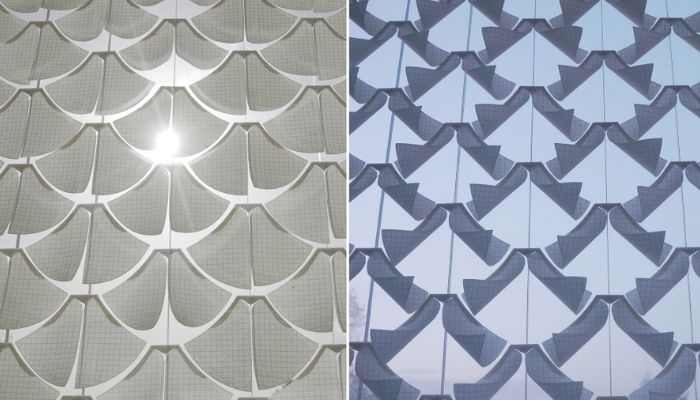

Solar Gate is the world’s first adaptive shading system that works depending on the weather and does not require energy from an electrical drive. The pine cone, whose scales open and close in response to changes in humidity or temperature without consuming metabolic energy, served as a model. Based on this principle, the team reproduced the direction-dependent structure of cellulose in plant tissue using 3D printers.

Thanks to bio-inspired 4D printing and cellulose materials made from renewable raw materials, the team has developed a system that automatically adapts to changes in the weather. (Photo credit: ICD/IntCDC University of Stuttgart)

“Weather-responsive architectural façade systems usually rely on complex technical devices. Our research investigates how we can harness the responsiveness of the material itself through computer-based design methods and additive manufacturing. We have developed a shading system that opens and closes independently depending on weather conditions, without the need for any operating energy or mechatronic elements. The biomaterial structure itself is the machine,” explains Professor Achim Menges, Head of the Institute for Computer-Based Design and Construction and spokesperson for the Cluster of Excellence Integrative Computer-Based Design and Construction for Architecture at the University of Stuttgart.

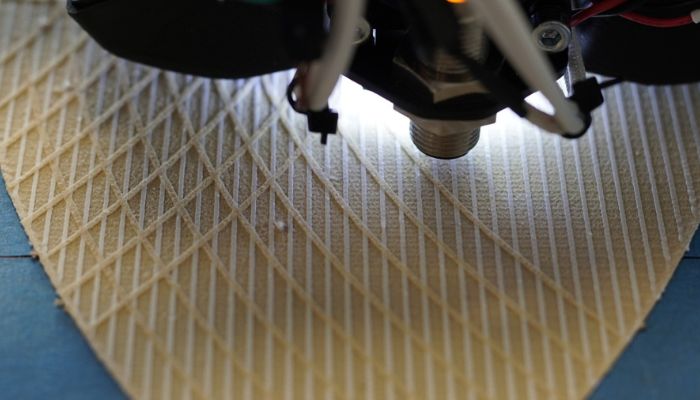

Cellulose was chosen because it is a renewable material that is abundant and reacts to changes in humidity by swelling or shrinking. This property is known as hydromorphism and is widespread in nature, such as in pine cones. The team took advantage of this property and fabricated bio-based cellulose fibers to create a two-layer structure inspired by the scales of the pine cone using 4D printing, which can change shape on its own in response to external influences.

For Solar Gate, the researchers also developed a computer-protected manufacturing method for controlling the extrusion of cellulose materials using a standard 3D printer. This method takes advantage of the self-forming behavior of 4D-printed material systems. The printed elements can curl or open, and at low humidity, the cellulosic materials release their moisture and contract, causing the printed elements to flatten and close accordingly.

The two-layer structure is produced from cellulose-containing materials (Image: ICD/IntCDC University of Stuttgart)

“Inspired by the hygroscopic movements of pine cone scales and the bracts of the silver thistle, the Solar Gate has succeeded in transferring not only the high functionality and robustness of the biological models into a bio-inspired shading system but also the aesthetics of plant movements. This can be regarded as the ‘royal road of bionics’, as everything that fascinates us about the biological source of ideas has also been realized in the bio-inspired architectural product,” says Professor Thomas Speck, head of the Plant Biomechanics Group Freiburg and spokesperson for the Cluster of Excellence Living, Adaptive and Energy-autonomous Materials Systems (livMatS) at the University of Freiburg.

But how is Solar Gate integrated into the architecture? The functionality and durability of the system have already been tested for a year under real weather conditions. It was then attached to the livMatS Biomimetic Shell, the building demonstrator of the Cluster of Excellence IntCDC and the Cluster of Excellence livMatS, which serves as the research building of the University of Freiburg. In addition, the 4D-printed shading system is installed on a south-facing skylight and thus supports the building’s climate regulation.

More specifically, the elements open in winter to let sunlight into the building and warm it up, while they close in summer to prevent overheating. The entire process is controlled solely by changes in the weather, which could mean a huge advance in architecture in the future, while also demonstrating the potential of additive manufacturing and cellulose as a material. Find out more about Solar Gate HERE.

What do you think of Solar Gate? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*Cover Photo: ICD/IntCDC University of Stuttgart